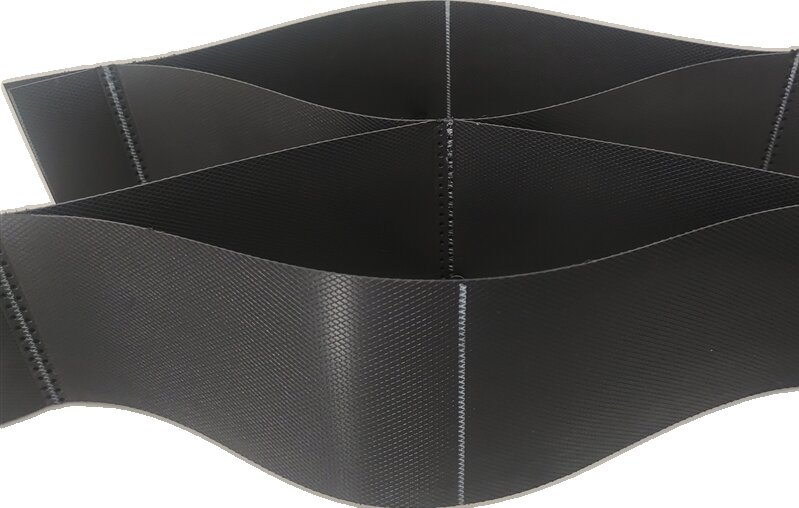

50mm-250mm Height HDPE Geocells

The HDPE geocells are available in a variety of heights and thicknesses to meet different engineering needs.

Flexible, transport can be folded, easy to transport.

Light material, wear resistance, stable chemical function, light oxygen aging resistance, acid and alkali resistance

The geocell can prevent slip, prevent deformation, enhance the bearing capacity of the roadbed and the effect of loose load.

50mm-250mm Height HDPE Geocells

A geocell(HDPE Plastic honeycomb Geocell) is a three-dimensional structure made on the basis of a geomaterial, usually made of a plastic material such as high-density polyethylene (HDPE) or polypropylene. Its main function is to form a reinforced structure in the soil, enhance the bearing capacity and stability of the foundation, and thus improve the engineering properties of weak soil. The geocell with different height and thickness has different bearing capacity, construction influence and application field.A geocell is a structural geomaterial made of high-density polyethylene or polyallene. They are usually square or hexagonal in shape, with a grid inside. Geocell is often used in land management and structural strengthening projects.

Technical parameter of 50mm-250mm Height HDPE Geocells:

Product type | Height(mm) | Welding Distance(mm) | Thickness(mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Commenction of Cells(N/cm) | Tensile Strength of Yield of Each Sheet(Mpa) |

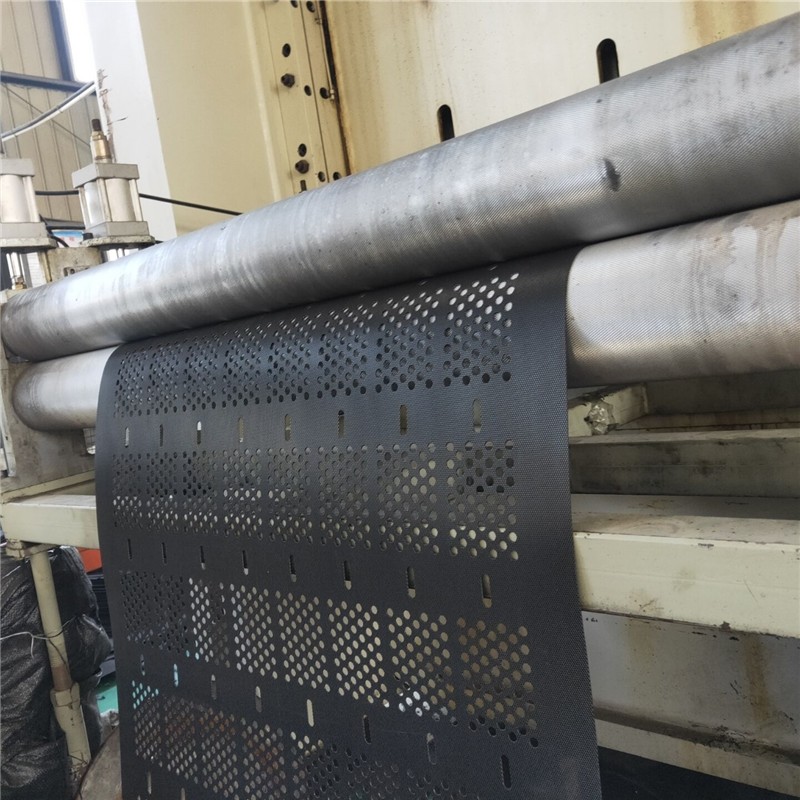

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Remaiks: This is a basic technical specification. All the above technical parameters can be reached according to customer's requirement and other special standard can be carried out by agreement or contract. | ||||||

The feature of geocells HDPE:

1. High strength: The structure of the geocell is very strong and can withstand the challenges of high loads and long-term use.

2. Water permeability: The holes on the surface of the geogrid can allow water to pass through, and the drainage channel is formed inside it to ensure the normal discharge of groundwater and avoid water accumulation.

3. Corrosion resistance: The high-density polyethylene, polypropylene and other materials used in the geocell are not easy to be eroded by chemicals, so they are very durable.

4. Easy to install: the geocell is light in weight, easy to lay and splice, and can be adjusted according to the site situation, convenient and fast.

5. Economic and practical: compared with the traditional reinforcement method, the cost of the geocell is lower and the construction period is shorter, which has a significant role in reducing the investment cost of the entire project and shortening the construction period.

The HDPE lead time and supply ability:

Quantity(square meters) | 1-10000 | 10000 |

Lead time(days) | 3 | To be negotiated |

Geocell for road construction and highway construction,by laying geocell and filling soil particles, the bearing capacity of foundation is significantly improved, and the safe operation of expressway is ensured. In addition, geocels can enhance the carrying capacity and stability of roads, DAMS and other soil structures, reduce soil profile and subsidence risks, and protect land and water resources. Its three-dimensional grid design can effectively distribute the load, reduce the pressure of the soil, and prevent the soil from moving and sinking.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible