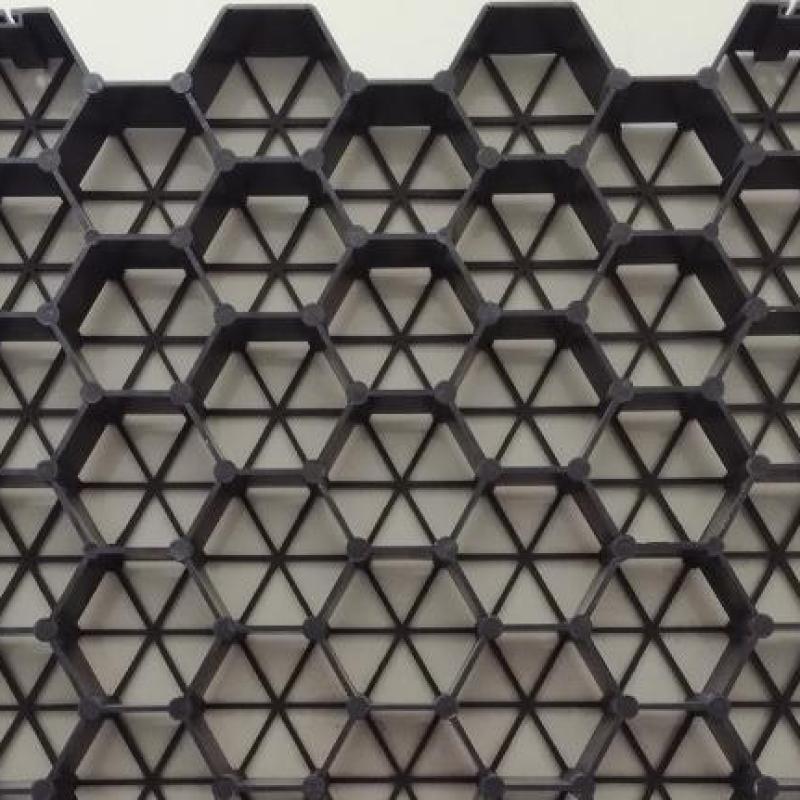

Product Details Factory Low price Driveway Road Slope Protection HDPE Paving Plastic Gravel Stabilizer Geocell Manufacturer For SaleHdpe geocell is crafted from a today's shape of high electricity geosynthetic, that's famous with each home and abroad, in accordance with gb/t 19274-2003 implementation of the necessities, which welding the bolstered hdpe sheets thru way of the excessive-strength ultrasonic and forming to be a shape of thr

Contact Now

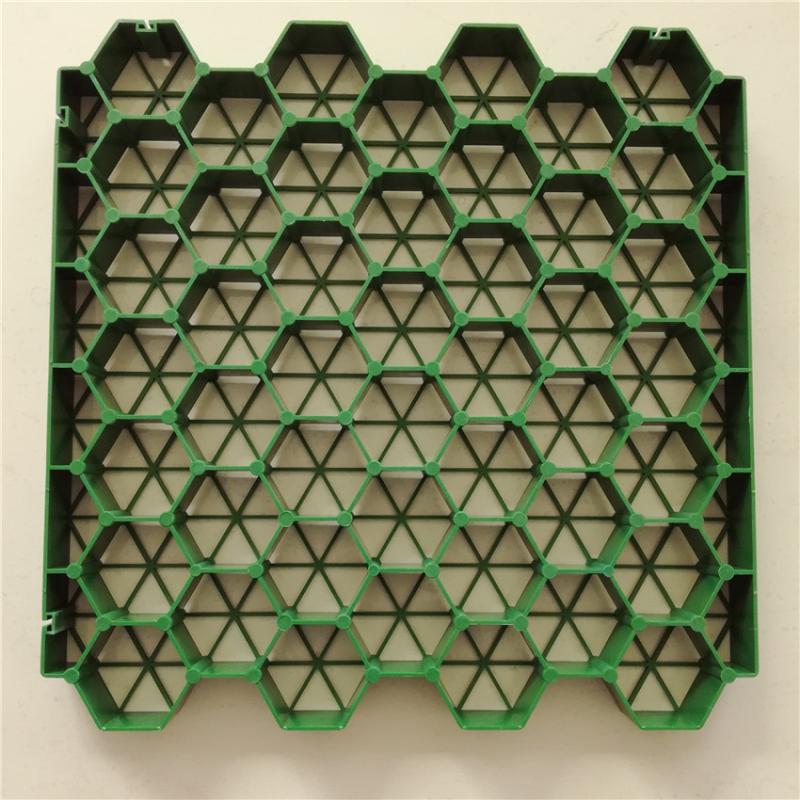

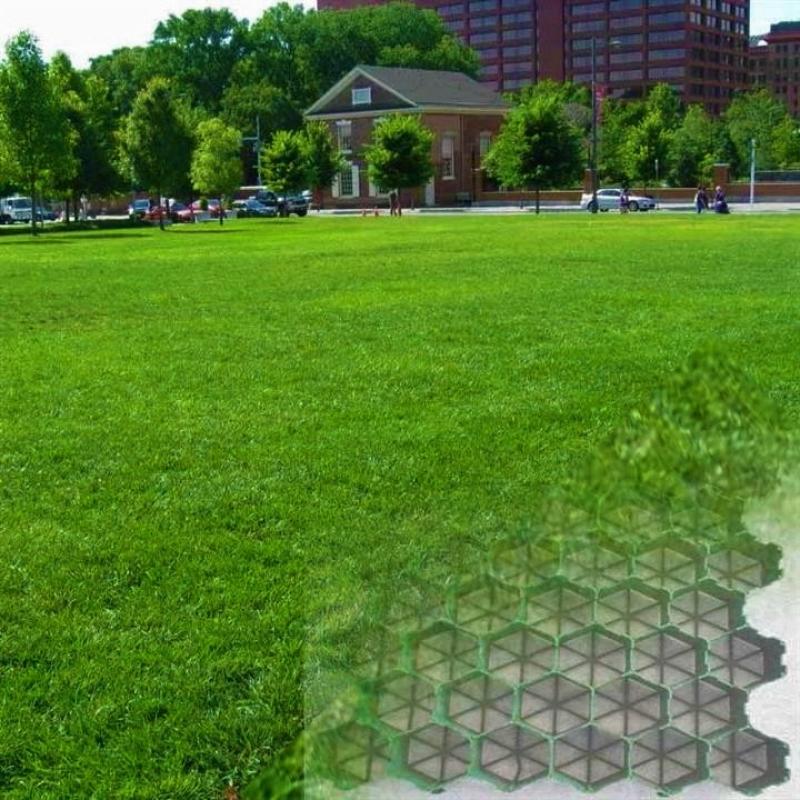

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contact Now

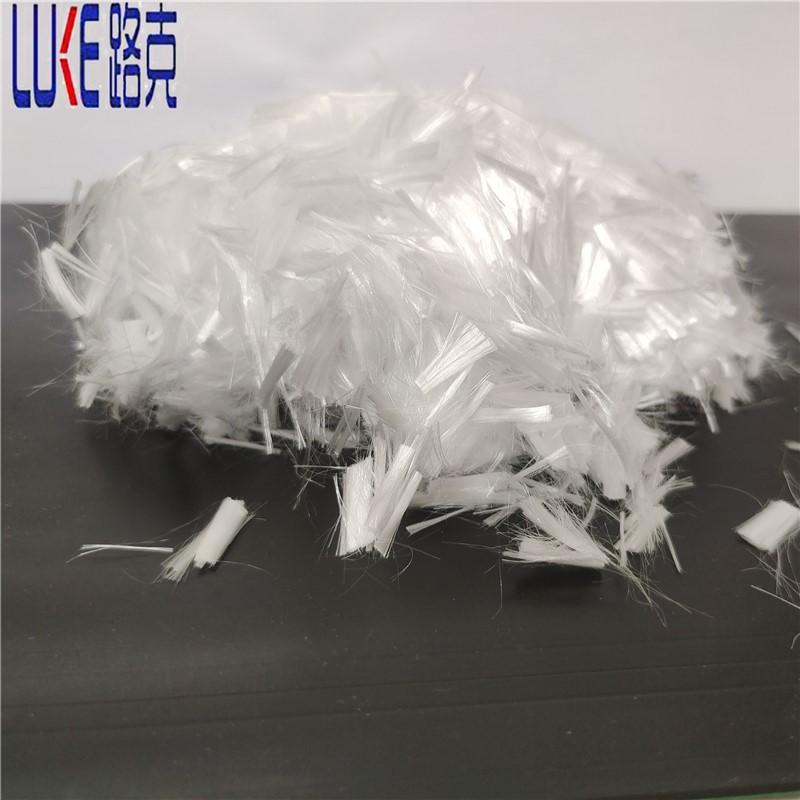

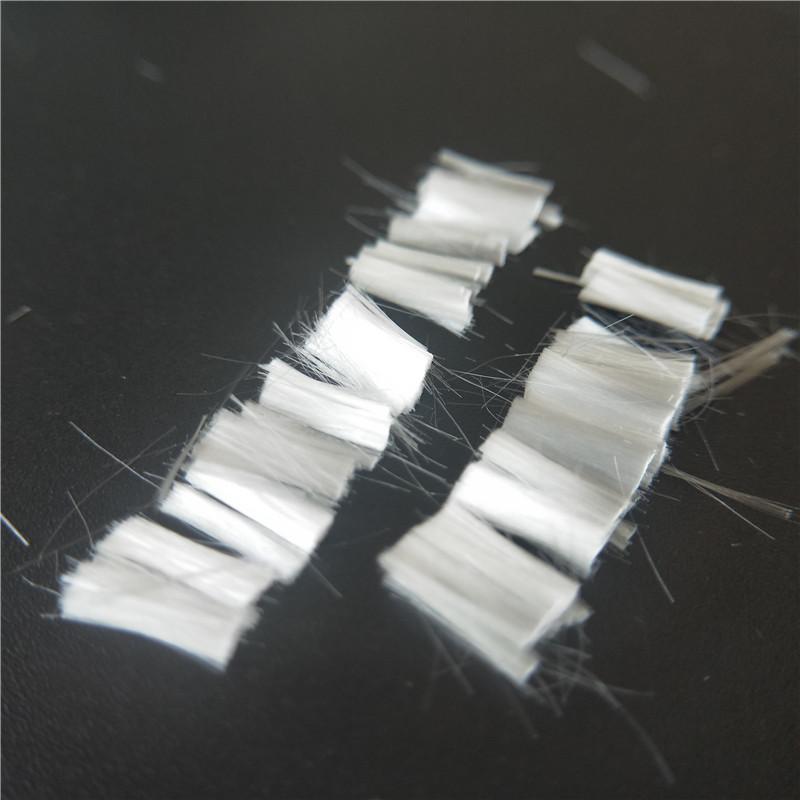

Polypropylene Short Cut Micro Fiber Reinforced FiberPolypropylene short cut pp micro fiber is one of the most commonly used polypropylene fiber. Polypropylene short cut micro fiber is a reinforced polypropylene fiber .Polypropylene micro pp fiber is a material used to enhance the performance of concrete, these polypropylene fibers can be evenly dispersed in the concrete to improve the physical properties and chemical stability of concrete. Its length is generally between 1-15mm.

Contact Now

Product Details As a new type concrete-strengthening fiber, it becomes a new popular subject in the field of fiber concrete application after glass fiber and steel fiber. Reinforced Functions to Concrete: compared with steel fiber, full-dispersed polypropylene fiber has advantages in its thinness, large amount, non-water absorbency, strong acid & alkali resistance and similar elastic modulus with that of concrete.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)

Contact Now

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contact Now

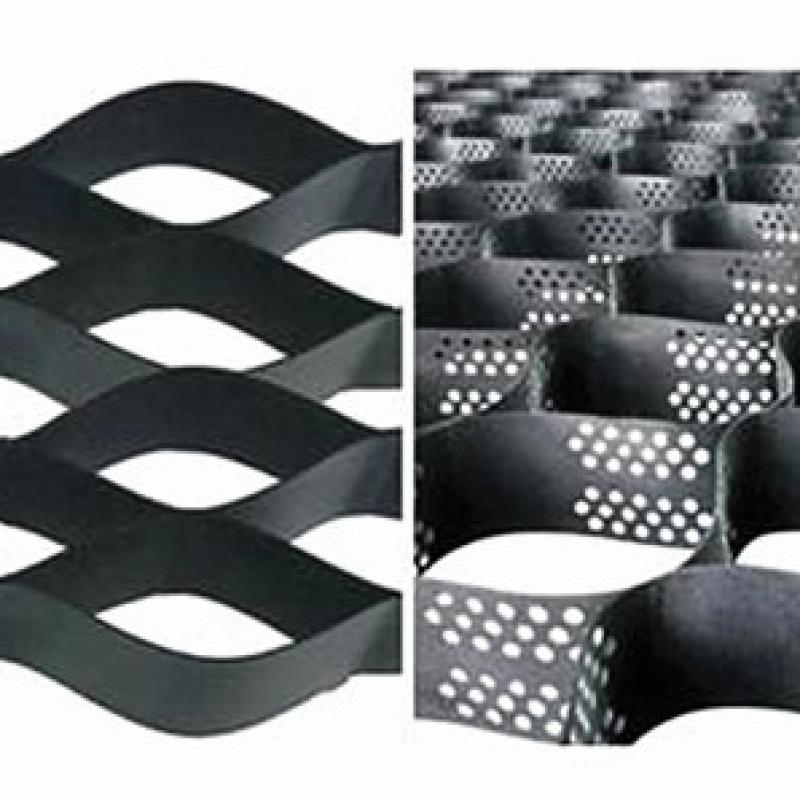

Polypropylene Synthetic Fiber for Shotcrete(wave shape Polypropylene Macro Fiber for Concrete)Polypropylene Synthetic Macrofiber for Concrete, like Shotcrete, replace steel fiber.It has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

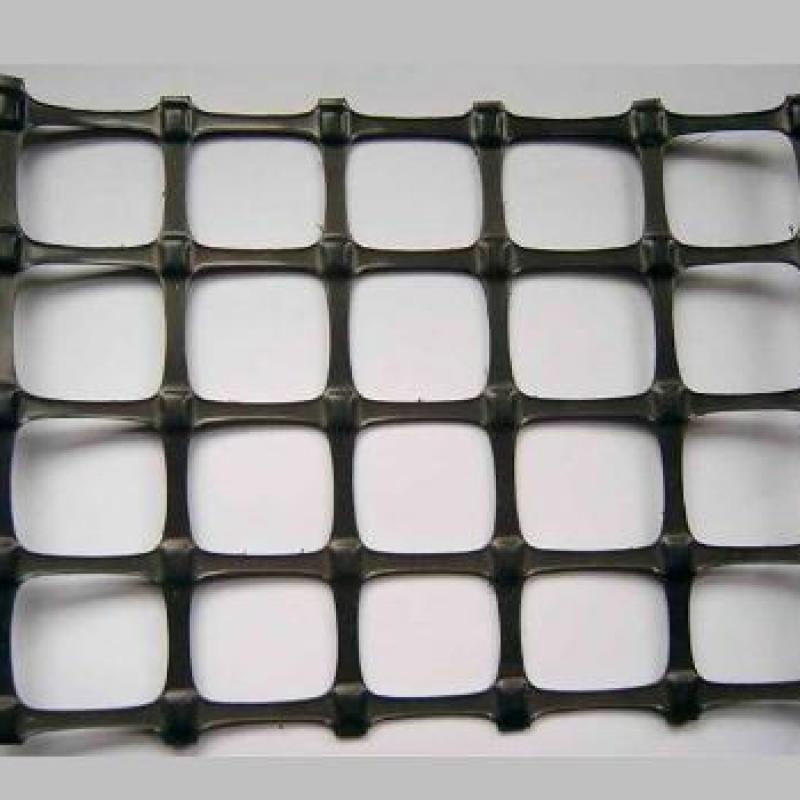

Product DetailsComposite drainage net is made from geonet bonding two layers of geotextile which combines the properties of geotextile filtration and geonet drainage and protection,providing complete“inverted filter drainage to protect”effect.Drainage nets core is extruded by high density polyethylene raw materials adding carbon black and ultraviolet and antioxidant stabilizer.The interlaced net forms into a drainage channel which has good vertical drainage properties.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic ConductivityM/SK*10

Contact Now

Product Details Within the concrete aggregate, upload right amount metallic fiber can be mixed into a sort of unique jetting in addition to casting concrete, particularly metal fiber bolstered concrete. As compared with popular concrete, metallic fiber concrete has superb improvement in tensile strength, flexural power, abrasion resistance, effect resistance, fatigue resistance, durability, crack resistance and antiknock performance, due to the fact big wide kind of very minute metal fiber is frivolously dispersed within the concrete and has a huge contact vicinity with concrete, co

Contact Now

Top Selling Polypropylene Micro Fiber For ConcretePP micro fiber(pp monofilament fiber) concrete fiber is our top selling production.It is a reinforcement polypropylene fiber.It is a polypropylene as the main raw material,adopting unique manufacturing process to make high strength white bundle monofilament fiber.Join concrete or mortar can effectively control concrete or mortar microcracks which is caused by plastic shrinkage,temperature changes and other factors,to prevent and inhibit the formation and development of cracks,greatly improved crack resistance of concrete,impact resistance and s

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now