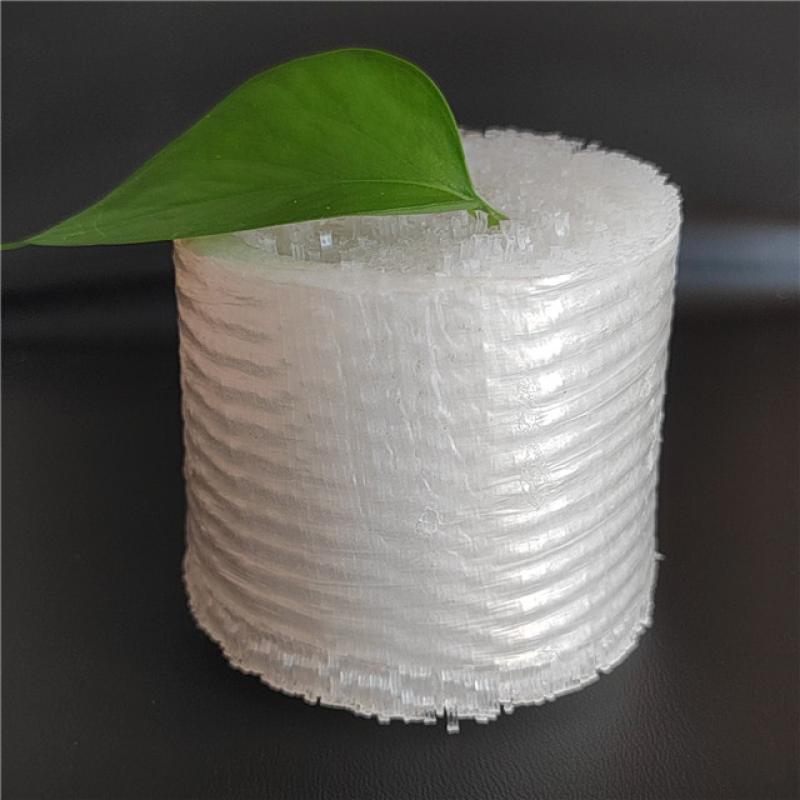

Product DetailsHdpe geocell is made from a brand new form of high electricity geosynthetic, that's popular with both domestic and abroad, in accordance with gb/t 19274-2003 implementation of the requirements, which welding the bolstered hdpe sheets via way of the excessive-strength ultrasonic and forming to be a structure of three-dimensional reticular formation this is without problem folding.And handy for transportation.Even as it is be in introduction,the hdpe geocell can be pull right into a network and launched right into a 3-dimensional honeycomb grid.Because it filled in sol,macadam

Contact Now

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Contact Now

Application Of Polypropylene Fiber Reinforced Concrete Polypropylene fiber is also known as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. Polypropylene (PP) is a semi-crystalline thermoplastic.

Contact Now

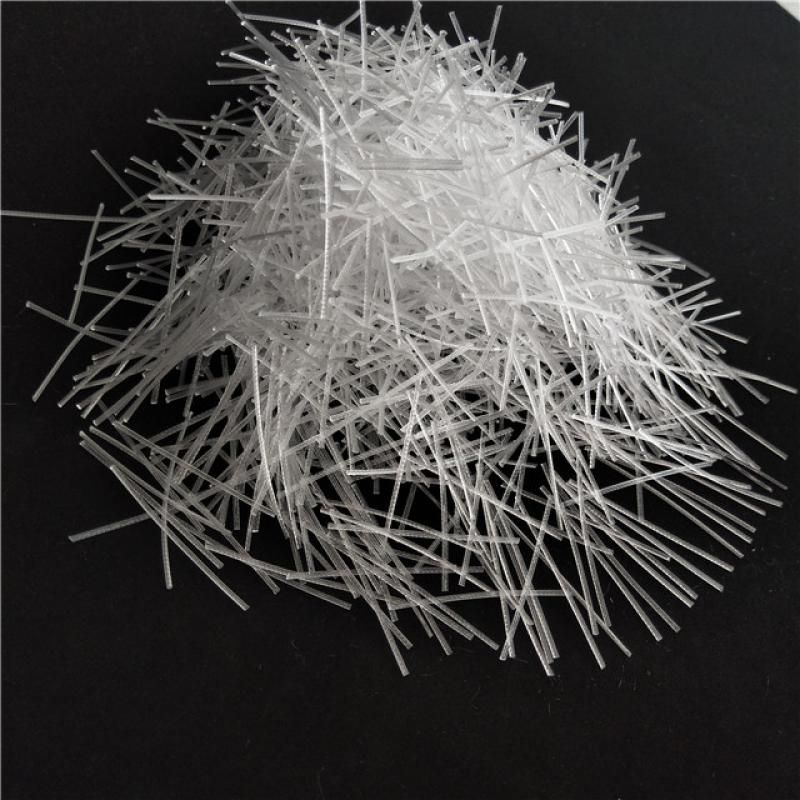

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

40 MM High Performance Structural Synthetic Macro FibersProduct Details Concrete pp fiber is made by a hundred% virgin polypropylene,adopting unique production system to make high power bundle monofilament fiber. When the fiber is positioned into the concrete,concrete (or mortar) can efficaciously manipulate concrete (or mortar) Micro-cracks which is caused by plas

Contact Now

Polypropylene Twisted Bundle Fiber Reinforced ConcretePolypropylene twisted bundle fiber reinforced concrete is widely used in concrete engineering.Bundle twisted PP fiber is developed for replacement of steel fiber.It has more advantages in concrete structures,except the characteristics of ordinary steel fiber.With polypropylene as its raw material,it is producted by special drawing twisting and surface treatment.It has good acid and alkail resistance.Twisted bundle pp fiber has high strength,Polypropylene twisted bundle fiber has very good corrosion resistance and anti-aging ability.Excellen

Contact Now

Product Details As a new type concrete-strengthening fiber, it becomes a new popular subject in the field of fiber concrete application after glass fiber and steel fiber. Reinforced Functions to Concrete: compared with steel fiber, full-dispersed polypropylene fiber has advantages in its thinness, large amount, non-water absorbency, strong acid & alkali resistance and similar elastic modulus with that of concrete.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)

Contact Now

Polypropylene PP Twisted Fiber Macro Fiber For ConcreteWhat is polypropylene PP Twisted Fiber?Polypropylene pp twisted fiber for concrete is a high-performance macro fiber,mainly used in construction engineering.It is developed for replacement of steel fiber,with polypropylene as its raw material.It is produced by special drawing twsiting and surface treatment.Polypropylene PP twisted fiber compared with steel fiber,it can resist acid&alkail corrosion and are suitable for various structural concrete.

Contact Now

Polypropylene Twisted Bundle Fibers 38mm 54mm LengthThe polypropylene twisted bundle fibers are widely used with the continuous development of construction engineering .The polypropylene twisted bundle fiber is made of polypropylene as the main raw material through special parallel drawing and twisted molding process and surface treatment. Alternatives developed for steel fibers.Twisted bundle pp fiber is a material between steel fiber and synthetic fiber.

Contact Now

Product Details With polypropylene fiber as its raw cloth, curved pp macro fiber is produced with the aid of special molding technique and floor modification; it has gain of acid, alkali resistant, exceptional tensile, easy dispersing, convenience for construction and no damage to automobiles and pavement and no need for unique conservation. Curved pp macro fiber can be used rather than steel fiber to beautify the crack resistance of cement concrete and substantially enhance the longevity and flexural of concrete.

Contact Now