Reinforcement Fiber Polypropylene Macro Fiber

Provides good impact resistance, fatigue resistance, shrinkage control and ductility in all grades of concrete.

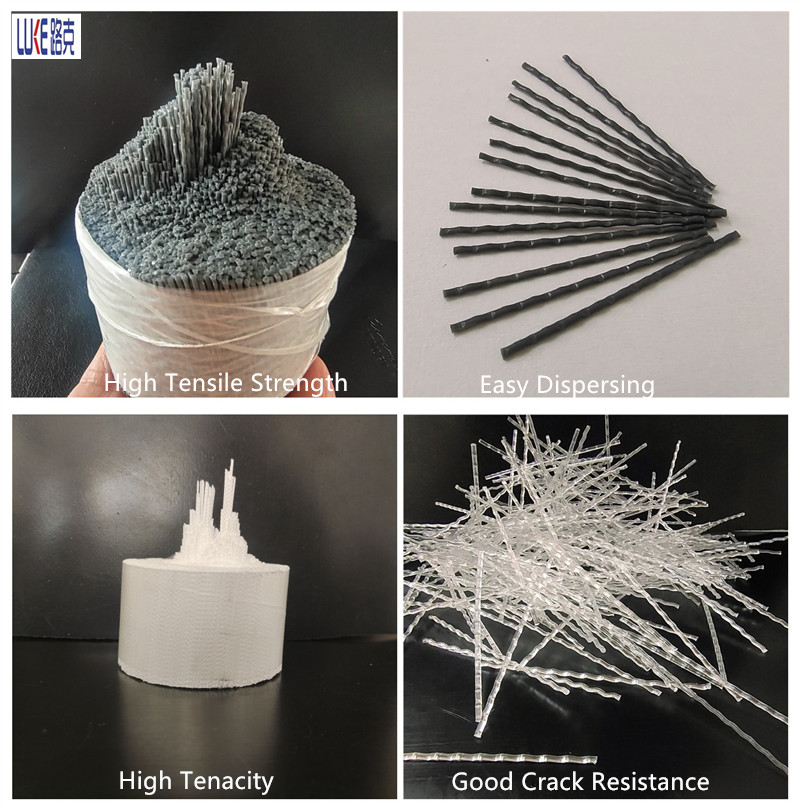

Polypropylene(PP) macro fiber has good tensile strength.

PP macro fiber with in concrete can increase the wear resistance of concrete.

It has can improve the durability of cocnrete structures.

Reinforcement polypropylene fiber can improve the strength and toughness of concrete.

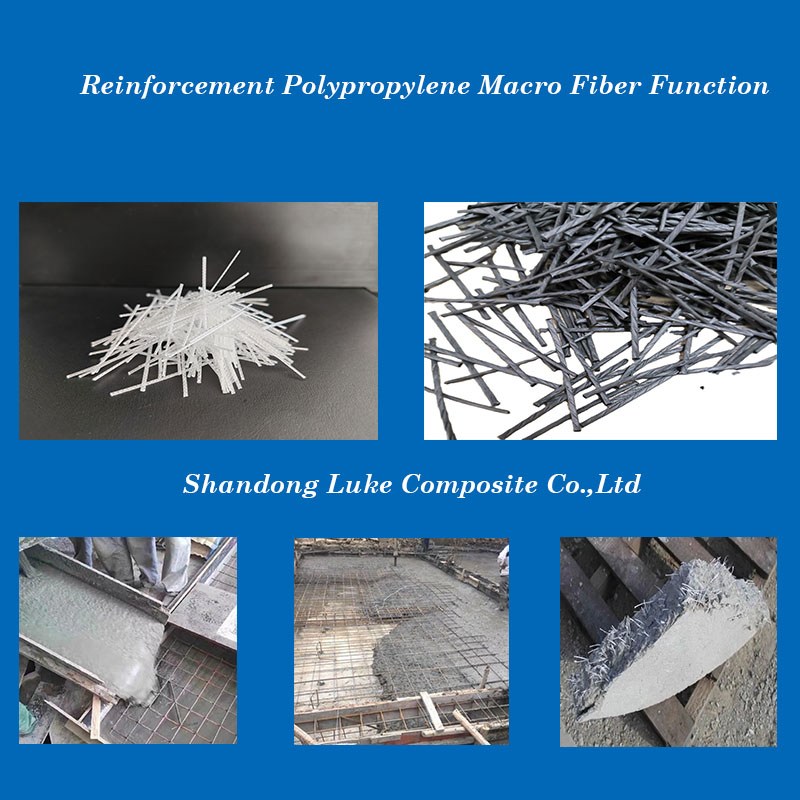

It is usually used instead of steel fiber in concrete engineering.

Reinforcement fiber polypropylene macro fiber

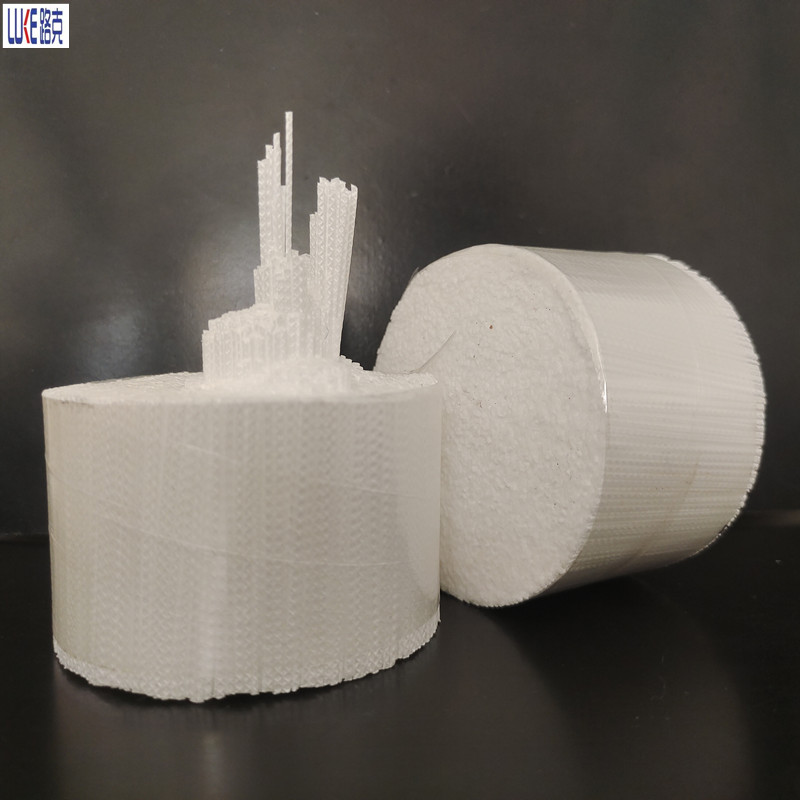

Reinforcement fiber Polypropylene Macro Fiber is a new type of reinforcement material, made of 100% polypropylene as raw material through a special process. It is mainly used for concrete reinforcement, especially in environments requiring high strength and chemical resistance. The pp macro fiber can significantly improve the crack resistance of concrete, and is suitable for various concrete structures, such as prestressed concrete, shotcrete, etc.

The functions of reinforcement fiber polypropylene macro fiber concrete fibers:

◆Can reduce damage when happened earthquakes and other natural disasters.When incorporated into concrete structures, these fibers act as a reinforcement, helping to absorb and dissipate seismic energy, thereby enhancing the overall resilience of the structure

◆Polypropylene macro fiber to reduce the fatal flaws in concrete.

◆It can reduce the leakage of concrete.

◆polypropylene macro fiber concrete fiber protect steel from corrosion.

◆It can improve the durability of concrete structures

◆Increase the wear resistance of concrete

◆Increase the concrete crack resistance,flexural strength,increase toughness of concrete,to extend to the life of concrete binder.

Technical parameters of synthetic polypropylene macro fiber concrete fiber:

Raw Materia | 100%Polypropylene | Length(mm) | 20~70 |

Trademark | LUKE | Tensile Strength | >450(MPa) |

Origin | China | ElasticModulus | ≥4000(MPa) |

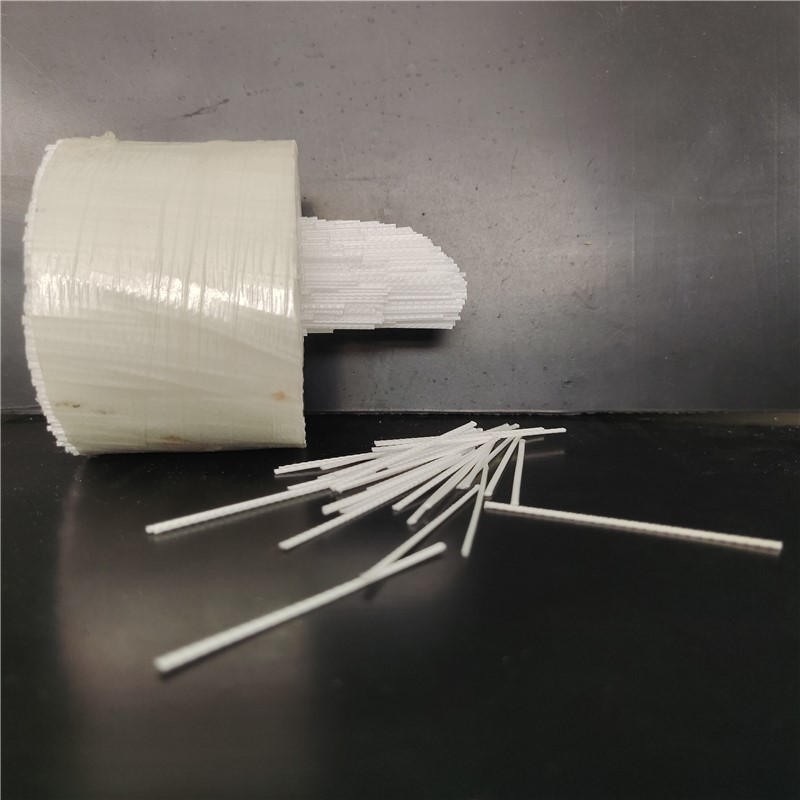

Shape | Curved,Embossed,Waved | Equivalent Dia | 0.9±0.2 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥15% |

Color | White or Black | Melting Piont | 160-170℃ |

Resistance Acid alkali | Strong | ||

packaging of reinforcement fiber polypropylene macro fiber concrete fiber:

Applying instruction of polypropylene fiber pp macro fiber:

1、Dosage:more than 2Kg/cubic meter of concrete.50mm for general crack level,40mm for shotcrete.

2、Choice of polypropylene macro fiber length:50mm for general crack level,40mm for shotcrete.

3、Mixer:Horizontal two-shaft Forced Mixer.

Lead time of synthetic pp macro fiber:

Quantity(tons) | 1-10 | >10 |

Lead time(days) | 3 | To be negotiated |

Our commitment:

Professional equipment, high quality polypropylene concrete fibers, first-class service is your best choice,welcome to our company!

If you want to know more about the crack-resistant polypropylene fiber concrete fiber ,you can continue to ask me questions.

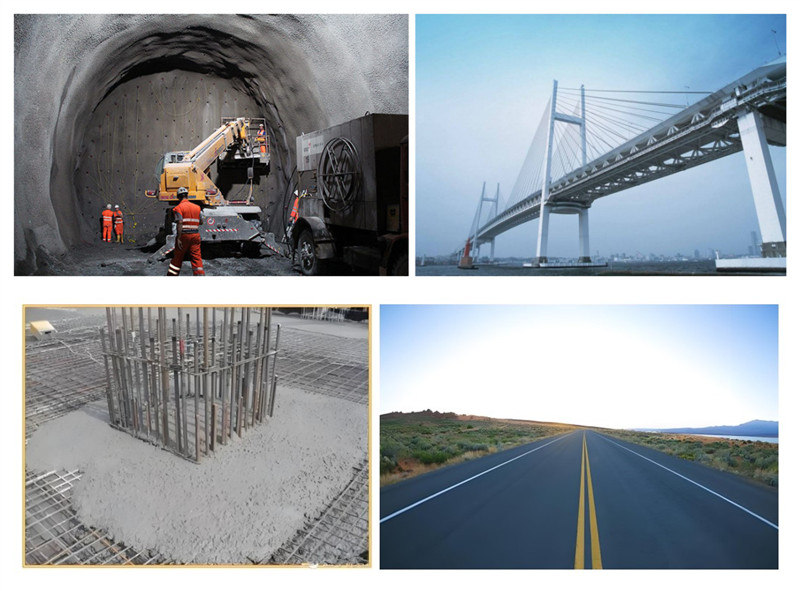

Application of polyproylene fiber concrete fiber:

1、The use of polypropylene fiber concrete fiber in road and highway surfaces significantly improves their durability, and fatigue resistance.

2、It be suit for Toll station,concrete panel、factory floor tunnel,roof,parking lot: Polypropylene fiber concrete fiber is an ideal material for manufacturing precast concrete panels used in the construction of buildings, bridges, and other structures.

3、It be suit for Bridge project,Wharf of the port,water conservancy project.The use of polypropylene fiber concrete fiber in these field provides exceptional durability and resistance to the corrosive effects of sea water and industrial chemicals.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible