Product information3D Turf Reinforcement Mats Geomat Price HDPE Plastic Mesh for Slope3D Turf Reinforcement Mats are pp mesh mat composited with twine mesh, that is galvanized in case of erosion manipulate.The structure lets in enough area for maintaining the soil and grass growing.

Contact Now

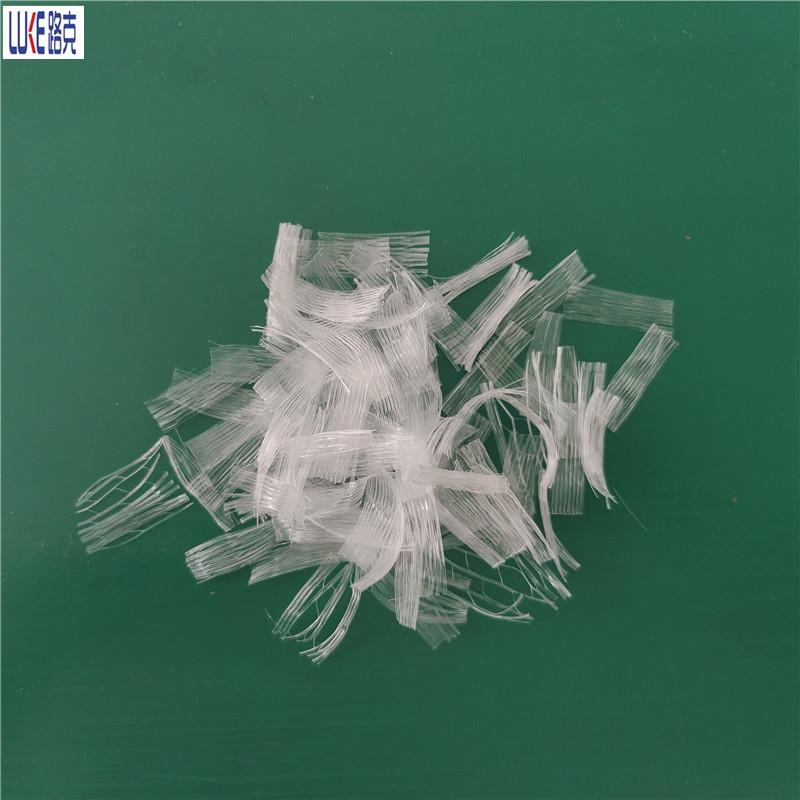

Macro Structural Polypropylene FibersMacro Polypropylene fibers ,also known as plastic steel fiber,is refined from polypropylene as the main raw material through a special production process.The surface of polypropylene crude fiber is rough and uneven.It is a new type of reinforced and toughening material.The product not only has the function of steel fiber,but also has the advantages of synthetic fiber.It can replace steel fiber for the crack resistance enhancement of cement concrete.

Contact Now

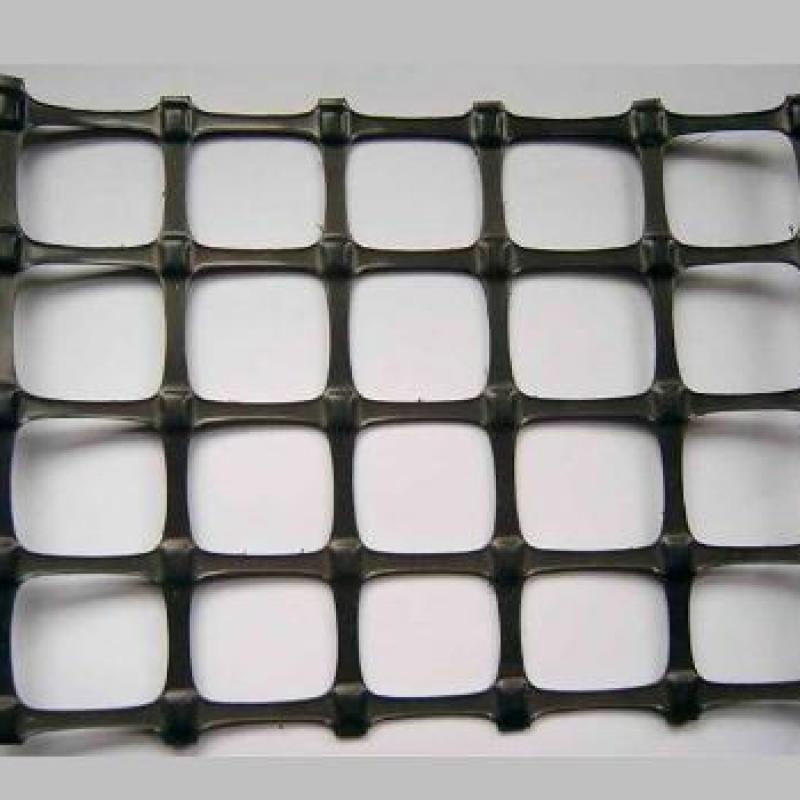

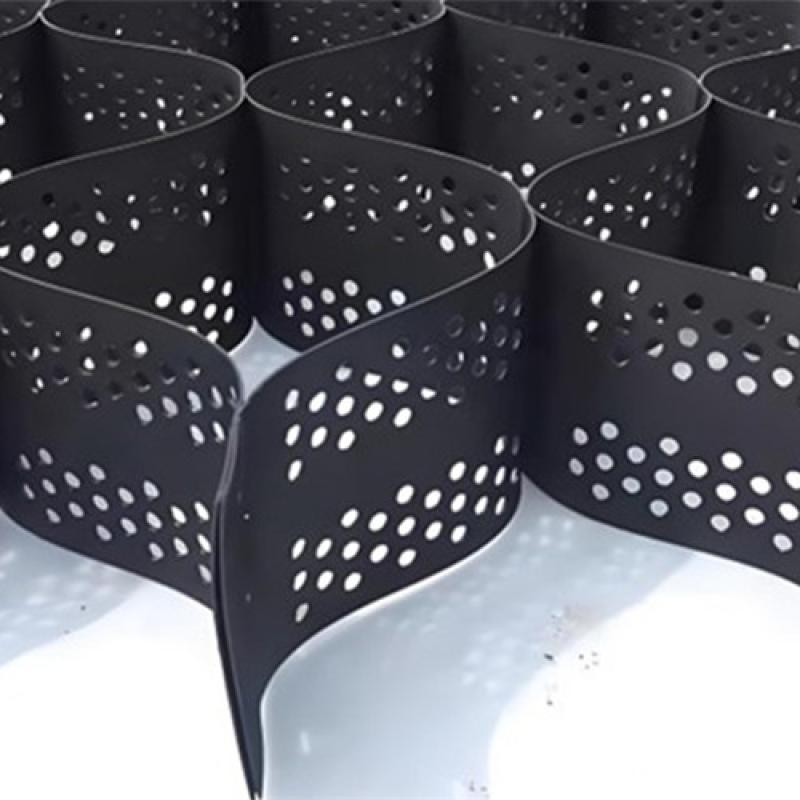

Product DetailsSteel plastic geogrid reinforcement can correctly enhances the bearing capacity of basis and stops the soil from lateral displacement due to its excessive friction coefficient and the bearing capability.

Contact Now

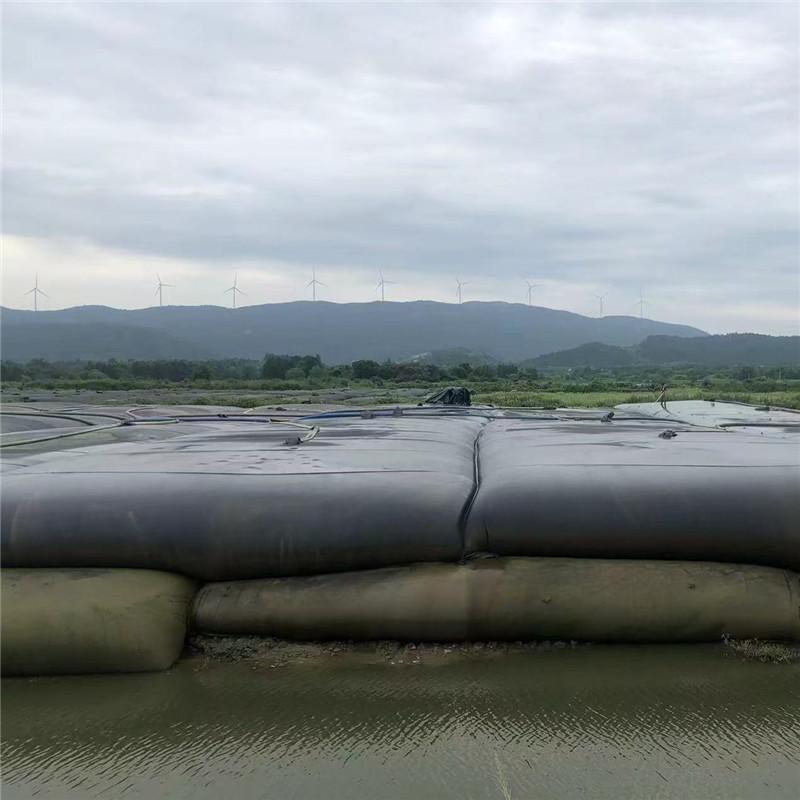

Sludge Dewatering Geo Pipe BagSludge dewatering pipe bag is also geotechnical pipe bag, sludge dewatering bag,which is a large pipe bag and inclusion made of high-performance polypropylene geotextile. Its length and width can be adjusted according to actual needs. This material has high strength and durability and can be used in a variety of harsh environments. Can be used for drainage, filtration,isolation,dehydration.

Contact Now

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contact Now

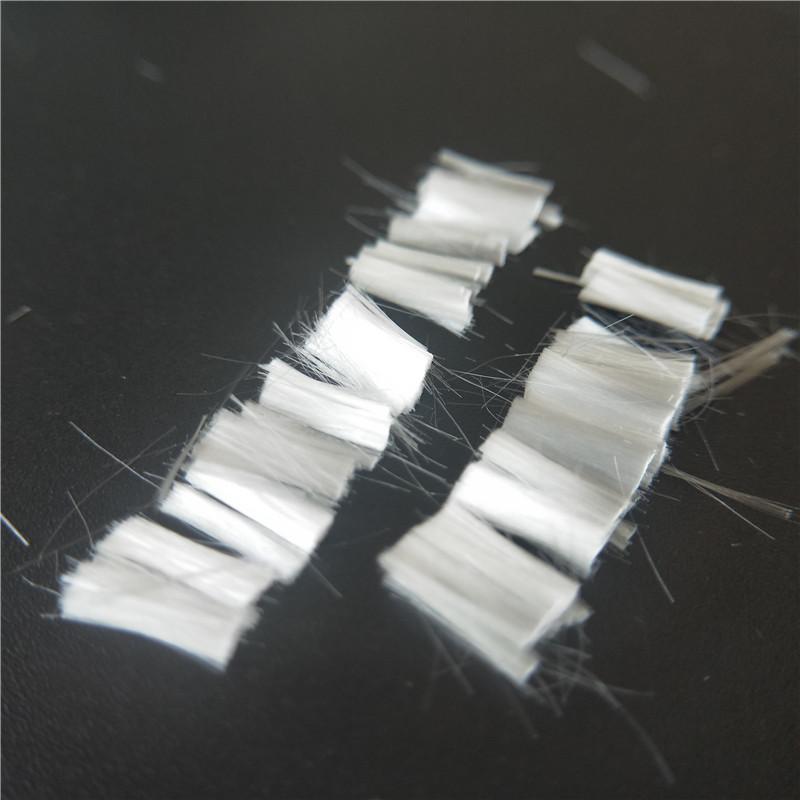

Concrete PP Fiber Twisted BundleTwisted bundles PP fiber is developed for replacement of steel fiber, with polypropylene as its raw material;it is produced by special drawing twisting and surface treatment.

Contact Now

China Manufacturer Concrete Macro FibersWe are concrete macro fibers China manufacturer.we mainly product are PP macro fiber,PP micro fiber,embossed fiber、PP mesh fiber,reinforced fiber.Their advantages are as follows:1、Concrete macro fibers have high strength:the tensile strength of polypropylene imitation steel fiber is higher than that of ordinary steel fiber,which can effectively strengthen the tensile strength of concrete.2、China manufacturer fibers have good durability.It has very good corrosion resistance and anti-aging ability,and can maintain long-term durability in harsh environ

Contact Now

HDPE Waterproof Dimple Drain BoardDimple drain board is the use of foundation or blow molding method to produce high density polyethylene(HDPE) geomembrane,pressed on geomembrane pressure after the special craft the closed swelled the frustum of a cone shape,having a three-dimensional space and some support stiffness,liquid,gas can flow excreted within its plate. Drainage protection board is widely used in the field of civil engineering.The technical parameters of water proof dimple drain board:NoLK-H08LK-H10LK-H12LK-H16LK-H20LK-H25LK-H301MaterialHDPEHDPEHDPEHDPEHDPEHDPEHDPE2Drain height(

Contact Now

China Manufacturer Macro PP Concrete FibersPolypropylene Fiber is a new type of concrete material.Its with polypropylene fiber as its raw material.It is produced by special molding process and surface modification.The surface of polypropylene crude fiber is rough and uneven.It is a new type of reinforced and toughening material.The product not only has the function of steel fiber,but also has the advantages of synthetic fiber.Macro PP Fibers have advantage of acid,alkali,It has high strength corrosion resistance,high temperature resistance, strong gripping force with concrete, and easy constru

Contact Now

Wholesaler Polypropylene Fiber Mesh PP FiberPolypropylene mesh fiber is also known as polypropylene fiber mesh.It is widely popularize around the world because of its unique functions.With polypropylene as its raw material,It is produced by special technology.The most important advantage of reinforcing mesh polypropylene fiber is that it can enhances the performance of concrete, improving the durability and crack resistance of concrete.

Contact Now