Product DetailsThe Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges.In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contact Now

Product Details The Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges. In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contact Now

Product DetailsThe woven geotextile is produced via virgin polypropylene fiber ,is made of as a minimum two rows of parallel yarns(or tape yarn),the use of unique weaving machines and technologies to weave the warps and wefts into textile form with diverse thickness and compactness in keeping with utilization stages.In preferred,woven geotextile is with distinctly mild in weight,robust tensile energy,smaller elongation in addition to super balance. our polypropylene woven geotextile is fairly light in weight, robust tensile power, smaller elongation in addition to wonderful balance.

Contact Now

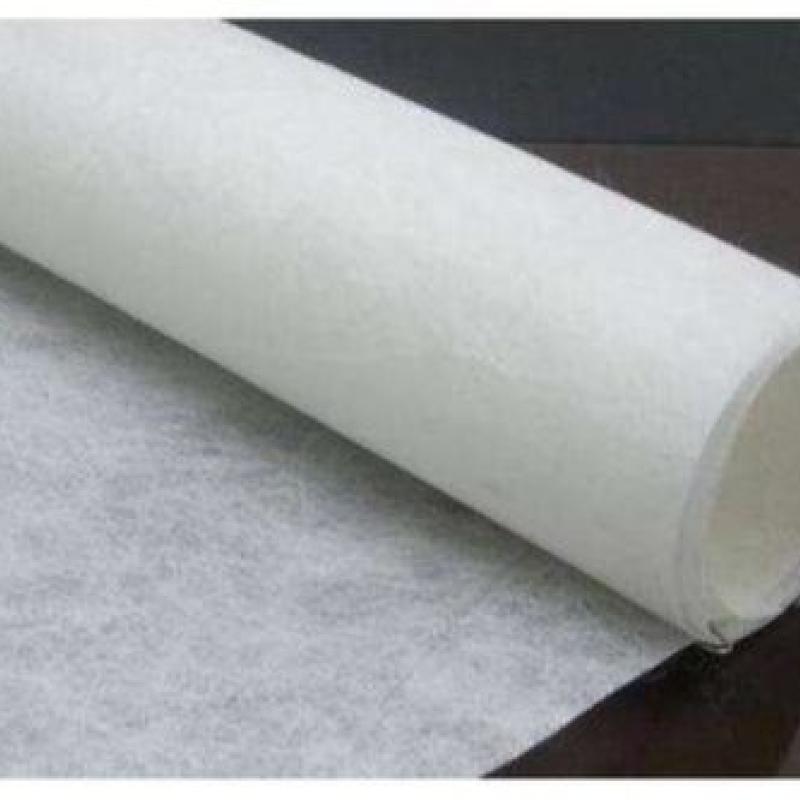

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

Product DetailsThe woven geotextile is produced by way of virgin polypropylene fiber ,is product of as a minimum two rows of parallel yarns(or tape yarn),the usage of one of a kind weaving machines and technology to weave the warps and wefts into textile shape with various thickness and compactness in keeping with usage degrees.In wellknown,woven geotextile is with enormously mild in weight,robust tensile electricity,smaller elongation in addition to outstanding stability.

Contact Now

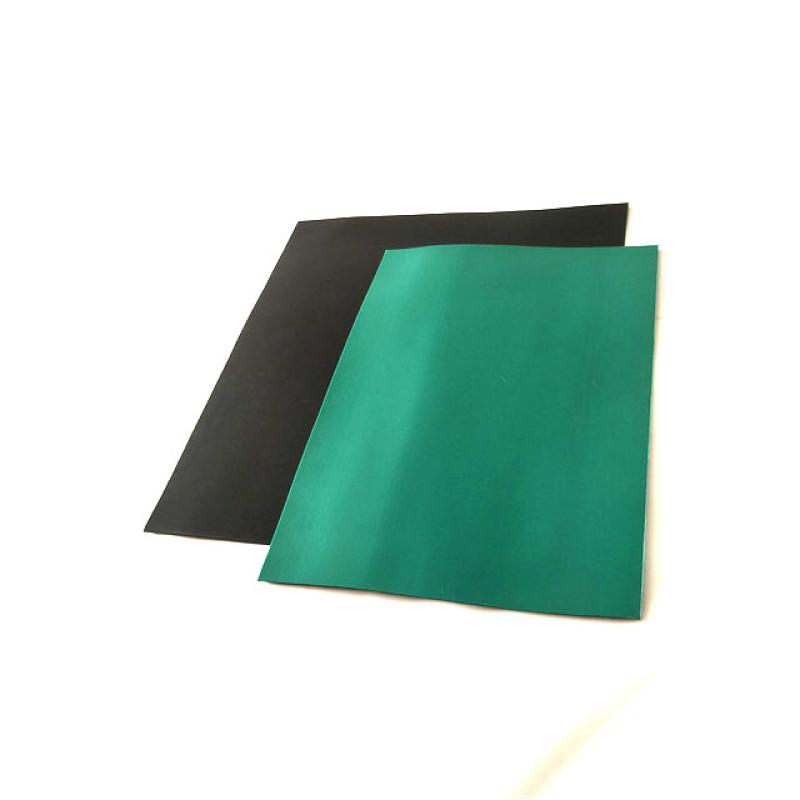

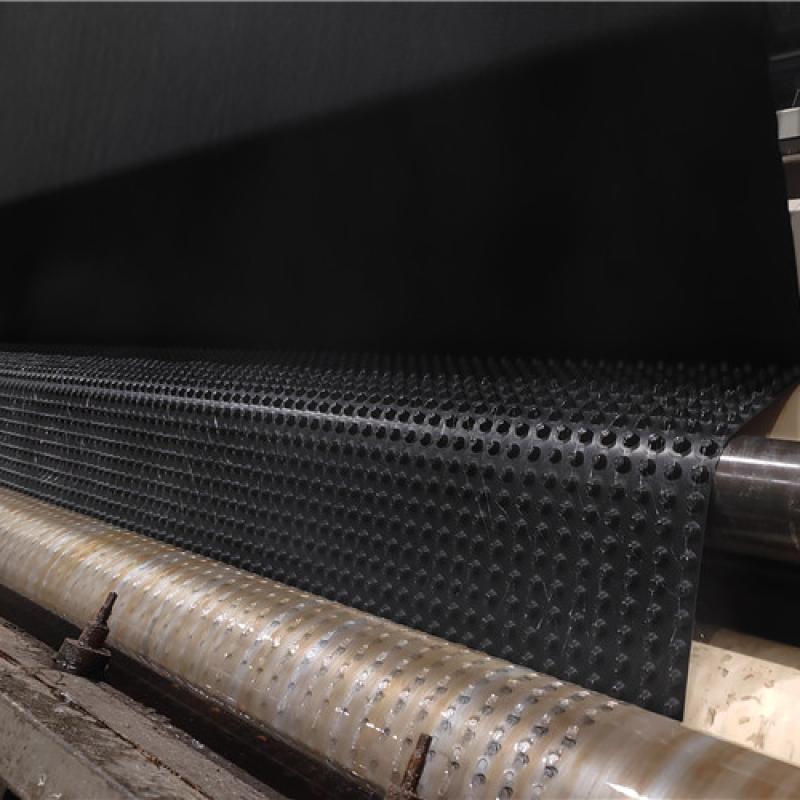

Product detailsComposite geomembrane liner is made by heat-bonding nonwoven or woven geotextile to hdpe geomembranes by using calendaring processing era.The composite geomembrane liner has the functions and benefits of both geotextiles and geomembranes.The geotextile layer will increase essential tensile electricity and the geomembranes offers tremendous impermeable, leak and moisture evidence.They are broadly used for landfills, waste water remedy, roads production, aquaculture, landscape and agriculture, and many others.FeatureHigh tensile strength and tearing strengthExcellent seepage contr

Contact Now

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness. Geotextiles play an important and crucial role in the civil engineering works. The wide spectrum of geotextiles and related products that are available to civil engineers to solve a wide range of problems along with their functions and possible applications. Geotextiles are permeable textile structures made of polymeric materials and are used mainly in civil engineering applications in conjuncti

Contact Now