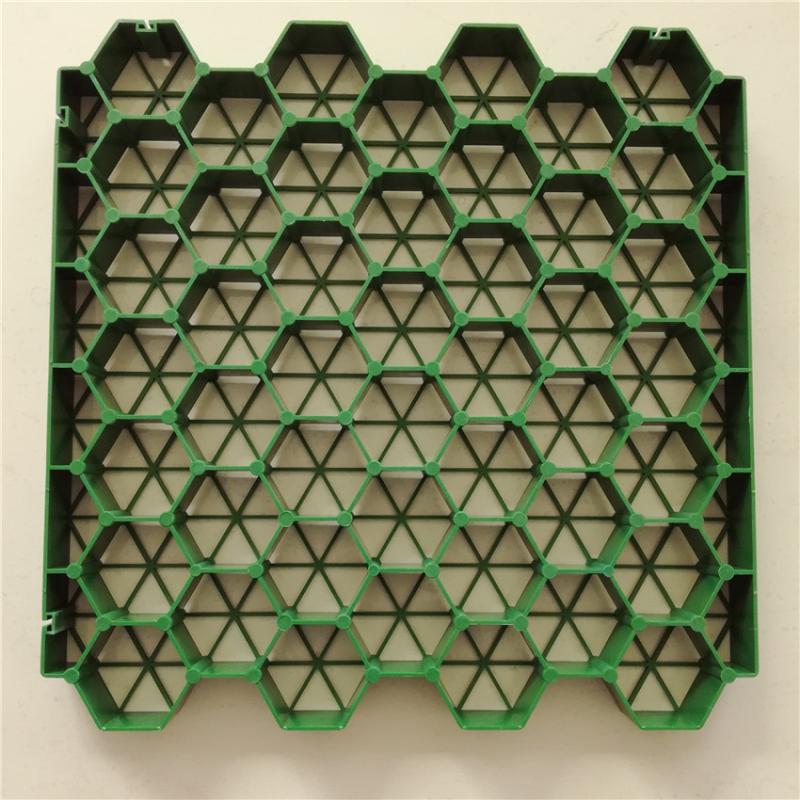

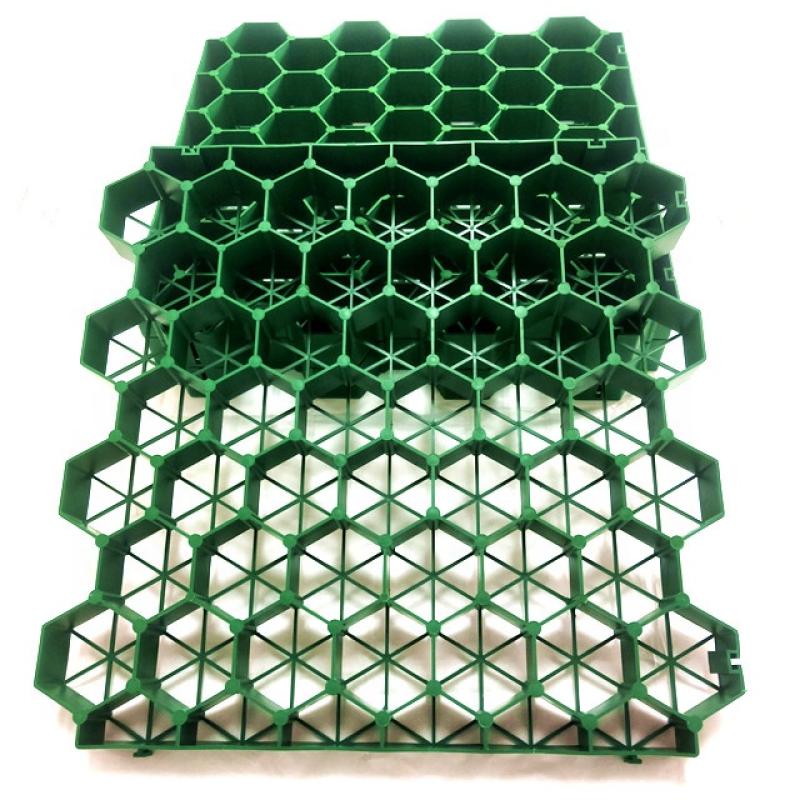

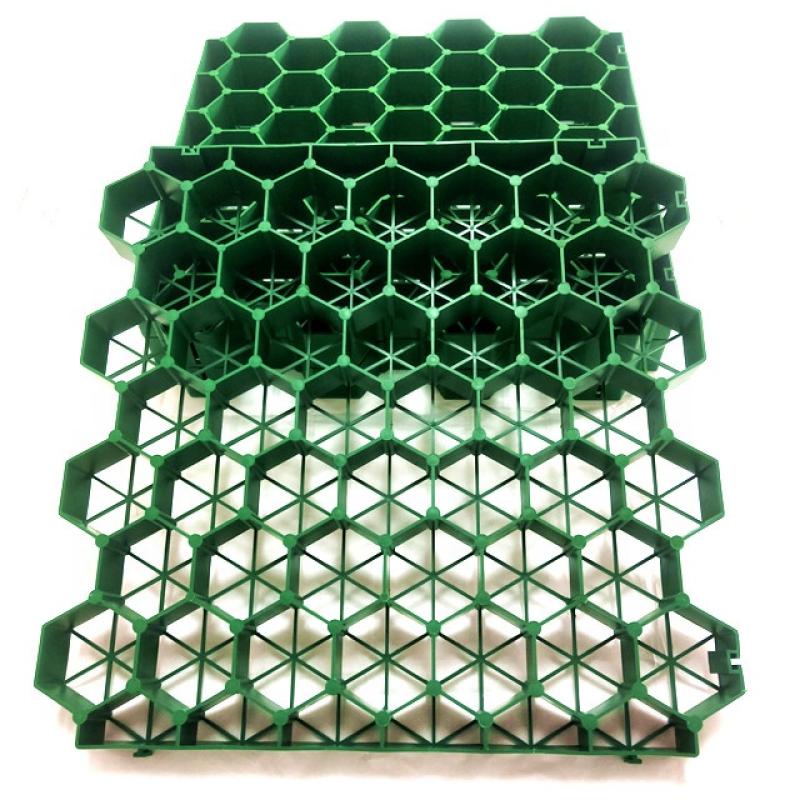

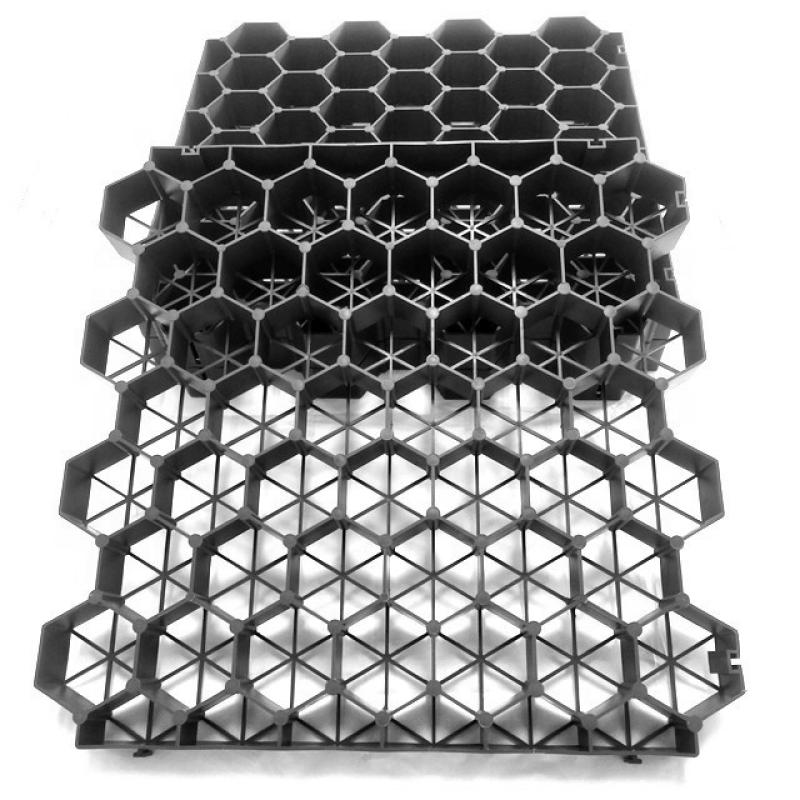

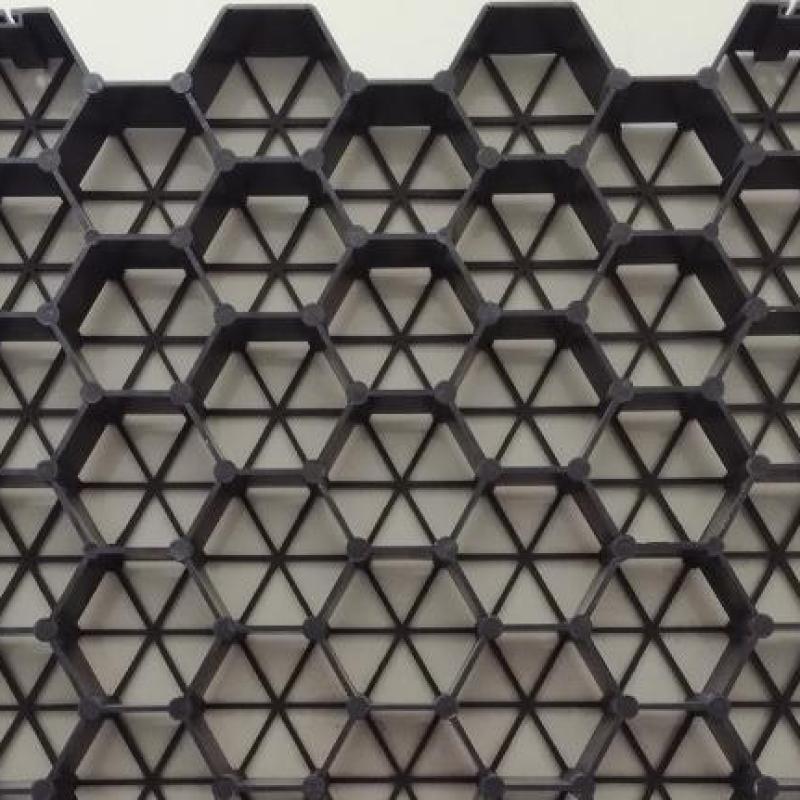

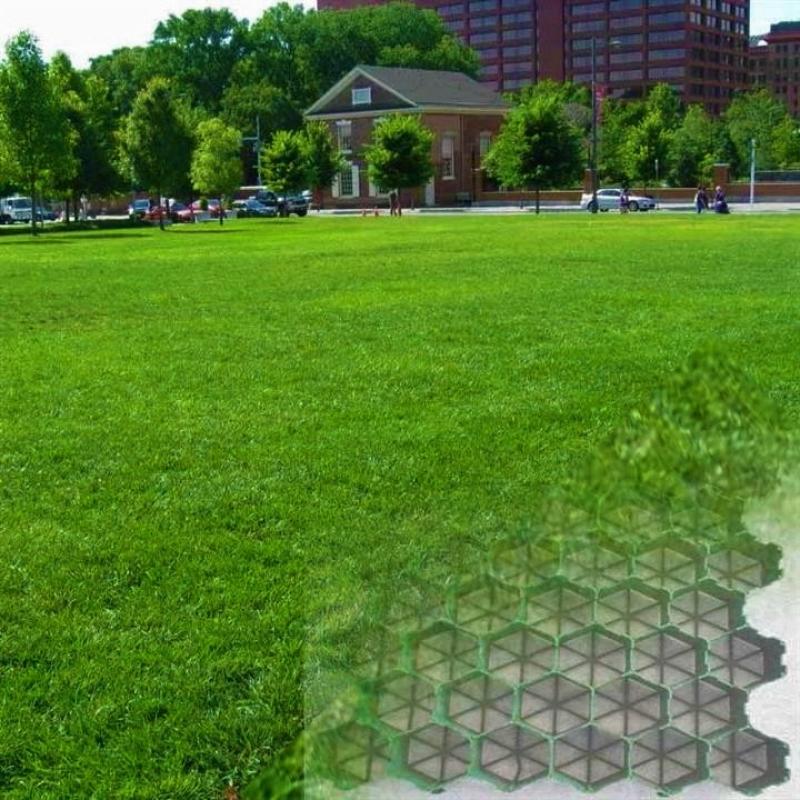

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contact Now

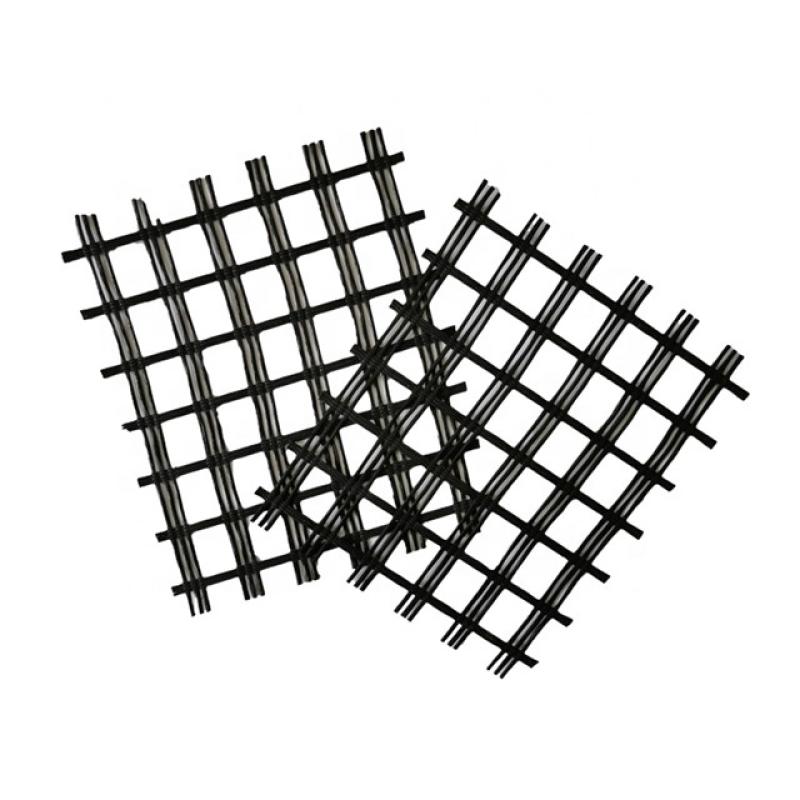

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

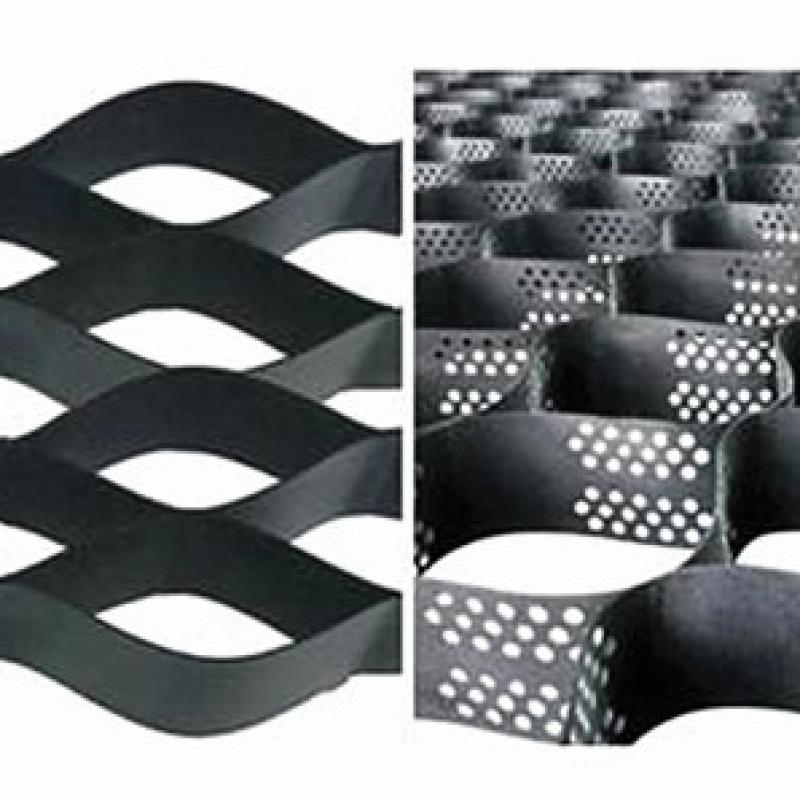

Product Details Factory Low price Driveway Road Slope Protection HDPE Paving Plastic Gravel Stabilizer Geocell Manufacturer For SaleHdpe geocell is crafted from a today's shape of high electricity geosynthetic, that's famous with each home and abroad, in accordance with gb/t 19274-2003 implementation of the necessities, which welding the bolstered hdpe sheets thru way of the excessive-strength ultrasonic and forming to be a shape of thr

Contact Now

Product Details HDPE Geocell for Road Construction Reinforcement HDPE Geocell is made from a contemporary form of high energy geosynthetic, that is famous with each domestic and distant places, in accordance with Gb/t 19274-2003 implementation of the requirements, which welding the strengthened hdpe sheets with the aid of the excessive-strength ultrasonic and forming. To be a form of 3-dimensional

Contact Now

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Contact Now

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Contact Now

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

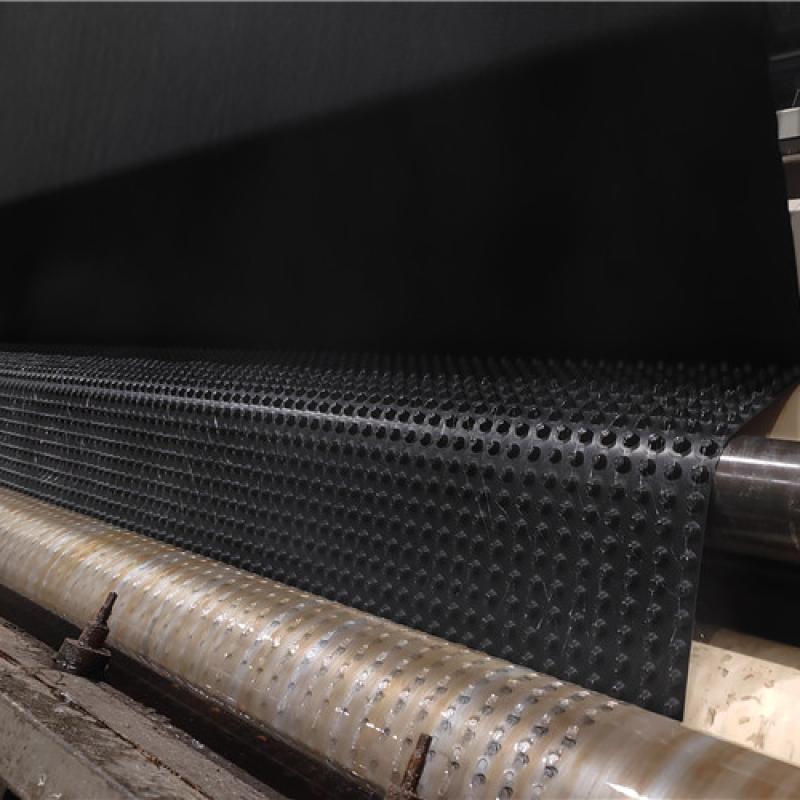

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now