Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

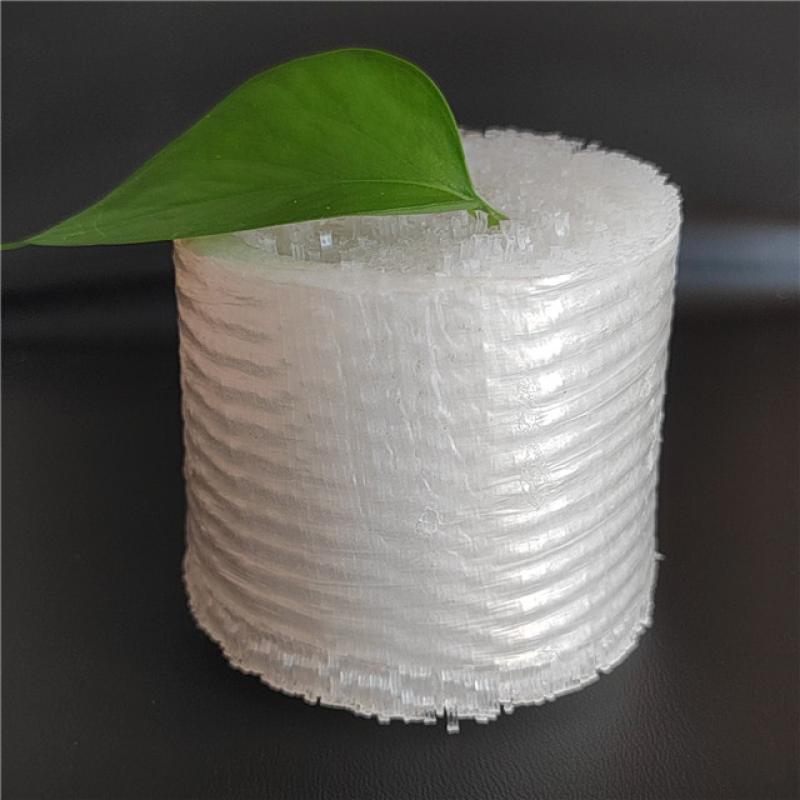

China Supplier Polypropylene Mesh Fiber for ConcreteProduct DetailsWhile the fiber is positioned into the concrete, the horizontal structure in fiber monofilament can be destroyed in the direction of stirring.As a result of friction and rubbing, and the fiber monofilament or internet-like form will absolutely stretch, therefore the concrete is strengthened via the usage of a brilliant amount of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Stre

Contact Now

High Tensile Strength Macro Steel Fibers for Concrete Reinforcement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely steel fiber reinforced concrete.

Contact Now

Product DetailsWhen it is be in construction,the hdpe geocell may be pull right into a community and launched into a three-dimensional honeycomb grid.As it crammed in sol,macadam,concrete or other granular materials,constituted to be a production which has robust sidewise restraint and excessive rate of stiffness.ParameterProduct TypeHeight (mm)Welding Distance (mm)Thickness (mm)Tensile Strength of Welding Points (N/cm)Tensile Strength of Commection of Cells (N/cm)Tensile Strength of Yield of Each Sheet (Mpa)Smooth and Not Perforated50MM≤H≤250330MM ≤A≤ 10001.0-1.421002120220Smooth an

Contact Now

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Contact Now

Product IntroductionHDPE Geomembrane Good mechanical properties, high tear strength,Deformation and adaptable, puncture resistance,Anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion,High temperature-resistant, non-toxic,long service life.Water,drainage, seepage, the good effect of moisture, low cost, easy construction.Parameter Test PropertiesunitTest Method Test FrequencyLKMS75LKMS10LKMS15LKMS20LKMS30 Mechanical Properties ThicknessmmD5199Per roll0.751.001.502.003.00 Densityg/ccD1505/D79290,000kg &nbs

Contact Now

Macro PP Fibers for Concrete ReinforcementWith 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now