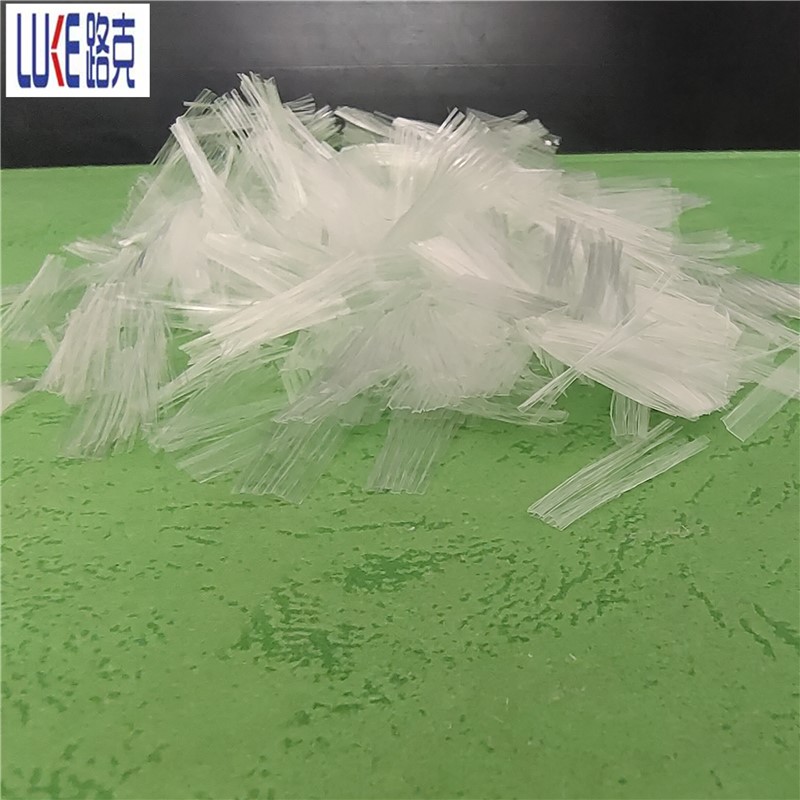

Polypropylene Fiber PP Mesh Fiber For Shotcrete

Polypropylene fiber pp mesh fiber shotcrete is higher in strength,and better in crack-resistance and anti-deformation performance.

Polypropylene mesh fiber add in concrete can greatly reduce resilience and reduce costs.

Polypropylene pp mesh is an ideal concrete additive.

Polypropylene is resistant to acid and alkail and corrosion.

Samples:

