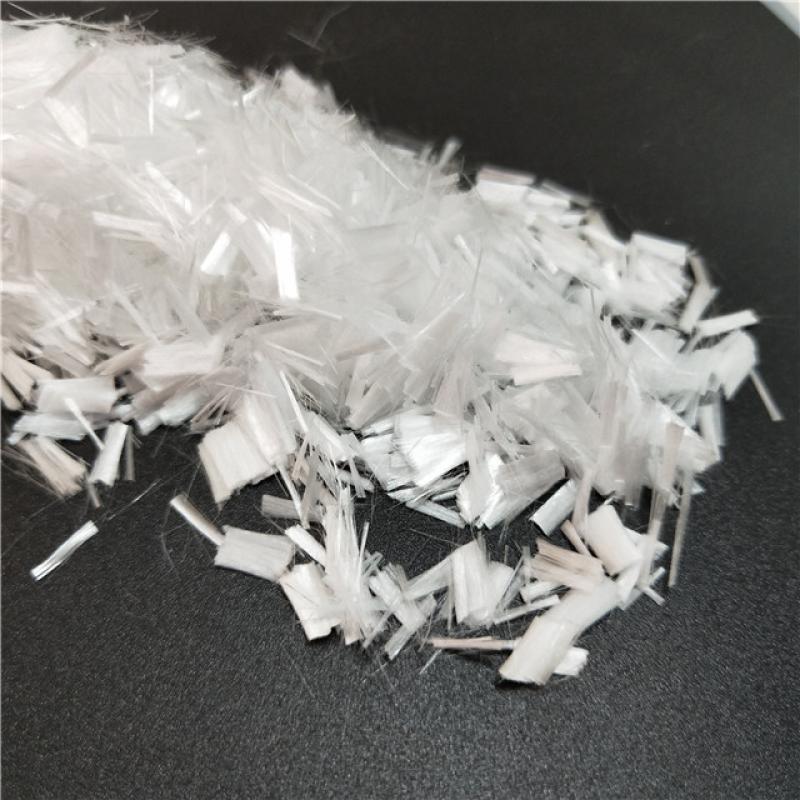

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Contact Now

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Contact Now

Polypropylene Twisted Bundle Fiber Reinforced ConcretePolypropylene twisted bundle fiber reinforced concrete is widely used in concrete engineering.Bundle twisted PP fiber is developed for replacement of steel fiber.It has more advantages in concrete structures,except the characteristics of ordinary steel fiber.With polypropylene as its raw material,it is producted by special drawing twisting and surface treatment.It has good acid and alkail resistance.Twisted bundle pp fiber has high strength,Polypropylene twisted bundle fiber has very good corrosion resistance and anti-aging ability.Excellen

Contact Now

China Manufacturer Polypropylene Twist Bundle Fiber for Concrete Reinforcement What is the action principle of polypropylene fiber ?

Contact Now

Product Details PP Twist Bundle Fiber Twisted Bundle PP Fiber is developed for replacement of steel fiber. With polypropylene as its raw material,it is produced by special drawing twisting and surface treatment.

Contact Now

Product Details Twisted package pp fiber is evolved for replacement of metallic fiber. With polypropylene as its uncooked fabric,it is produced via special drawing twisting and floor remedy. In comparison with metal fiber, it has advantages of acid, alkali resistant, terrific tensile, easy dispersing, convenience for creation and no damage to the integration device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwist

Contact Now

Product Details Twisted Bundle PP Fiber is developed for replacement of steel fiber. With polypropylene as its raw material,it is produced by special drawing twisting and surface treatment. Compared with steel fiber, it has advantages of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction . ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwist or HybridMelting Point160-170 ℃ &n

Contact Now

China Manufacturer Polypropylene Twist Bundle Fiber for Concrete Reinforcement What is the action principle of polypropylene fiber ? When the pp fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing, and the fiber monofilament or net- like structure will fully stretch, thus the concrete is reinforced by a great number of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/Grey

Contact Now

Concrete PP fiber is a polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle mono-filament fiber.

Contact Now

Product DetailsTwist Bundle PP Fiber Bunchy Form Concrete Polypropylene Fibers Twisted package deal pp fiber Bunchy Form Concrete Polypropylene Fibers is superior for replacement of steel fiber. with polypropylene as its raw fabric,it's far produced via special drawing twisting and floor treatment. as compared with steel fiber, it has benefits of acid, alkali resistant, exceptional tensile, easy dispersing, consolation for creation and no harm to device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000Co

Contact Now