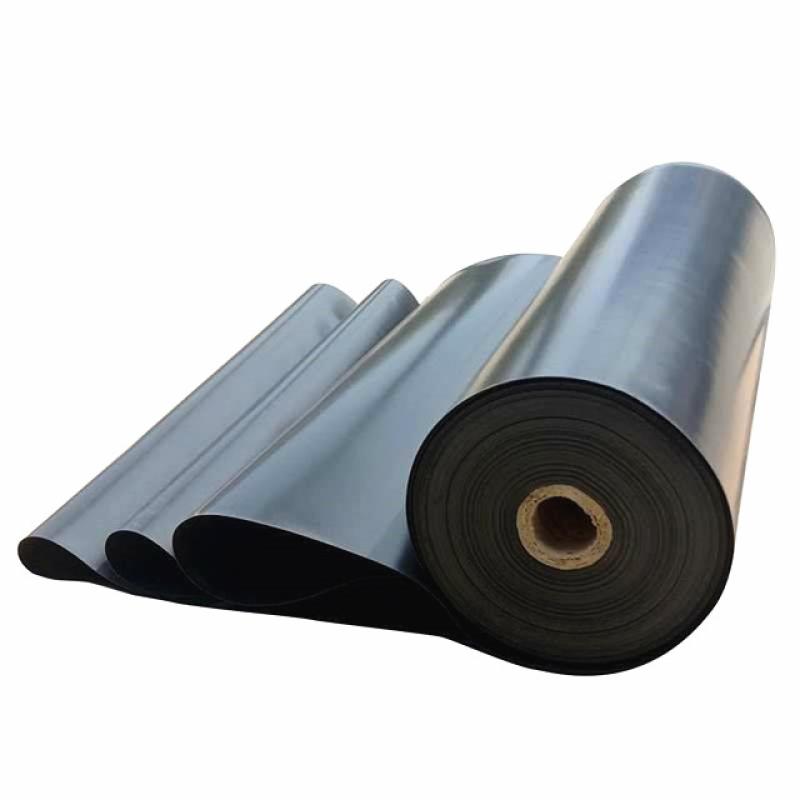

HDPE Geomembrane Fish Farm Pond liner is produced from high density polyethylene resin by film-blowing process, adding carbon black, antioxidant, anti-aging and UV-resistance component. Now it is the most widely used products for swimming pools, artificial lake, artifical river and water containment applications. After testing, the quality meets the ASTM standard GM GRI 13 completely.We confirm : 100% virgin HDPE + 2~3% carbon black + antioxidant, anti-aging and UV resistance component.We supply : Advanced equipment + 24 hours production + test each roll+

Contact Now

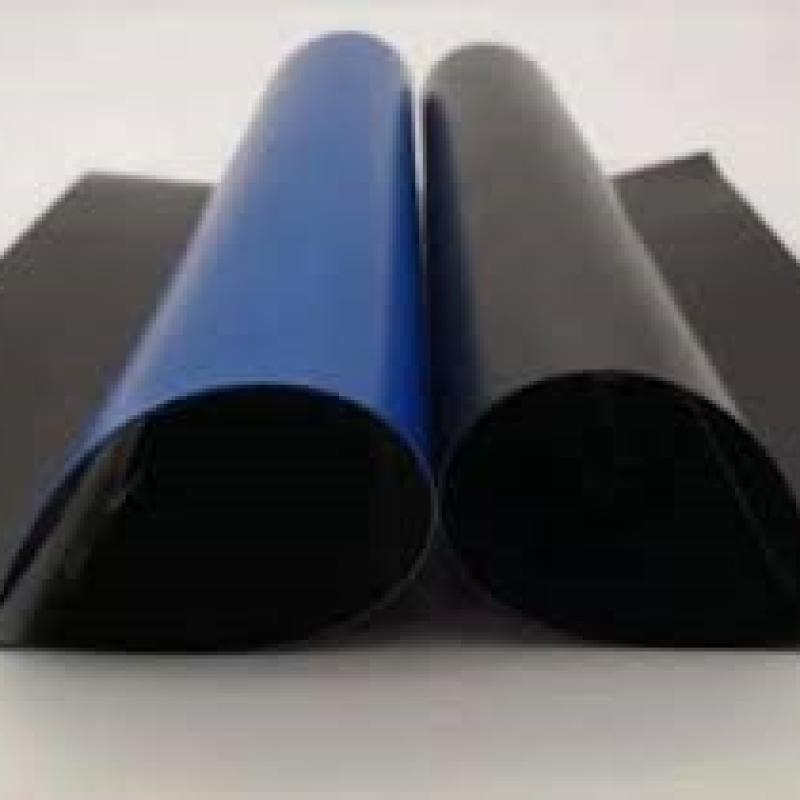

Product informationComposite geomembrane liner is made with the aid of heat-bonding nonwoven or woven geotextile to hdpe geomembranes with the aid of calendaring processing era.The composite geomembrane liner has the features and blessings of both geotextiles and geomembranes.The geotextile layer will increase critical tensile power and the geomembranes offers super impermeable, leak and moisture proof.They're widely used for landfills, waste water remedy, roads construction, aquaculture, panorama and agriculture, and so on.FeatureHigh tensile strength and tearing strengthExcellent seepage

Contact Now

Polypropylene PP Twisted Fiber Macro Fiber For ConcreteWhat is polypropylene PP Twisted Fiber?Polypropylene pp twisted fiber for concrete is a high-performance macro fiber,mainly used in construction engineering.It is developed for replacement of steel fiber,with polypropylene as its raw material.It is produced by special drawing twsiting and surface treatment.Polypropylene PP twisted fiber compared with steel fiber,it can resist acid&alkail corrosion and are suitable for various structural concrete.

Contact Now

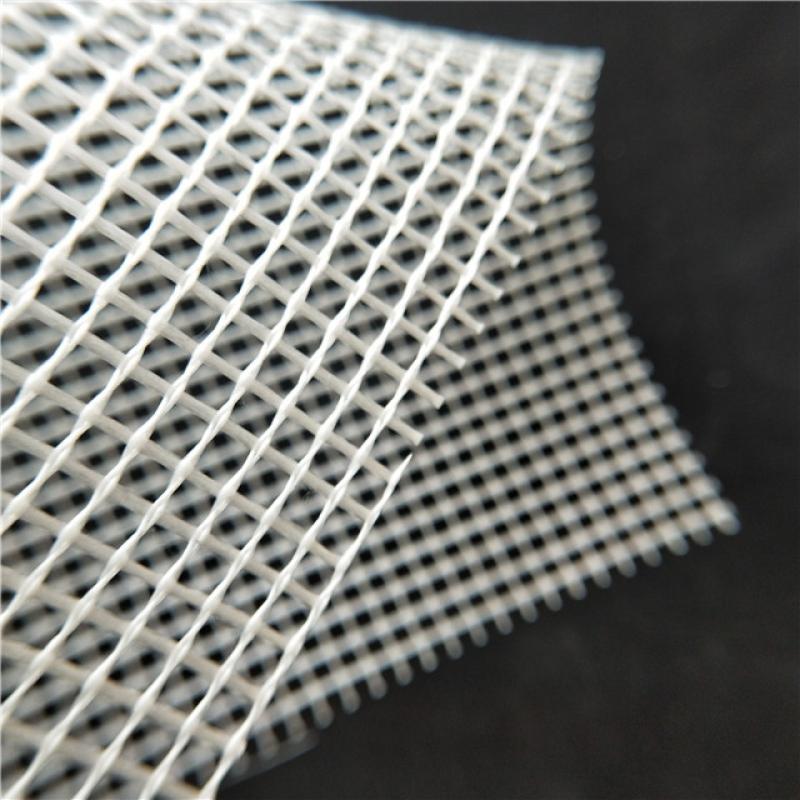

80-160 G Fiberglass Mesh Fabric For Wall Construction Fiberglass mesh is woven by means of c-glass fiberglass yarn, and then coated by way of alkali resistant glue.specifically has excessive property for Acid-resistant and excessive electricity for concrete reinforcement.Fiberglass mesh has been the primary simple materials for structures, and welcomed in europe.1.Factory supply2.Quick deliver

Contact Now

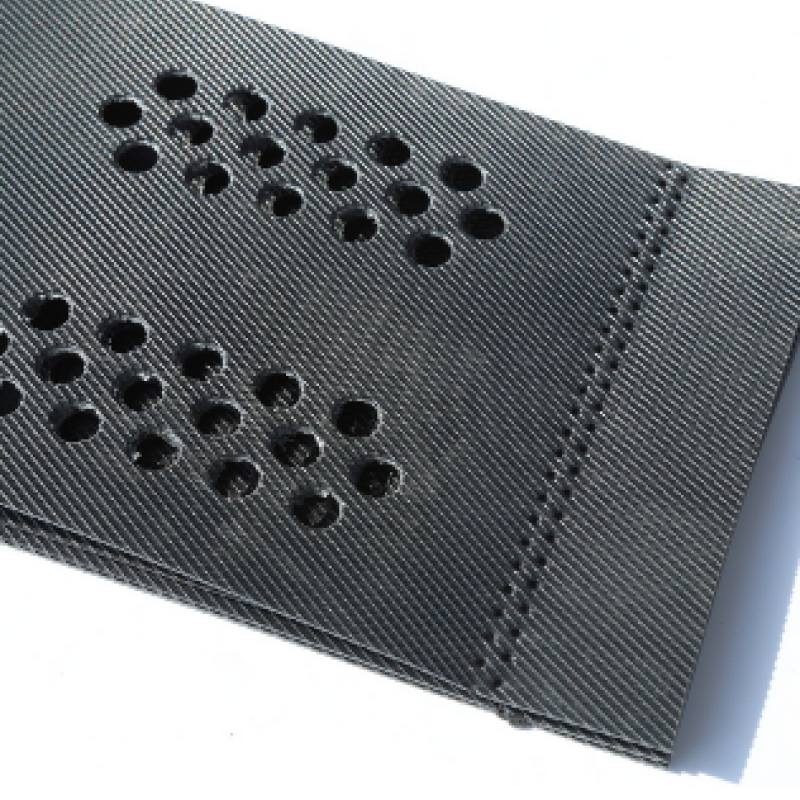

Polypropylene Macro Synthetic Fiber are made from polypropylene resin the steel imitation fiber has the advantages in high breaking strength, good dispersion, and strong grip strength.(g/cm3)Density0.91-0.92(mm)Length20~60ColorBlack or white or Grey Shape waved, embossed(MPa)Tensile Strength≥500Elastic Modulus(MPa)≥4000(mm)Diameter0.8~1.3mm(%)Crack Elongation>15Melting Point160-170℃ Resistance Acid alkalistrongFunctions:1、 Can reduce damage when happened earthquakes and other natural disaster

Contact Now

Product DetailsDimple drain board is the usage of basis or blow molding technique to supply excessive density polyethylene (hdpe) geomembrane, pressed on geomembrane pressure after the particular craft the closed swelled the frustum of a cone shape, having a three-dimensional place and a few guide stiffness, liquid, gasoline can go with the flow excreted within its plate.That is a latent many features substances, using this plate can be without trouble built out of the overhead layer, using overhead layer usual drainage, exhaust passage, at the equal time to apply the overhead layer reaches lo

Contact Now

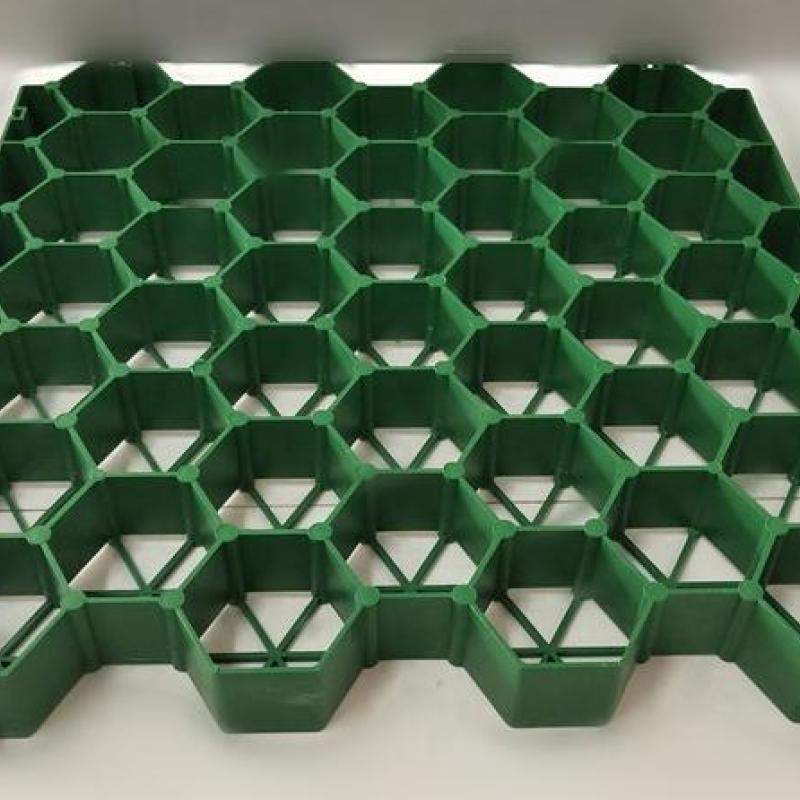

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

Polypropylene Synthetic Fiber for Shotcrete(wave shape Polypropylene Macro Fiber for Concrete)Polypropylene Synthetic Macrofiber for Concrete, like Shotcrete, replace steel fiber.It has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Product DetailsHdpe geocell is manufactured from a new form of high strength geosynthetic, that is famous with each home and abroad, according with gb/t 19274-2003 implementation of the necessities, which welding the reinforced hdpe sheets with the aid of way of the immoderate-energy ultrasonic and forming to be a structure of 3-dimensional reticular formation this is without trouble folding.And reachable for transportation.Whilst it's far be in introduction,the hdpe geocell can be pull right into a network and launched into a 3-dimensional honeycomb grid.As it filled in sol,macadam,concre

Contact Now

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now