Maximum order quantity:1kg

Polypropylene Fiber pp mesh fiber For Shotcrete

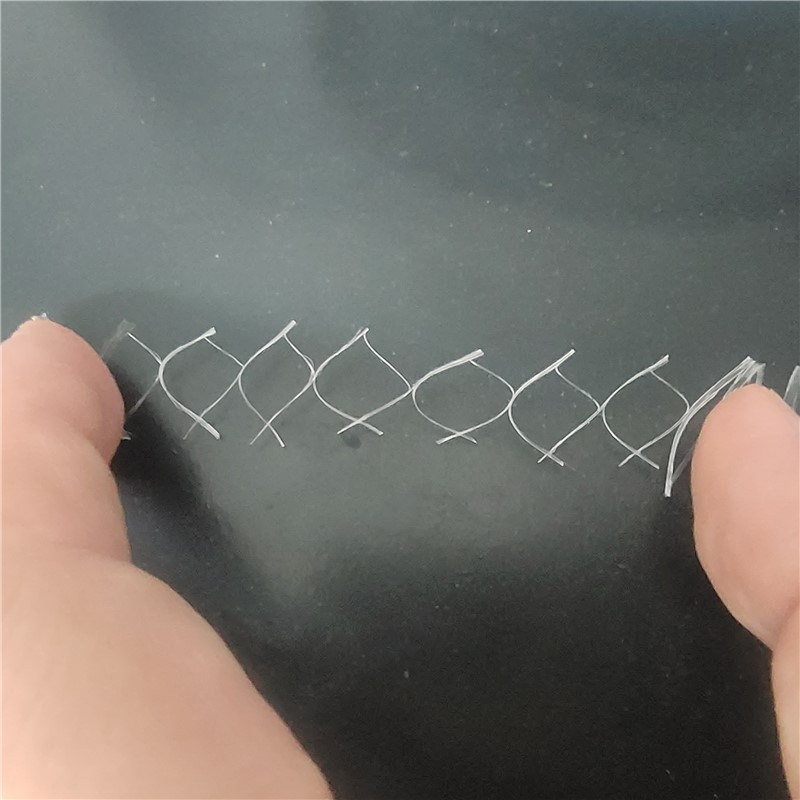

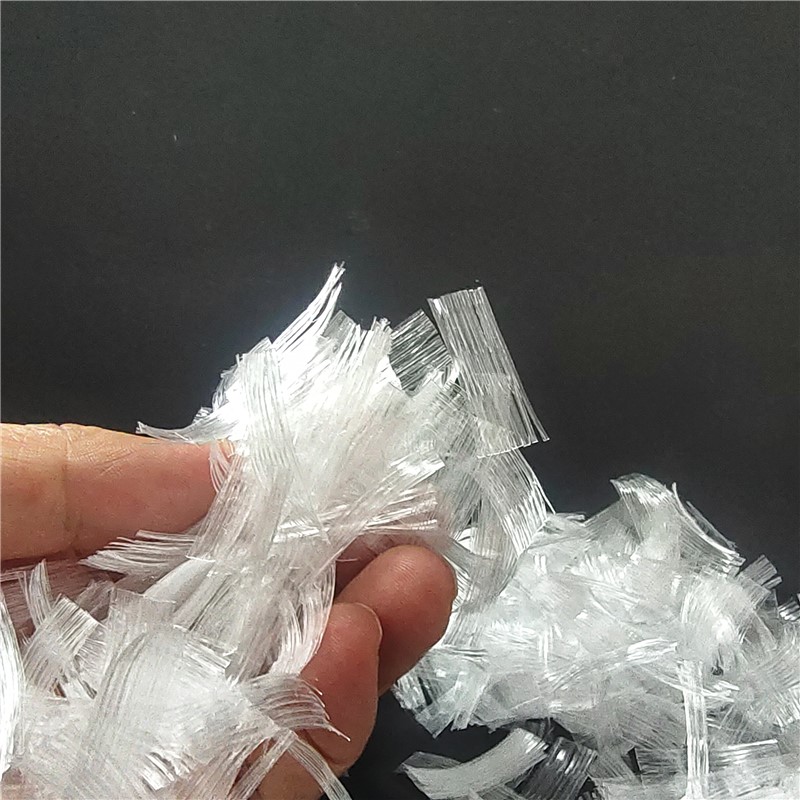

Polypropylene fiber Mesh Fiber is also known as Polypropylene fiber mesh(PP fiber- mesh).

The compressive and flexural strength of polypropylene fiber shotcrete is higher than that of ordinary shotconcrete, and it can prevent the shrinkage and cracking and enhance the cracking resistance and toughness of concrete.

Polypropylene fiber shotcrete is easier to pump and has less wear and tear on equipment.

The construction process of polypropylene fiber shotcrete is simple, and it does not need to add equipment compared with ordinary concrete.

Under the same strength condition, polypropylene fiber shotcrete can reduce the thickness of shotcrete layer, greatly reduce the rebound of concrete and reduce the cost. As long as the rational use, can play a considerable technical and economic benefits, has a wide range of application prospects.

Polypropylene pp mesh fiber shotcrete technical parameters:

Raw Materia | 100%Polypropylene | Length(mm) | 19、25、38 |

Trademark | LUKE | Tensile Strength | >450(MPa) |

Origin | China | ElasticModulus | ≥3500(MPa) |

Shape | Net-like Beam | Equivalent Dia | 100±50 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥10% |

Color | White | Melting Piont | 160-170℃ |

Resistance Acid alkali | Strong | ||

Applying instruction of polypropylene mesh fiber:

1、The choices of polypropylene PP fiber mesh length:Generally,the length of polypropylene pp mesh fiber in engineering concrete is 20mm.

2、The amount of polypropylene mesh fiber is 0.9KG, and the amount of waterproof layer on the bridge floor is 1.8KG, and the amount of other materials is not changed. When there are special uses, the amount of polypropylene mesh fiber can be determined by testing.

3、Mixing process:crusted stones,fibers and sands are put into the mixer in succession.After stirring for two minutes,fiber will fully spread and then add cement and water and stir normally.The addition of materials also can be put into as usual,but the stirring time should be properly prolonged to more than 4 minutes make fiber completely mixed.

4、Mixer:Horizontal Two-shaft Forced Mixer.

Packaging with polypropylene pp fiber concrete fibers:

1、Carton Packing

2、Polypropylene fiber concrete fiber woven bag packaging:

Packaging of polypropylene fiber pp fiber for sprayed concrete:

1、Common 0.9 or 1Kg per bag,may packed as customer’s requirement.

2、You can choice carton,paper bag,woven bag,paper bag or water solube bag,paller

3、Special packaging can be supplied on your need.

The use of polypropylene fiber pp mesh fiber:

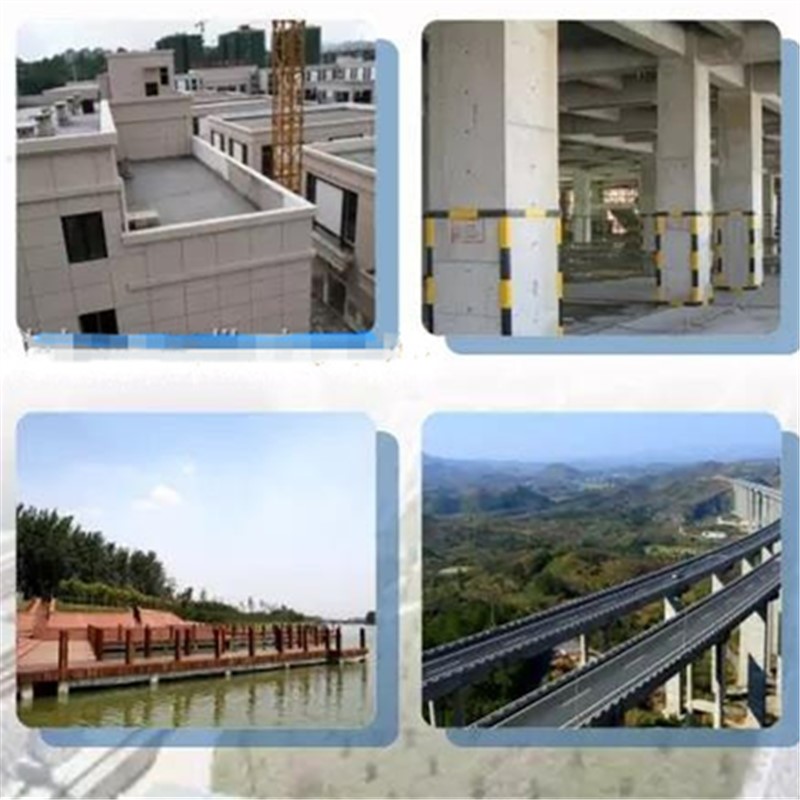

1、Engineering requiring high crack resistance, such as concrete pavement, bridge deck, airport runway, factory horizo, shortcrete projects.

2、Such as tunnel,mine wall,roof,reservoir and other projects using special construction methods.

3、Irrigation work such as river,dam

4、Polypropylene pp fiber concrete fiber can be used for military protection,terminal revetment,bridge pier

5、polypropylene pp fiber mesh is suit for concrete precast.

Our commitment:

Professional equipment, high quality polypropylene concrete fibers, first-class service is your best choice,welcome to our company!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible