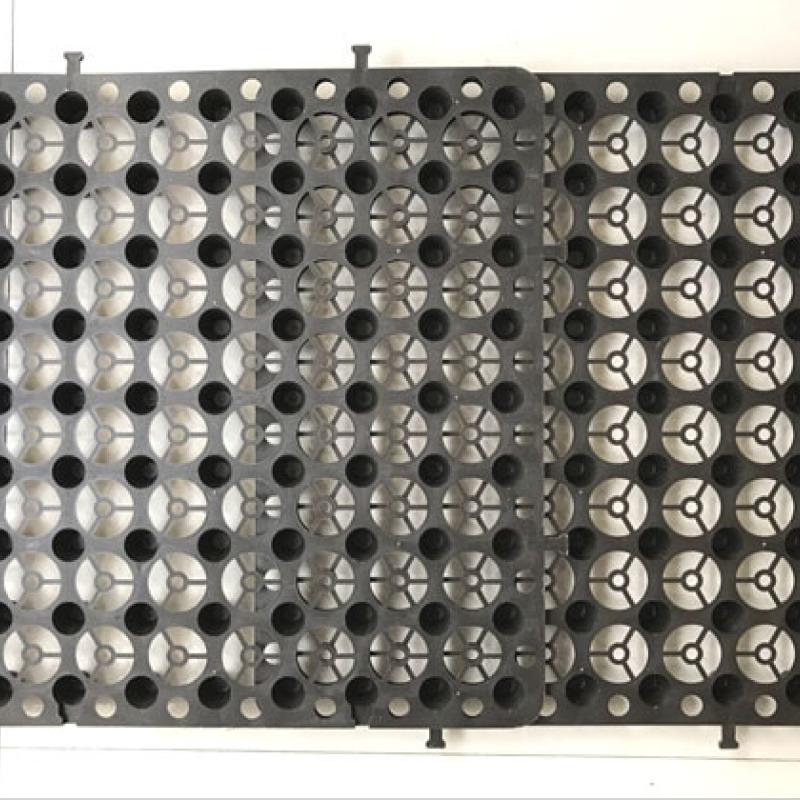

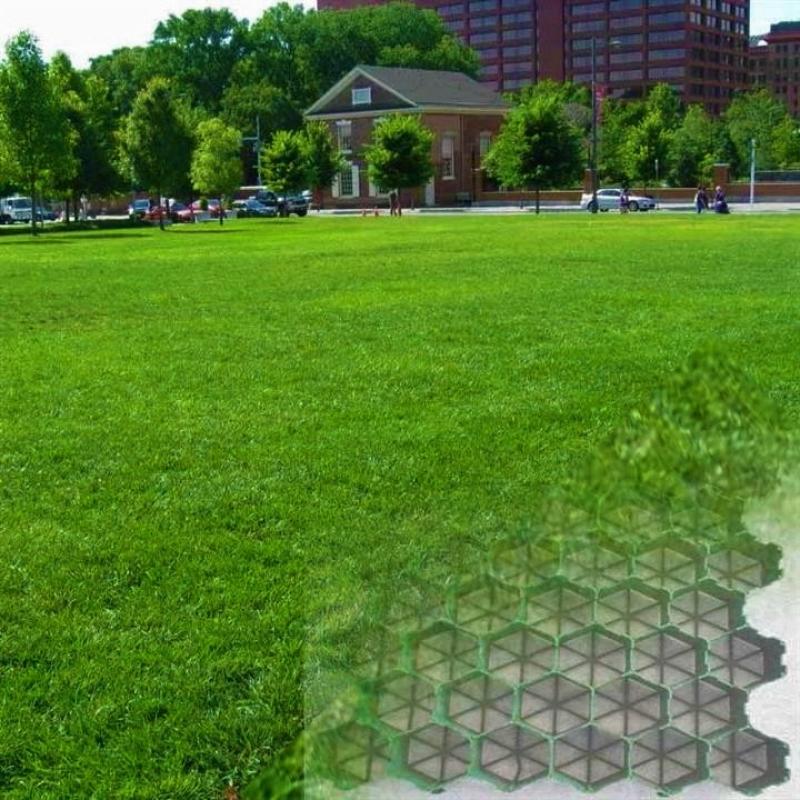

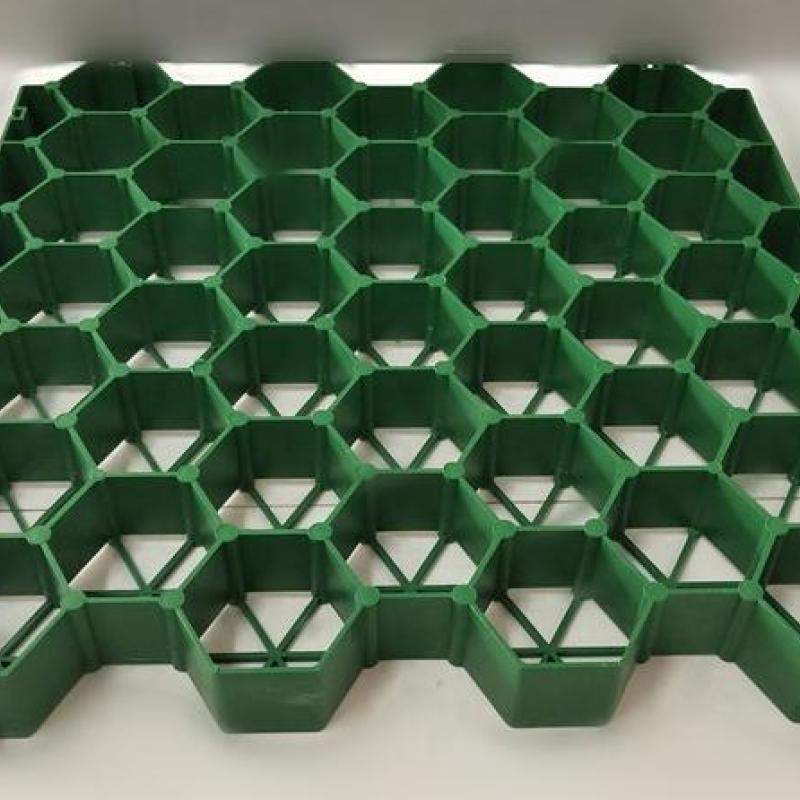

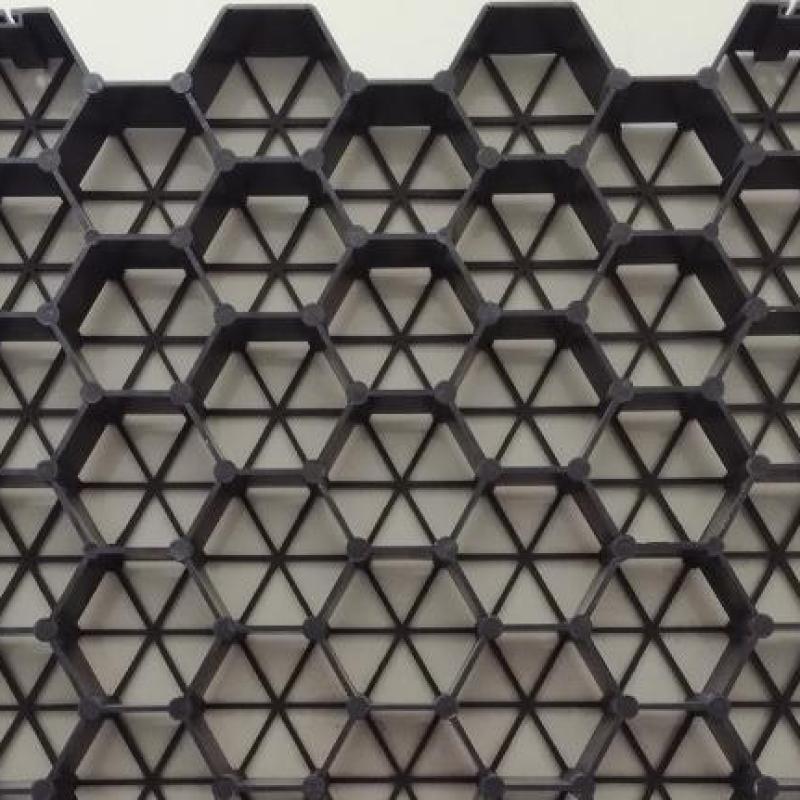

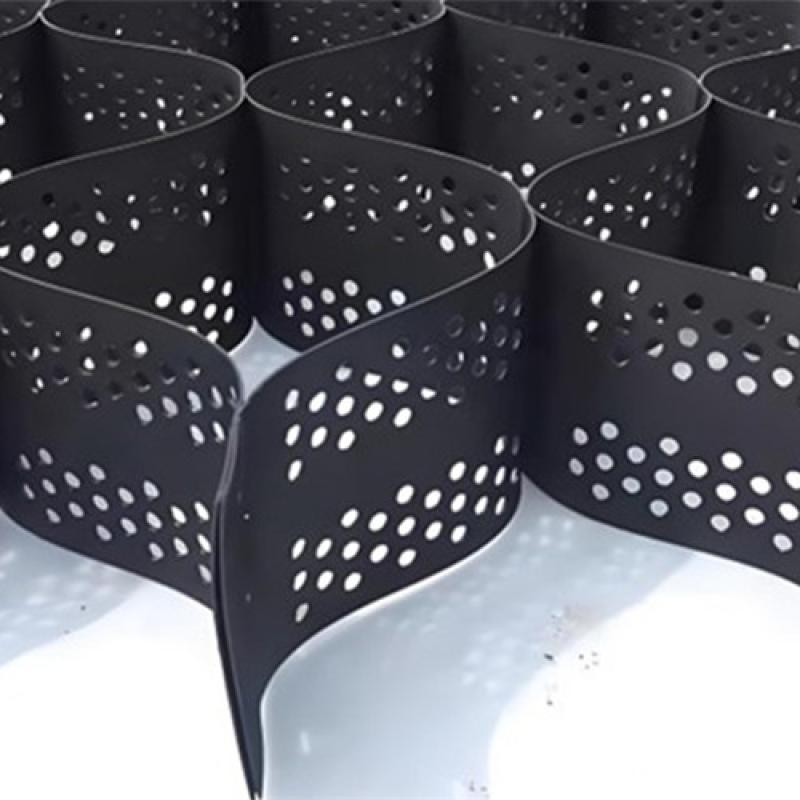

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contact Now

Product DetailsHdpe geocell is made of a brand new kind of high energy geosynthetic, that is famous with each domestic and overseas, in accordance with gb/t 19274-2003 implementation of the standards, which welding the bolstered hdpe sheets by means of the high-energy ultrasonic and forming to be a shape of 3-dimensional reticular formation that is without problems folding and handy for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,con

Contact Now

The geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site.

Contact Now

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contact Now

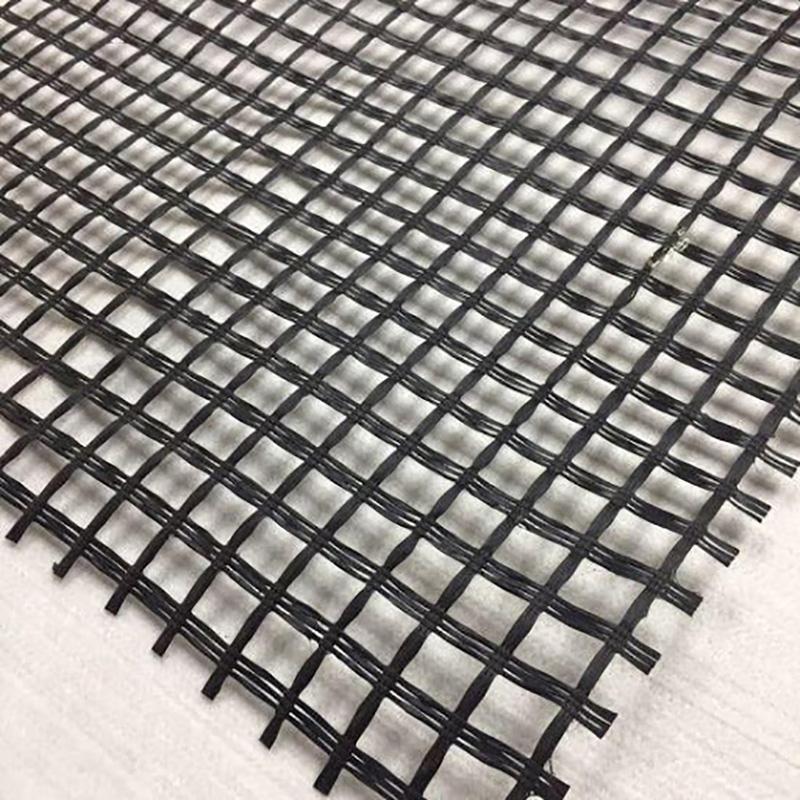

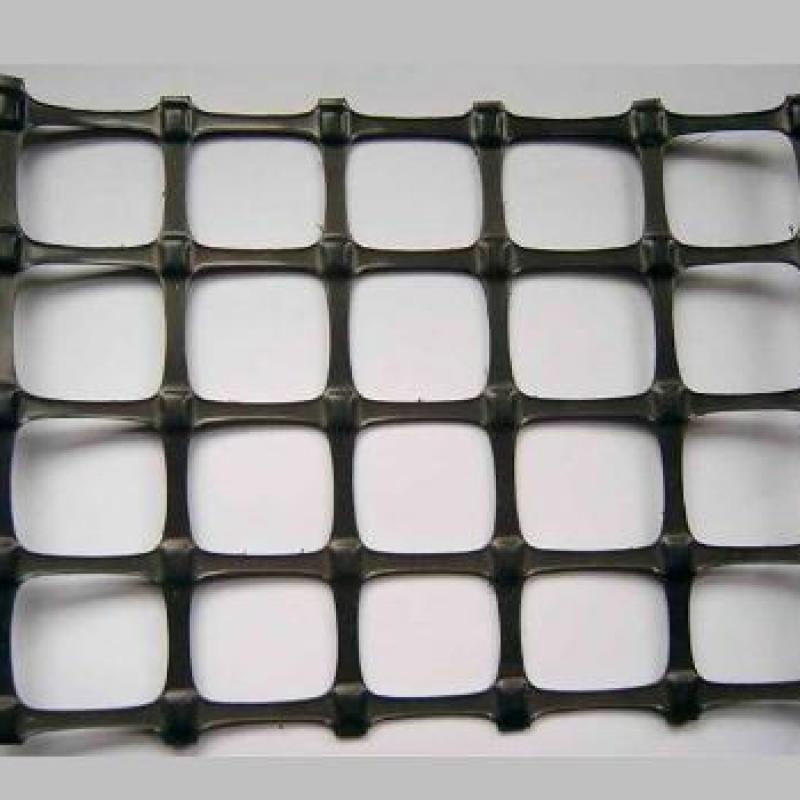

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Contact Now

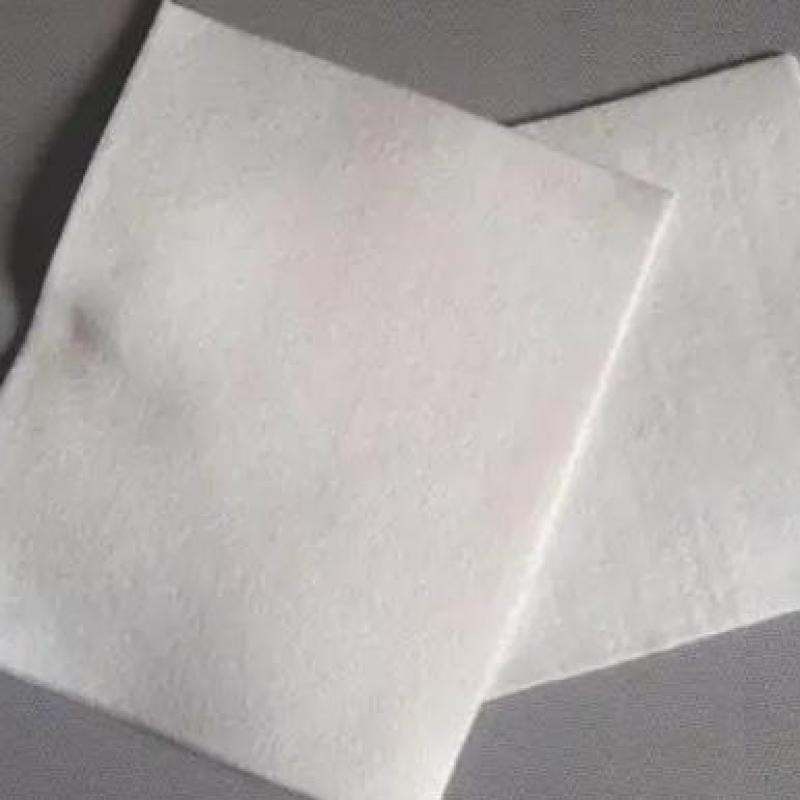

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now

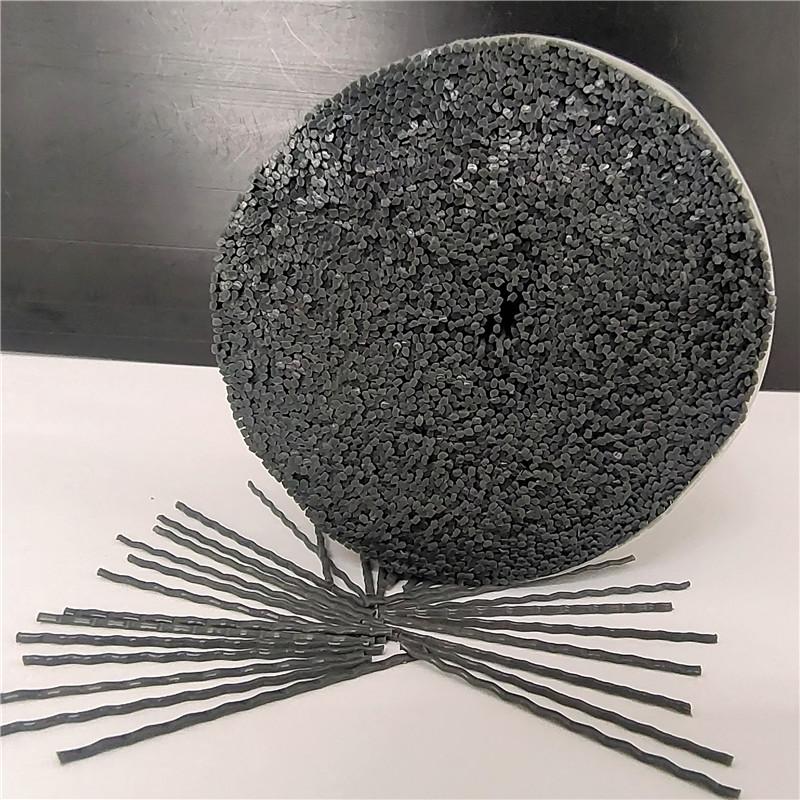

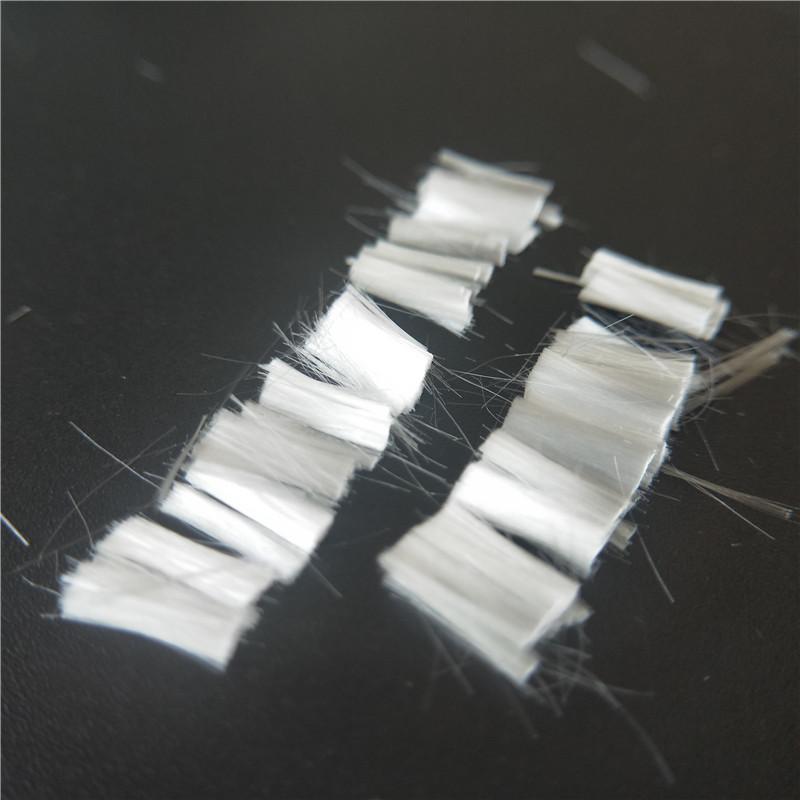

PP Macro Reinforced Fiber Concrete FiberPP macro reinforced fiber concrete fiber is a special type of concrete material dedicated to concrete/mortar high-performance fiber, which can effectively control the concrete/mortar plastic shrinkage, dry shrinkage, temperature change and other factors caused by micro cracks, prevent and inhibit the formation and development of concrete primary cracks, greatly improve the concrete/mortar crack resistance, anti-seepage performance, impact wear performance, increase the toughness of concrete.

Contact Now

Twisted Polypropylene Fiber for Concrete ReinforcementWhat is polypropylene fiber? Concrete PP Fiber Twisted Bundle is developed for replacement of steel fiber, with polypropylene as its raw material,polypropylene twisted bundle PP fiber is produced by special drawing,twisting and surface treatment. Compared with steel fiber,it has advantages of acid,alkali resistant,excellent tensile,easy dispersing, convenience for construction and no damage to the mixing equipment.What is the action principle of polypropylene fiber ? When the pp fiber is put into th

Contact Now

Product detailsWe verify : a hundred% virgin hdpe + 2~3% carbon black + antioxidant, anti-growing old and uv resistance aspect.We supply : advanced equipment + 24 hours manufacturing + take a look at every roll+ popular exporting bundle.We endorse : zero.5 mm or zero.seventy five mm-thickness is used for pond liner1.5 mm-thickness is used for landfill2.zero mm-thickness is used for dam liner.Parameter Test PropertiesunitTest Method Test FrequencyLKMS75LKMS10LKMS15LKMS20LKMS30 Mechanical Properties ThicknessmmD5199Per roll0.751.001.502.003.00&nb

Contact Now

Product DetailsDimple drain board is using basis or blow molding approach to provide excessive density polyethylene (hdpe) geomembrane, pressed on geomembrane pressure after the special craft the closed swelled the frustum of a cone shape, having a 3-dimensional space and a few help stiffness, liquid, gasoline can glide excreted internal its plate.That could be a latent many functions substances, the usage of this plate may be without difficulty built out of the overhead layer, the use of overhead layer fashioned drainage, exhaust passage, at the equal time to apply the overhead layer reaches

Contact Now