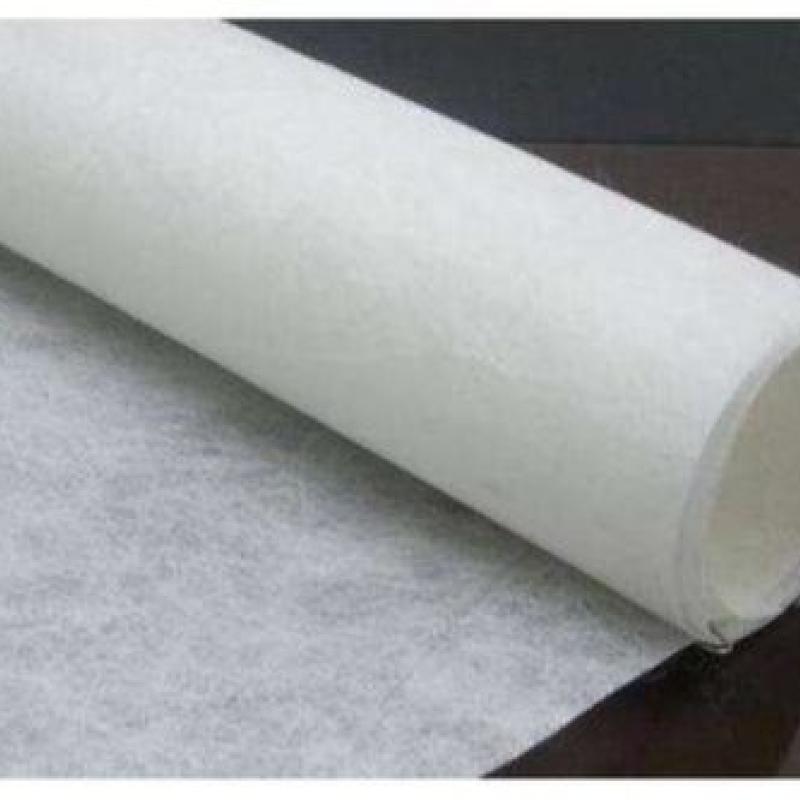

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure. It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging. The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21

Contact Now

Product Details The filament non-woven geotextile is made from polyester lengthy fiber forming into net and consolidation with three size shape. It is a type of new fabric in geotechnical and engineering task.Except for its precise mechanical residences of tensile energy and puncture resistance,it additionally had excellent drainage capability,acid and alkali resistance and anti-getting older.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.25.5Width Variation%-0.5Break StrengthKN/m4.57.510.512.515

Contact Now

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging.The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.2

Contact Now

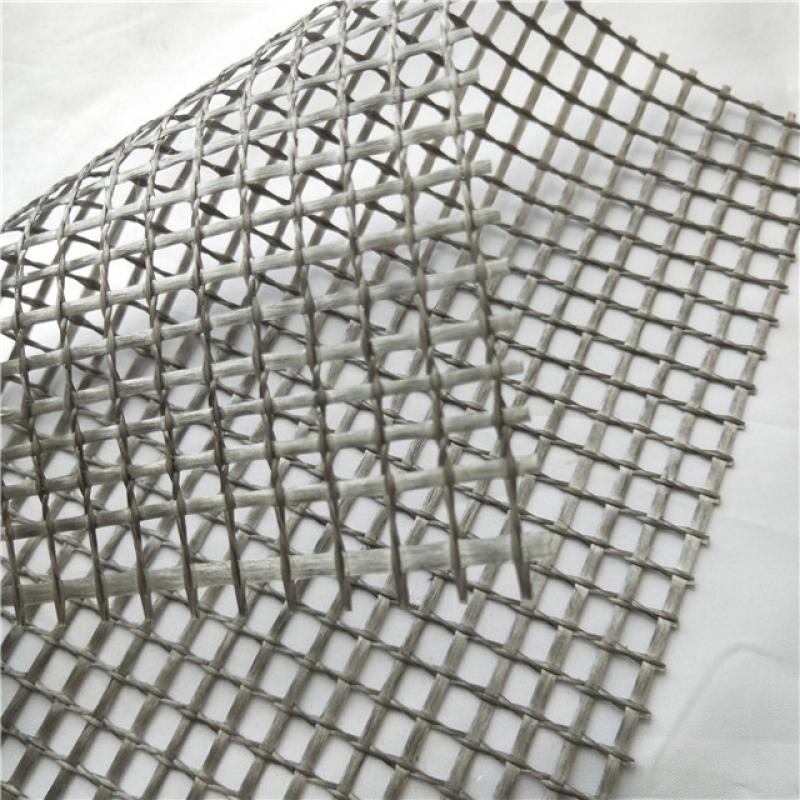

Product Details The Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges. In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contact Now

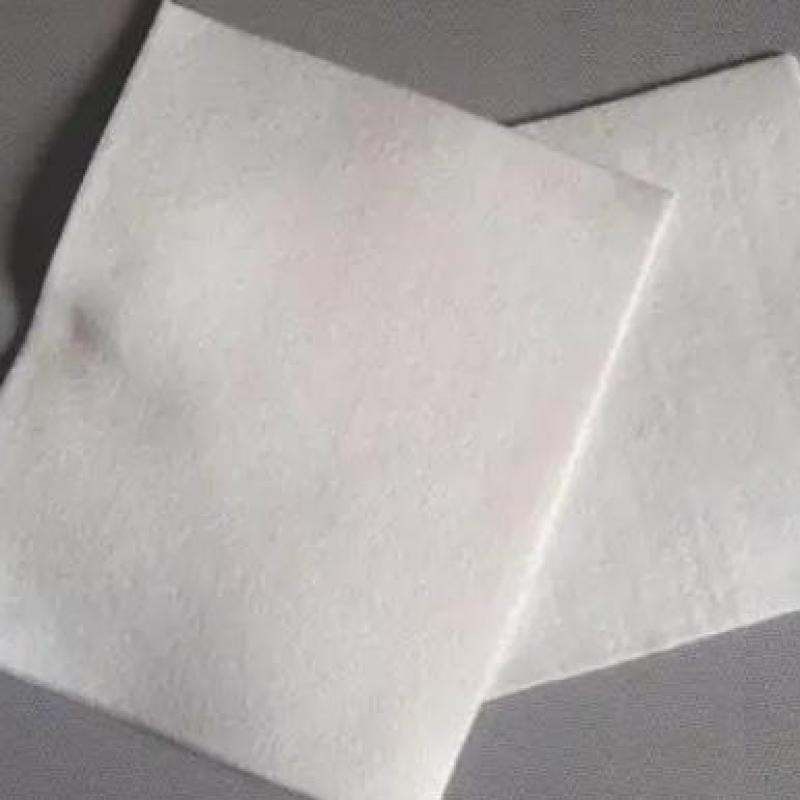

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness. Geotextiles play an important and crucial role in the civil engineering works. The wide spectrum of geotextiles and related products that are available to civil engineers to solve a wide range of problems along with their functions and possible applications. Geotextiles are permeable textile structures made of polymeric materials and are used mainly in civil engineering applications in conju

Contact Now

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For ConcreteFiberglass mesh is fiberglass leno cloth because the substrate, the anti-emulsion polymer coating after immersion, which has appropriate Alkali resistance, flexibility and robust tensile energy, it is able to be extensively utilized in exterior insulation finishing system (eifs), roofing System, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant fiberglass fabri

Contact Now

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging.The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.2

Contact Now

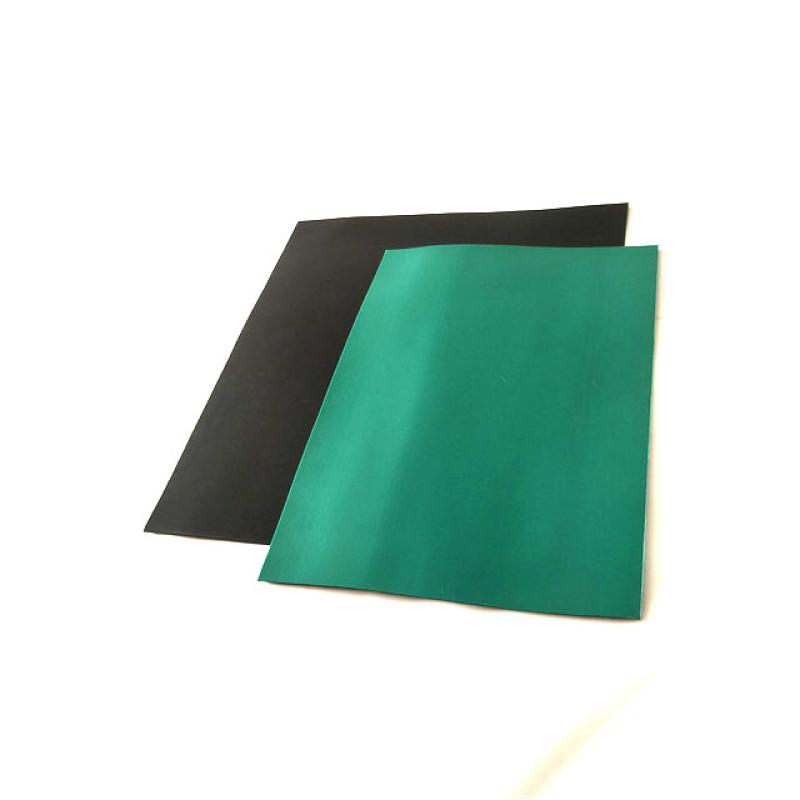

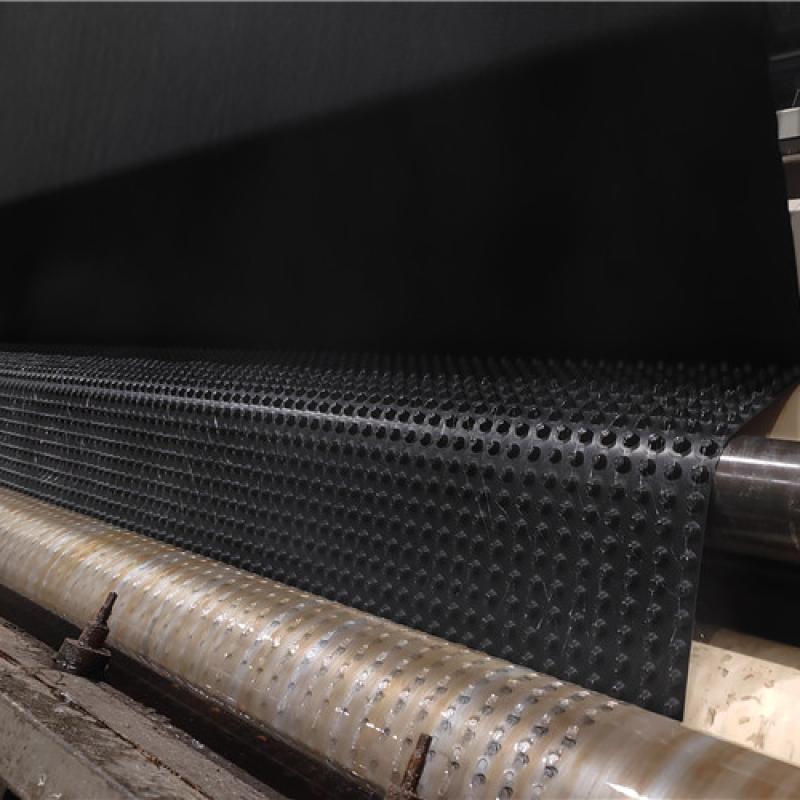

Product DetailsComposite Geomembrane Liner is made by heat-bonding nonwoven or woven geotextile to HDPE geomembranes by calendaring processing technology.The composite geomembrane liner has the functions and advantages of both geotextiles and geomembranes.The geotextile layer increases essential tensile strength and the geomembranes provides excellent impermeable, leak and moisture proof.They are widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc.FeatureHigh tensile strength and tearing strengthExcellent seepage control, seepage pr

Contact Now

Product detailsComposite geomembrane liner is made by heat-bonding nonwoven or woven geotextile to hdpe geomembranes by using calendaring processing era.The composite geomembrane liner has the functions and benefits of both geotextiles and geomembranes.The geotextile layer will increase essential tensile electricity and the geomembranes offers tremendous impermeable, leak and moisture evidence.They are broadly used for landfills, waste water remedy, roads production, aquaculture, landscape and agriculture, and many others.FeatureHigh tensile strength and tearing strengthExcellent seepage contr

Contact Now

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness. Geotextiles play an important and crucial role in the civil engineering works. The wide spectrum of geotextiles and related products that are available to civil engineers to solve a wide range of problems along with their functions and possible applications. Geotextiles are permeable textile structures made of polymeric materials and are used mainly in civil engineering applications in conjuncti

Contact Now