Product informationComposite geomembrane liner is made with the aid of heat-bonding nonwoven or woven geotextile to hdpe geomembranes with the aid of calendaring processing era.The composite geomembrane liner has the features and blessings of both geotextiles and geomembranes.The geotextile layer will increase critical tensile power and the geomembranes offers super impermeable, leak and moisture proof.They're widely used for landfills, waste water remedy, roads construction, aquaculture, panorama and agriculture, and so on.FeatureHigh tensile strength and tearing strengthExcellent seepage

Contact Now

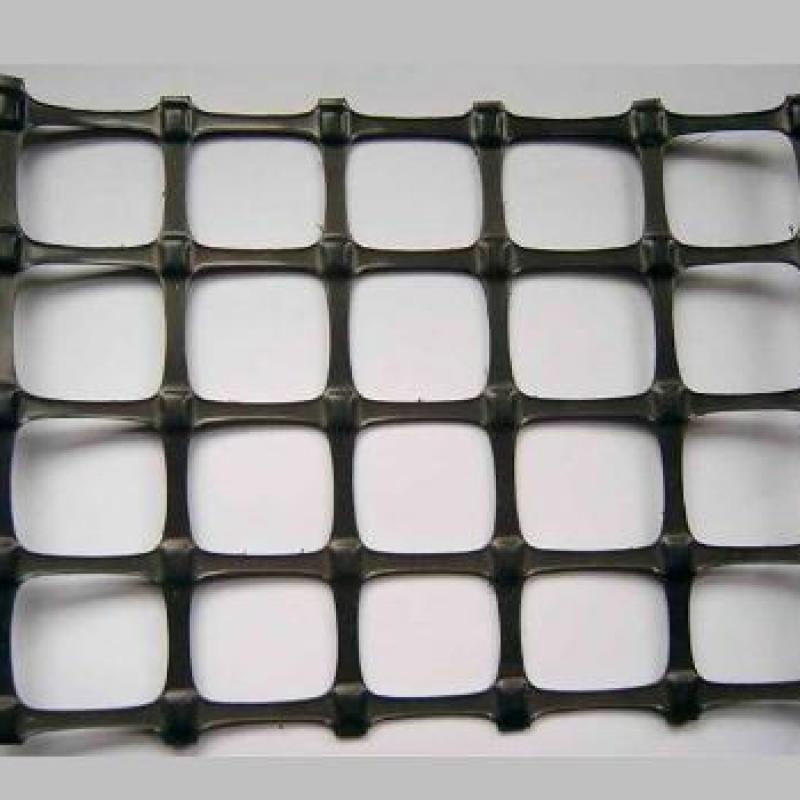

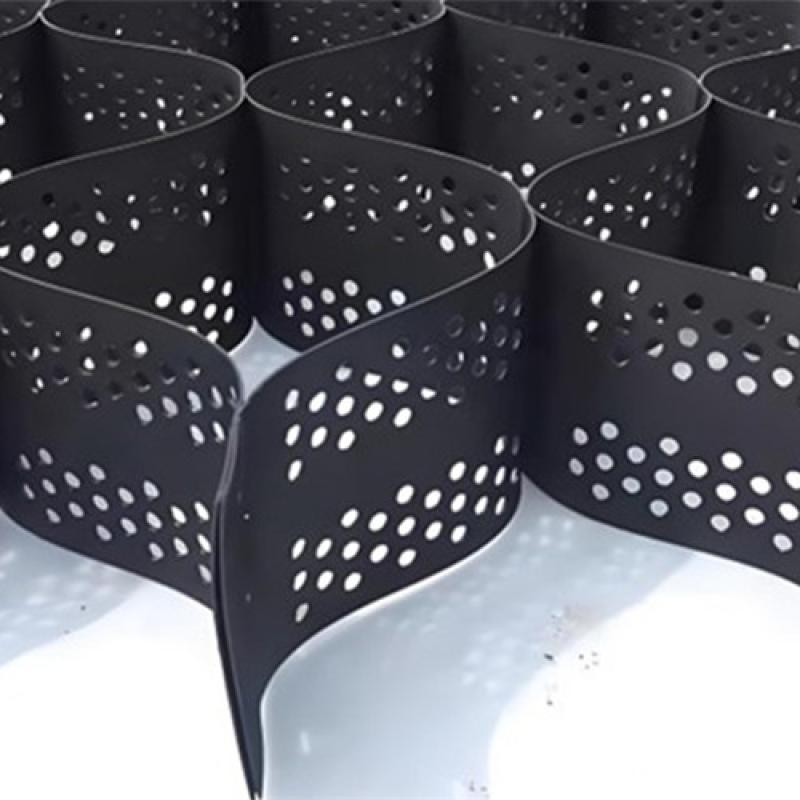

Product DetailsWhen it is be in construction,the hdpe geocell may be pull right into a community and launched into a three-dimensional honeycomb grid.As it crammed in sol,macadam,concrete or other granular materials,constituted to be a production which has robust sidewise restraint and excessive rate of stiffness.ParameterProduct TypeHeight (mm)Welding Distance (mm)Thickness (mm)Tensile Strength of Welding Points (N/cm)Tensile Strength of Commection of Cells (N/cm)Tensile Strength of Yield of Each Sheet (Mpa)Smooth and Not Perforated50MM≤H≤250330MM ≤A≤ 10001.0-1.421002120220Smooth an

Contact Now

Product Details3-d geomat is sort of a gourd network three-dimensional structure for the planting soil, unfastened and bendy, with a ninety% area filling soil, gravel and first-rate stone, plant roots can intrude, at ease, orderly and balanced growth after developing grass mat, turf, soil.The floor tightly collectively, because the plant roots deep under the surface of 30 - 40 cm, forming a protecting layer of inexperienced composite stable.Before the turf grows, it protects the floor of the soil from rain and wind.It can firmly maintain the seeds frivolously distributed at the slope, from the

Contact Now

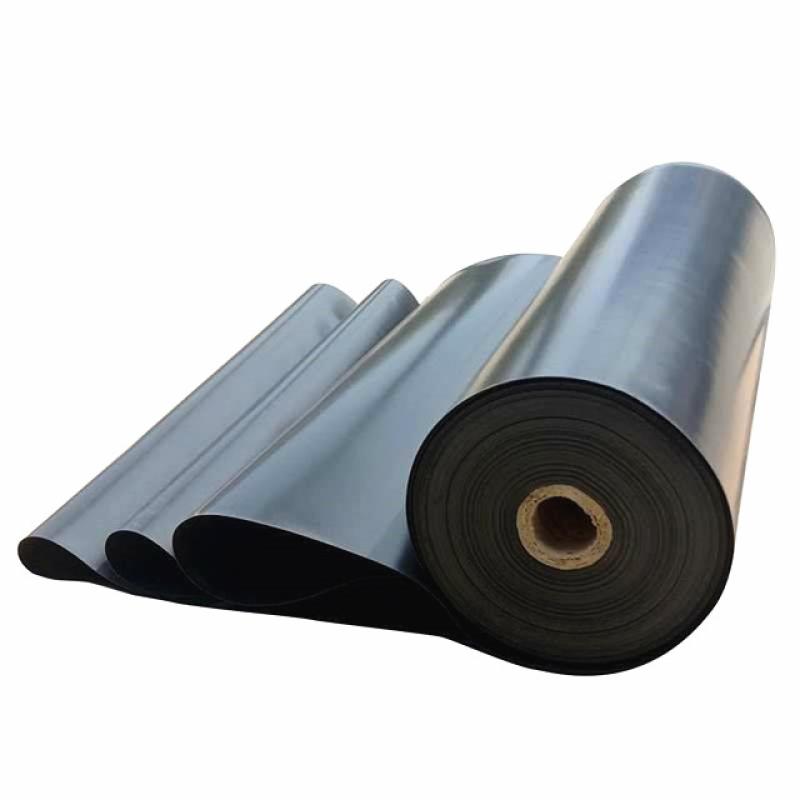

Product IntroductionHDPE Geomembrane Good mechanical properties, high tear strength,Deformation and adaptable, puncture resistance,Anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion,High temperature-resistant, non-toxic,long service life.Water,drainage, seepage, the good effect of moisture, low cost, easy construction.Parameter Test PropertiesunitTest Method Test FrequencyLKMS75LKMS10LKMS15LKMS20LKMS30 Mechanical Properties ThicknessmmD5199Per roll0.751.001.502.003.00 Densityg/ccD1505/D79290,000kg &nbs

Contact Now

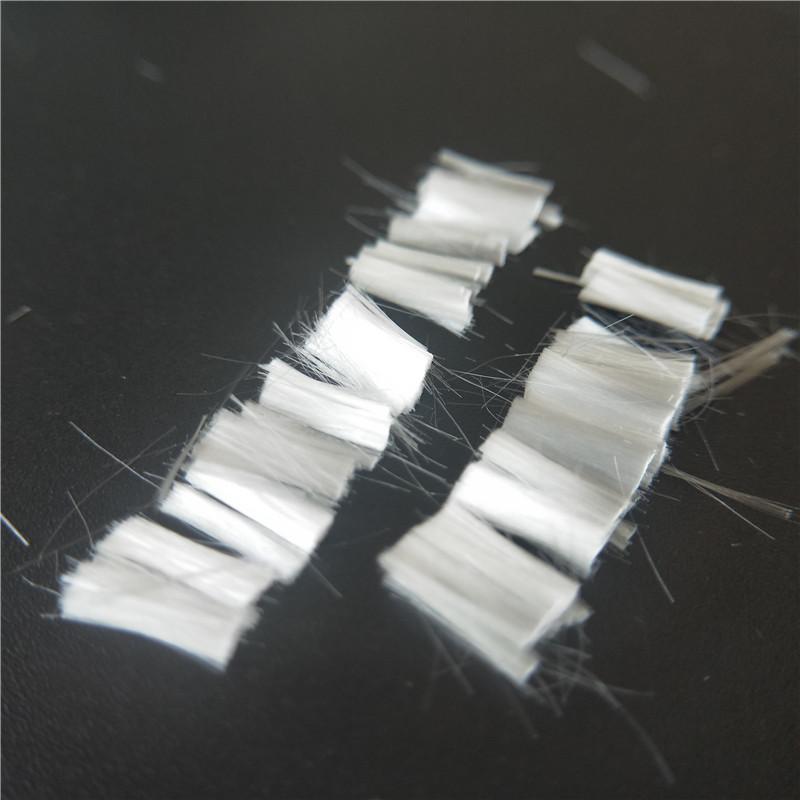

40 MM High Performance Structural Synthetic Macro FibersProduct Details Concrete pp fiber is made by a hundred% virgin polypropylene,adopting unique production system to make high power bundle monofilament fiber. When the fiber is positioned into the concrete,concrete (or mortar) can efficaciously manipulate concrete (or mortar) Micro-cracks which is caused by plas

Contact Now

Product DetailsTextured HDPE Geomembrane is designed and fabricated with either single-sided or double-sided textured surface.Textured geomembrane has a rough surface which can highly improve the friction coefficient which fits more suitable for steep slope and vertical engineering design work which maximize the effective volume of geomembrane, they are also processed with smooth edges to allow for high quality thermal fusion welding between adjacent sheets.All textured geomembranes are made of imported raw material with advanced manufacturing equipment and professional production technology,

Contact Now

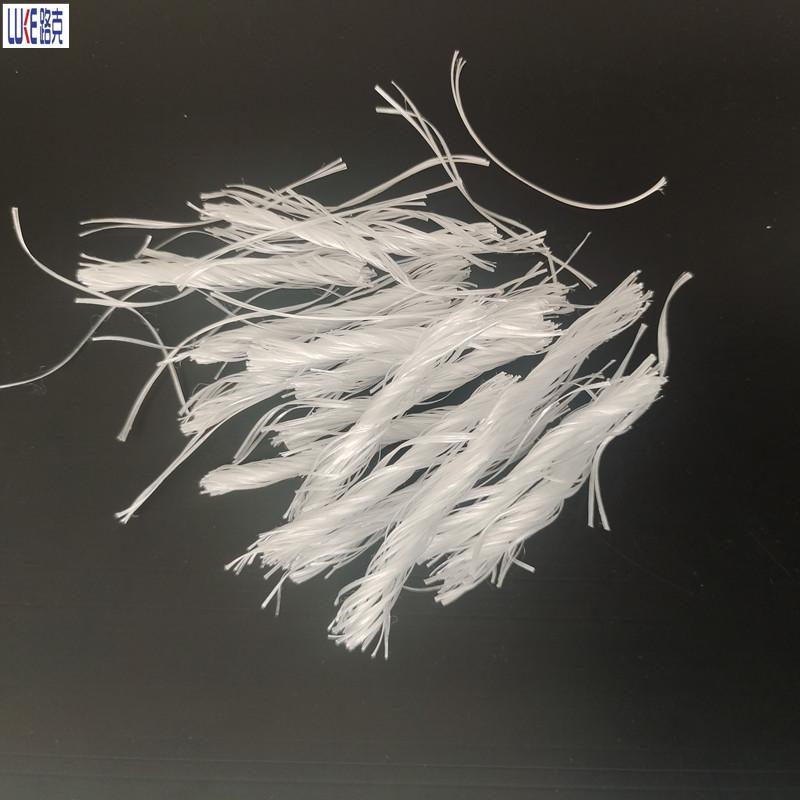

Application Of High Performance Polypropylene Twisted FiberTwisted fiber is a kind of high performance fiber used in construction engineering. When the polypropylene twisted fiber macro pp fiber added to concrete, can significantly improve the crack resistance, permeability resistance, wear resistance, impact resistance, bending resistance and bending resistance of concrete.

Contact Now

100% Polypropylene Macro PP FiberWith the continuous development of the construction industry,100% polypropylene macro pp fiber is used widely in bridge engineering and its large-scale construction projects.Let's first understand what is macro pp fiber,macro pp fiber is made of 100% polypropylene as its raw material,its produced by special molding process and surface modification.It can replace steel fiber with in concrete.so,it is also called imitation steel fiber,which is a new type of concrete additives.As concrete additives pp macro fiber has many advantages in concrete engineering:Add

Contact Now

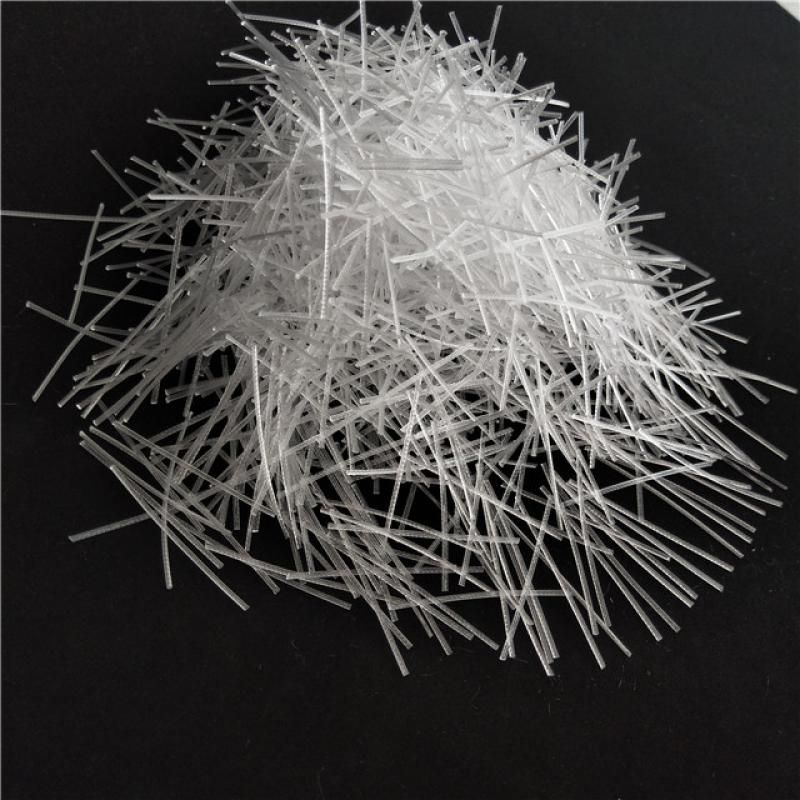

12mm Polypropylene Fiber Mixed in ConcreteQuality Compliance EN-14889-2Polypropylene Micro fiber is one kind of Concrete Fiber and Polypropylene Fiber, it is 100% new polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle monofilament fiber.

Contact Now

19mm Polypropylene Monofilament Fiber Martor FiberFiber mortar is a new material that uses fiber to increase its strength and toughness.It is made of polypropylene fiber as raw material.The length standards of these fibers have an important effect on the properties of mortar.At present, the polypropylene fiber length standard of fiber mortar is generally between 3mm and 25mm.

Contact Now