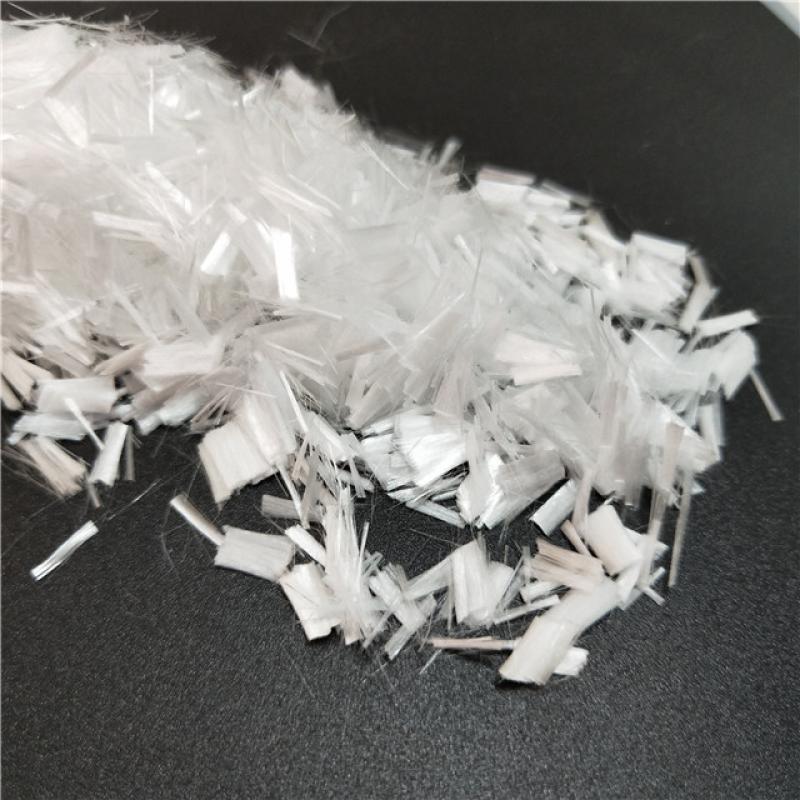

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

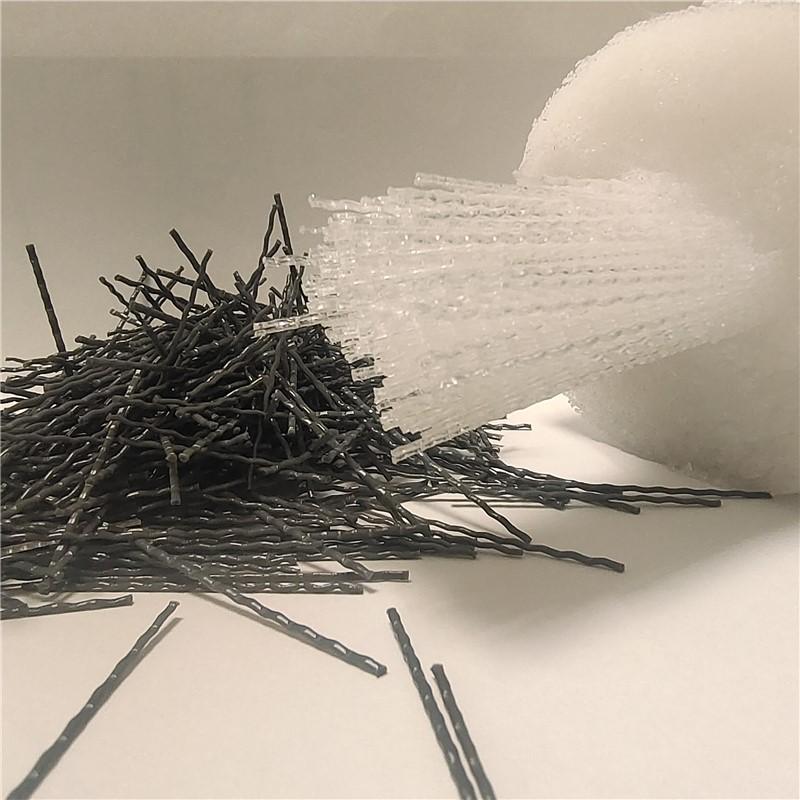

Product DetailsTwist Bundle PP Fiber Bunchy Form Concrete Polypropylene Fibers Twisted package deal pp fiber Bunchy Form Concrete Polypropylene Fibers is superior for replacement of steel fiber. with polypropylene as its raw fabric,it's far produced via special drawing twisting and floor treatment. as compared with steel fiber, it has benefits of acid, alkali resistant, exceptional tensile, easy dispersing, consolation for creation and no harm to device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000Co

Contact Now

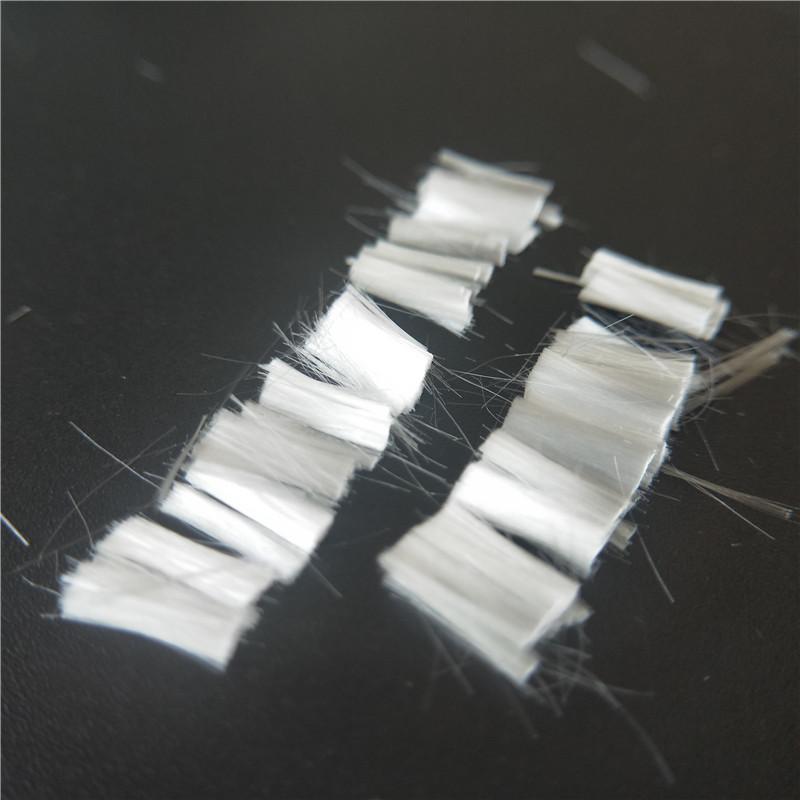

Macro Structural Polypropylene FibersMacro Polypropylene fibers ,also known as plastic steel fiber,is refined from polypropylene as the main raw material through a special production process.The surface of polypropylene crude fiber is rough and uneven.It is a new type of reinforced and toughening material.The product not only has the function of steel fiber,but also has the advantages of synthetic fiber.It can replace steel fiber for the crack resistance enhancement of cement concrete.

Contact Now

20mm~70mm Length Polypropylene Macro Fiber for Concrete Polypropylene fibers are lightweight, have good corrosion resistance, and are widely used in textiles, building materials, insulation materials, and so on.Polypropylene fibers are used as building materials.

Contact Now

Polypropylene Twisted Bundle Fibers 38mm 54mm LengthThe polypropylene twisted bundle fibers are widely used with the continuous development of construction engineering .The polypropylene twisted bundle fiber is made of polypropylene as the main raw material through special parallel drawing and twisted molding process and surface treatment. Alternatives developed for steel fibers.Twisted bundle pp fiber is a material between steel fiber and synthetic fiber.

Contact Now

Polypropylene mono-filament fiber can significantly improve the bond performance between fiber and cement mortar, concrete. This prevents early cracking of cement and concrete, effectively prevent the happening and development of mortar and concrete cracks, so to ensure uniform exudation, prevent segregation and hinder the formation of settlement cracks.

Contact Now

Polyolefin PP Polypropylene Structural PP Synthetic Macro Concrete FibersPolyolefin PP Polypropylene Structural PP Synthetic Macro concrete fibers have market prospects broad.It is made of polypropylene as raw material and processde through special modification and surface molding process.It has both the function of steel fiber and the advantages of synthetic fibers.It has high strength which can effectively strengthen the tensile strength of concrete.Synthetic macro concrete fibers have very good resistance and anti-aging bility,and it can maintain long-term durability in harsh environm

Contact Now

4 MM -19 MM Polypropylene PP Concrete Reinforced Fibers Polypropylene fiber can improve the adhesion of concrete, reduce cracks of concrete in the early stage. As our experiments, only 0.1% fibers by volume can improve the cracking resistance by 70%, and the impermeability increases by 60%-70%. PP fibers are chemically stable, it has excellent corrosive resistance to expand the self-life of your projects. PP fiber increases impermeability, only 0.9Kg/m3 PP fibers can improve it by 70%. The light-weight (0.91 density) of PP fib

Contact Now

50mm-250mm Height HDPE GeocellsA geocell(HDPE Plastic honeycomb Geocell) is a three-dimensional structure made on the basis of a geomaterial, usually made of a plastic material such as high-density polyethylene (HDPE) or polypropylene. Its main function is to form a reinforced structure in the soil, enhance the bearing capacity and stability of the foundation, and thus improve the engineering properties of weak soil.

Contact Now