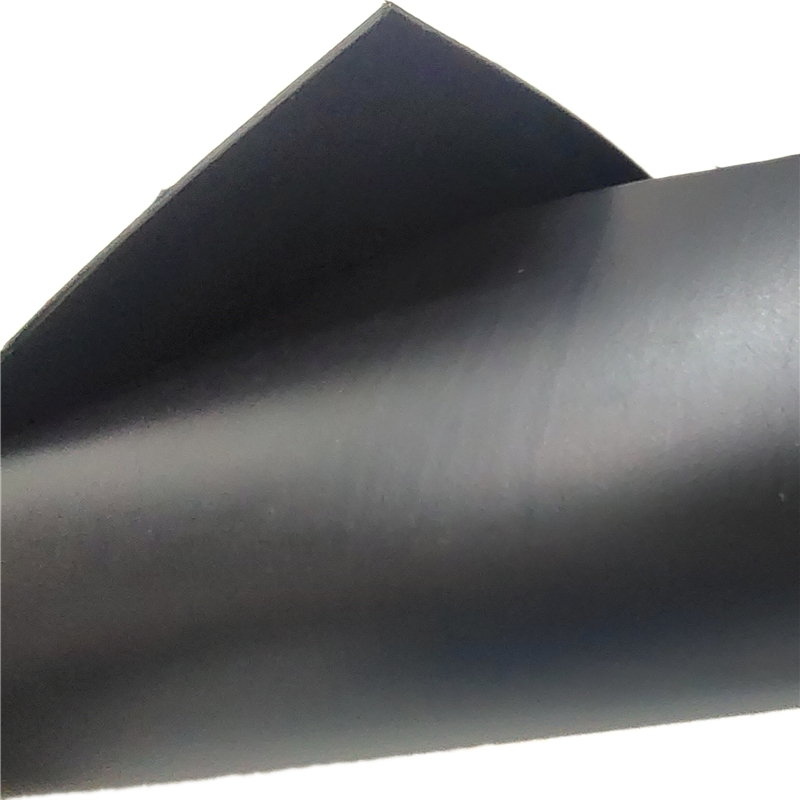

High Quality Waterproof HDPE Geomembranes

High quality waterproof HDPE geomembrane integrates anti-seepage and drainage, and has the functions of isolation and reinforcement.

LuKe HDPE geomembranes have high composite strength, high peel strength, high puncture resistance.

The geomembrane has strong drainage capacity, large friction coefficient and small linear expansion coefficient.

High quality HDPE geomembrane has good aging resistance, adapt to the environmental temperature range, stable quality.

High Quality Waterproof HDPE Geomembranes

Shandong Luke Composite Materials Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces and operates geotextile, geomembrane, drainage plate, geoglage, grid room, three-dimensional geoglage mat, geoglage mat, composite drainage net, grass grid, etc.

Shandnong Luke Composite Co;LTd. Is professional company on production and sales geosynthetics for years.As HDPE geomembrane manufacturer,our aim is quality first,reputation first!HDPE geomembrane is made of high quality polyetylene raw material.HDPE is the abbreviation of high density polyethylene,so it is also called high density polyethlene geomembrane.

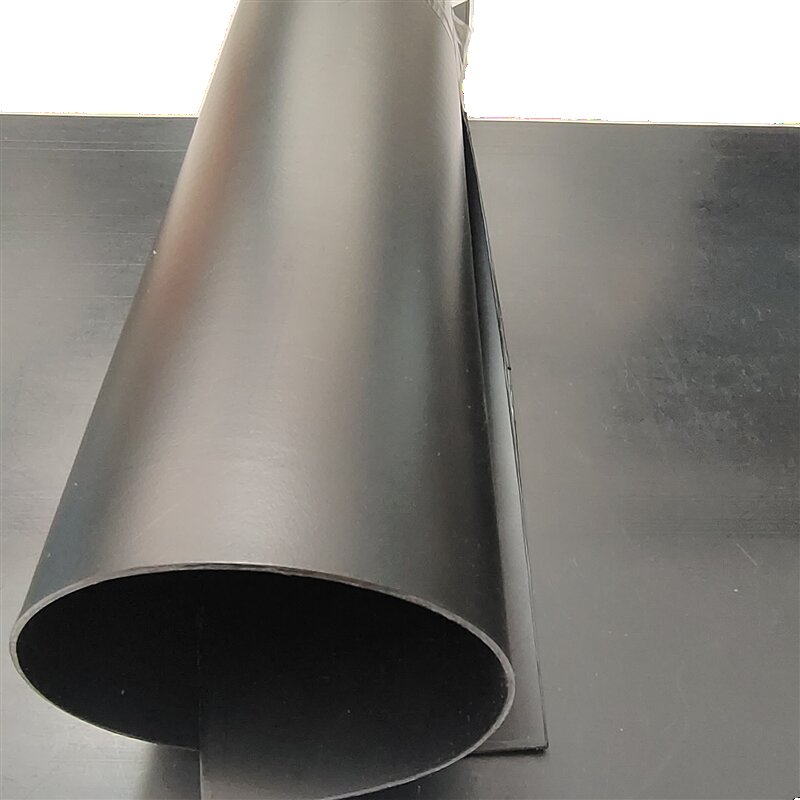

The feature of HDPE geomembranes:

★ High quality waterproof hdpe geomembranes have good physical and mechanic performance.

★ Geomembrane has high tearing resistance, strong deformation adaptability.

★ Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance.

★ Good adaptability to high and low temperature, non-toxicity, long service life.

Technical parameters of HDPE geomembranes:

Test Properties | unit | Test Method | Test Frequency | LK MS75 | LK MS10 | LK MS10 | LK MS10 | LK MS10 | |

Mechanical Propertiers | Thickness | mm | D5199 | Per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90,000kg | 0.94 | |||||

Tensile properties |

D6693 Type IV |

9,000kg | |||||||

Yield strength | KN/m | 11 | 15 | 22 | 29 | 44 | |||

Break strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20,000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture resistance | N | D4883 | 20,000kg | 240 | 320 | 480 | 640 | 960 | |

Stress crack Resistance | Hr. | D5397 | Per GRI GM-10 | 300hr | |||||

Carbon Black Content | % | D4218 | 9,000kg | 2.0-3.0% | |||||

Reference Properties | Oxidative Induction Time | Min | |||||||

Standard OIT | D3895 | 90,000kg | 100min | ||||||

High Pressure OIT | D5885 | 400min | |||||||

Oven Aging at 85℃(retained after 90 days) | % | D5712 | Per each formulation | 55% | |||||

(a)standard OIT | D3895 | ||||||||

(b)High Pressure OIT | D5885 | ||||||||

UV Resistance High Pressure OIT Rerained after1600h | % | D5885 | Per each formulation | 50% | |||||

Roll Size | Roll width | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size Stability | % | 2% | |||||||

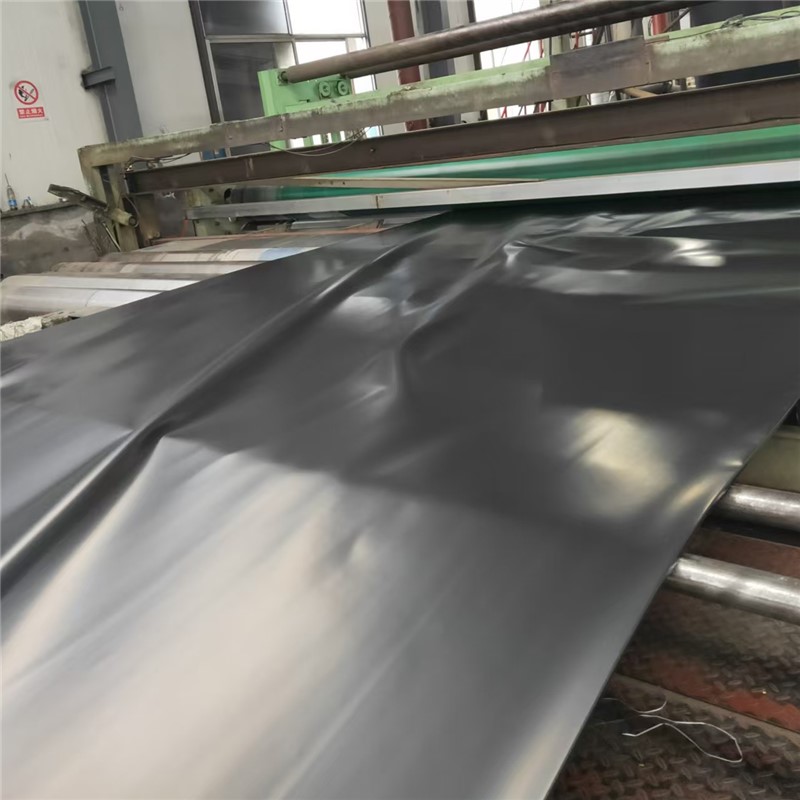

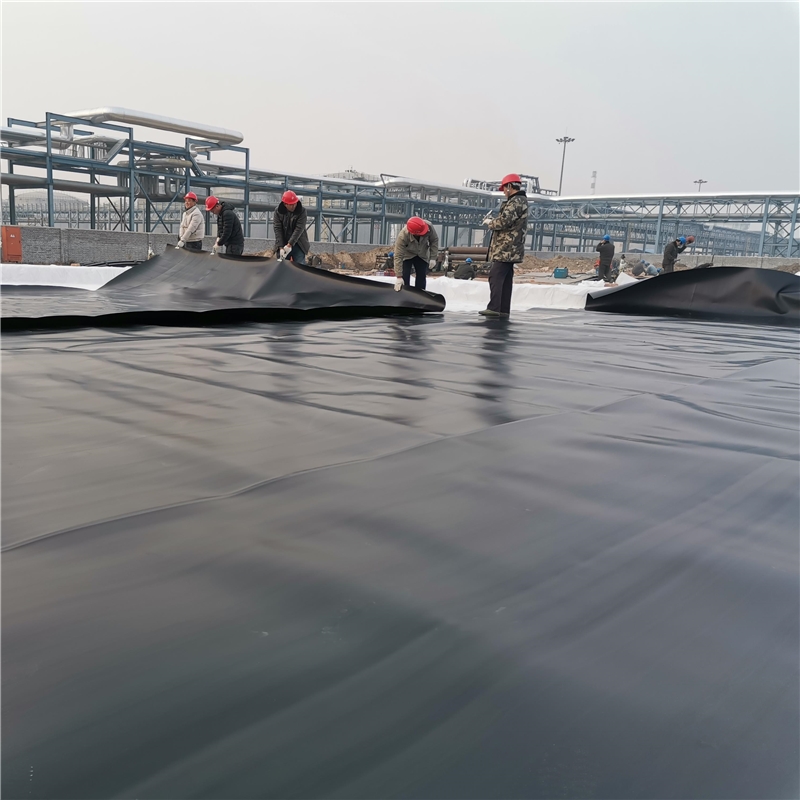

Packaging and samples of geomembrane:

PP woven geotextile bags or PE film. Or according to customers requirements.

We can provid the samples maximum order quantity:1square meter.

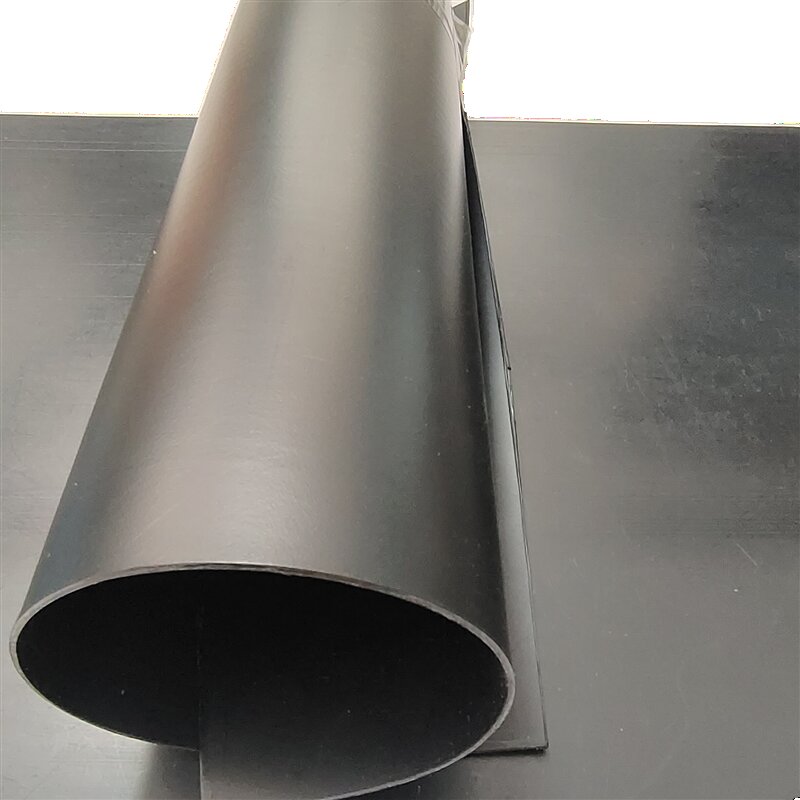

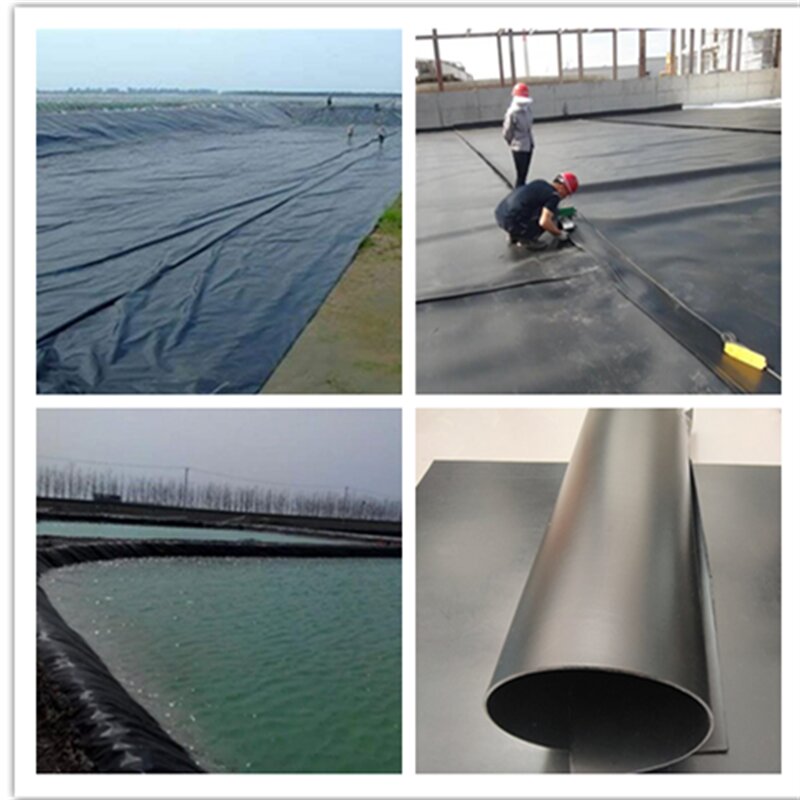

HDPE geomembranes application:

It can be used for Environmental protection and sanitation, water conservancy engineering, garden, petrochemical, mining, aquaculture and other fields.The most commonly used projects are: landfill, sewage treatment plant, artificial lake, reservoir, slope protection, greening, sedimentation tank, HDPE geomembrane for biogas digester, sewage tank, tunnel waterproofing and other projects.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible