Plastic Fiber For Cement Curved Macro PP Fiber

100 % Pure Polypropylene

Good Dispersion

High Tensile Strength

Best for Concrete Reinforcement

One-stop Service,Strict Quality Control

Plastic Fiber For Cement Curved Macro PP Fiber

Product Details

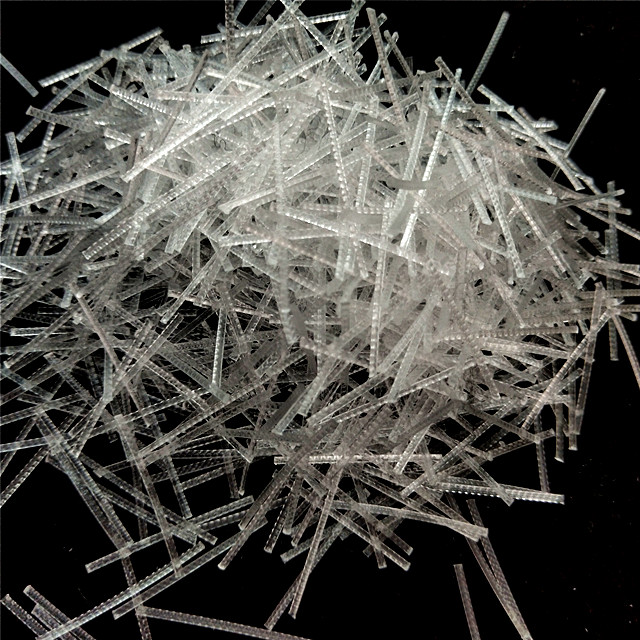

With polypropylene fiber as its uncooked material, curved pp macro fiber is produced with the aid of special molding manner and surface modification.

It has advantage of acid, alkali resistant, amazing tensile, smooth dispersing, comfort for construction and no harm to vehicles and pavement and no

want for unique conservation.

Curved pp macro fiber may be used in place of metallic fiber to beautify the crack resistance of cement concrete and significantly enhance the durability

and flexural of concrete.

Due to special shape, curved pp macro fiber has proper aggregate with concrete and strong bond.

Applying Instruction

1) Dosage: more than 3kg/cubic meter of concrete.

2) Length: 36mm for general crack level, no more than 25mm for shotcrete, best use no more than 35mm.

3) Mix design: In general, no need change the ratio parameters of concrete.

4) Mixer : Horizontal Two-shaft forced Mixer.

5) Stirring requirement: crushed stones, fibers and sands are put into the mixer in succession.

6) Forming conservation: Conservation can be based upon the requirement of ordinary concrete.

Parameter

Density(g/cm³) | 0.91 | Tensile Strength(Mpa) | ≥ 450Mpa |

Length(mm) | 6,12,18,24,36mm...... | Elastic Modulus(Mpa) | >3500 |

Shape | Beam-like Net | Equivalent Dia(μm) | 100±50 |

Material | 100% polypropylene | Crack Elongation(%) | ≥16 |

Water-Absorbency | No | Melting Point | 160-170 ℃ |

Feature

Reinforced Functions to Concrete: compared with steel fiber, full-dispersed polypropylene fiber has advantages in its thinness, large amount, non-water absorbency, strong acid & alkali resistance and similar elastic modulus with that of concrete.

The reinforced functions run as follows:

◆Increase seepage resistance

◆Prolong endurance

◆Improve steel protection

◆Increase cracking resistance

◆Increase fire resistance

◆Strengthen spurt & fatigue

◆Improve tensile, bending & folding strength

◆Improve plastic deformity

◆Strong acid & alkali resistance and good endurance

Application

- Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance.

- The wall of tunnels, mines, roofs and reservoir projects with special construction.

- River courses and dams, etc.

- Military defense works, dock banks and piers, etc.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible