Luke PP Dewatering Bags Geotube Bag

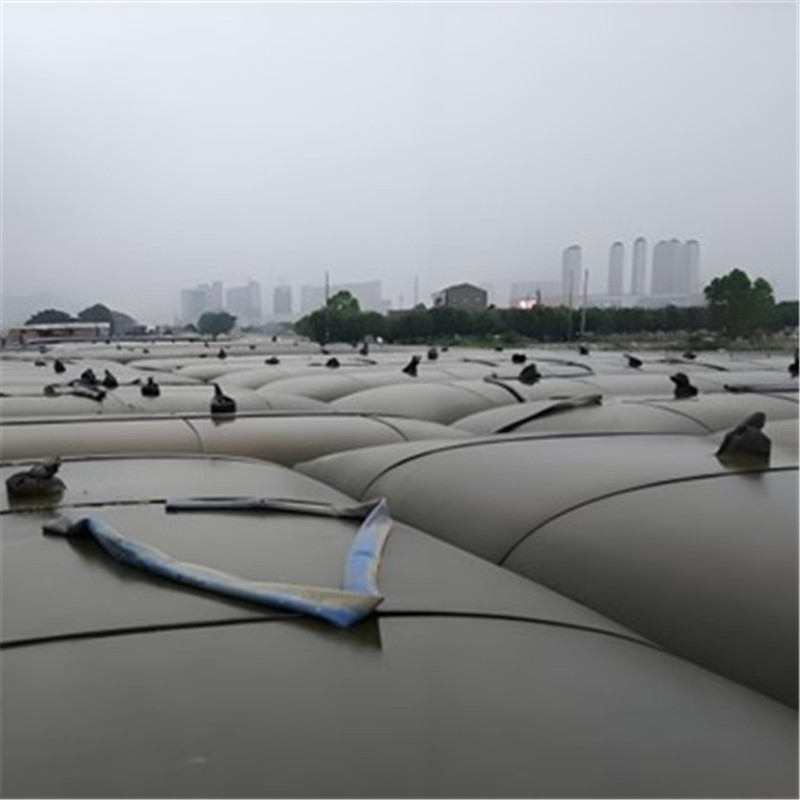

PP dewatering bags geotube bag can rapid dehydration, significantly improve dehydration efficiency.

Environmental protection,energy saving and no pollution.

Good filtration performance.

High strength, corrosion resistance, not easy to aging.

PP sludge dewatering pipe bag can be used in large and small wastewater treatment projects and sludge dewatering projects.

Flexible design and convenient transportation.

Luke PP Dewatering Bags Geotube Bag

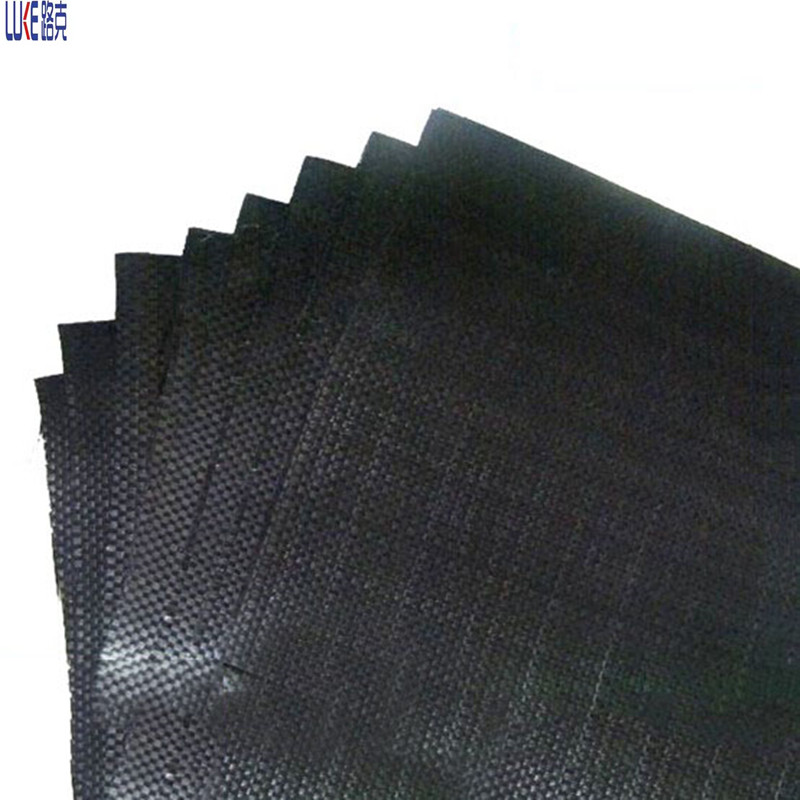

The silt dewatering pipe bag is usually woven from a special polymer material and has a filter structure. The equivalent aperture design of the dewatering geotube bags allows it to effectively filter moisture while resisting the long-term effects of UV rays, guaranteeing its durability . Sludge dewatering agent is added to the inside of the pipe bag to promote the separation of mud and water. The water seepage through the filter structure of the pipe bag, while the sludge remains in the pipe bag . The working principle of the sludge dewatering geotube bag mainly depends on its special structure and material characteristics, and realizes the dehydration and solidification of the silt through physical and chemical action.

Luke PP dewatering bags geotube bag technical parameters:

Product Name | Tensile Strength(T) | >90KN/m | |

Material | PP | Elongation(T) | 10% |

Diameter range | 1-20m | Tensile Strength(L) | >70KN/m |

Length | ≤200m | Elongation(L) | 15% |

Equivalent Aperture | 0.3-1.0m | UV Resistance | Strong |

Bursting Strength | >7kN/m | Permeability | >12L(m2·s) |

The feature of geotube Sludge Dewatering Bag:

◆High acid and alkali corrosion resistance.

◆High strength,low deformation

◆High flexibility: the geotechnical pipe bag can be customized according to engineering needs to adapt to different terrain and soil conditions.

◆Good reinforcement effect: Through filling materials, the geotechnical pipe bag can effectively improve the bearing capacity and stability of the foundation.

◆Environmentally friendly

◆Geotube Sludge Dewatering Bag dehydration effect is good and volume reduction.

Packaging and delivery:

Packaging:standard packaging or customer’s requirements

Leadtime:within 7-10 days after receiving the deposit payment.

Dewatering Process:

A typical sludge treatment process consists of four treatment stages. The first stage is sludge thickening, the main purpose is to reduce the initial volume of sludge; The second stage is sludge digestion, so that the organic matter in the sludge decomposition; The third stage is sludge dewatering to further reduce sludge capacity. The fourth stage is sludge disposal, which uses some way to consume the final sludge.

After-sales service:

Our company provides a one-stop service, technical staff to provide all-day online support to solve the related technical problems of Luke PP dewatering bags geo tube bag in time. Thank you for your love of our products.

Flood control woven geotechnical tube bag application:

◆Used for flood control,emergency, increase temporary height,prevent landslide erosion,etc.

◆Used to drain water from flooded fields or yards.

◆Flood control woven geotechnical tube bag is used in tunnels,underground parking lots,subways and other low-lying places to increase the height of flood prevention.

◆In road construction, bridge construction and other sites, used for water absorption.

◆Suitable for industrial and mining enterprises that need rapid water removal.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible