Durability Of Polypropylene Fiber Reinforced Concrete

100 % Pure Polypropylene

Good Dispersion

High Tensile Strength

Best for Concrete Reinforcement

One-stop Service,Strict Quality Control

Durability Of Polypropylene Fiber Reinforced Concrete

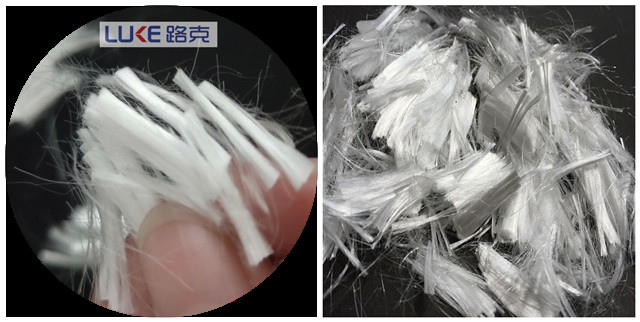

Polypropylene (pp) is a semi-crystalline thermoplastic.

Using fiber-grade polypropylene as the raw material, it is a high-power package deal-fashioned mono-filament organic fiber

shaped by means of a special method.

Its inherent sturdy acid resistance, strong alkali resistance, vulnerable thermal conductivity, and extremely solid chemical homes.

Polypropylene fiber is also known as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber.

We use excessive tenacity polypropylene resin because the uncooked material and produce with unique technical.

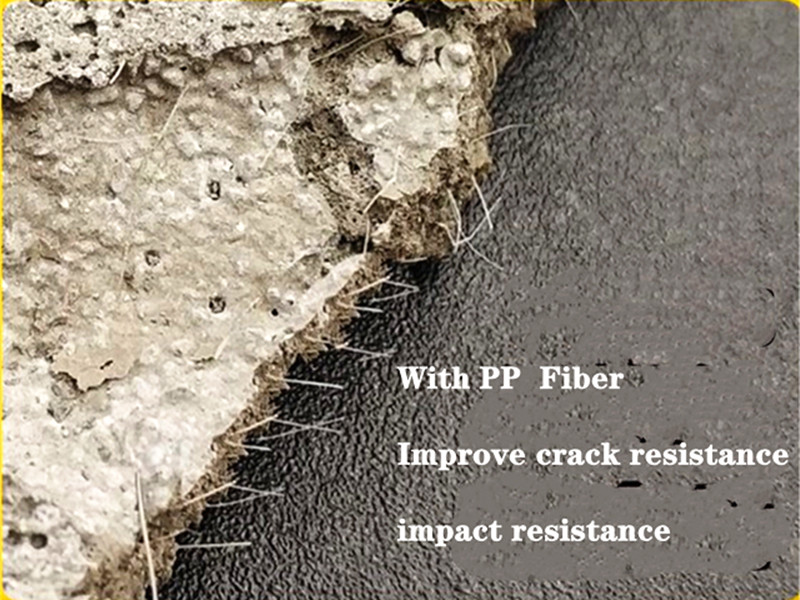

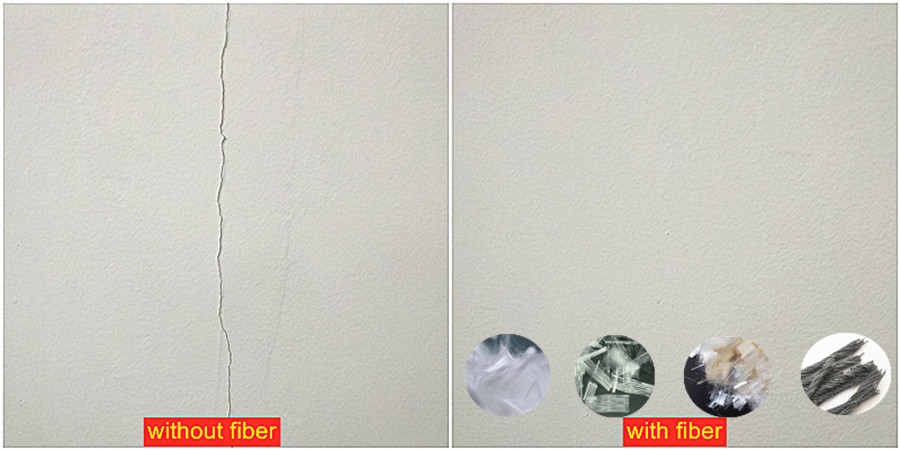

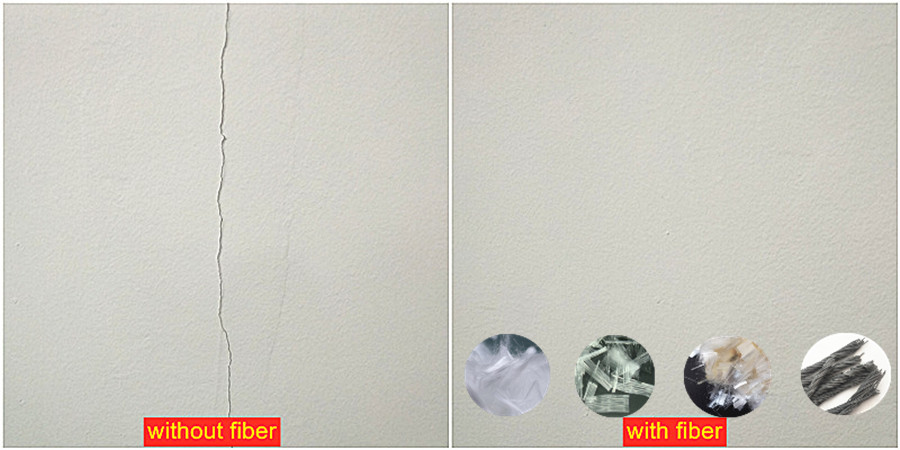

Setting the pp fiber into concrete or mortar can control the micro crack because of the plasticity contraction, air shrinkage and

temperature change.

Parameter

Raw Material | Polypropylene | Fiber Type | Monofilament |

Crack Elongation(%) | ≥15 | Elasticity Modulus (Mpa) | ≥3500 |

Density(g/cm³) | 0.91-0.93 | Fiber Diameter | 25-45μm |

Tensile Strength(Mpa) | 500 | Melting Point | 160-170℃ |

Acid &Alkali Resistance | strong | Water absorbency | NO |

Normal Length(mm) | 4mm,6mm,10mm,12mm,19mm or as your request | ||

Feature

1.Improving the ability of concrete to resist earthquake and natural disasters

2.Improving crack resistance of concrete

3.Reduces plastic shrinkage and settlement cracking

4.Increase the wear resistance of concrete

5.Improving the capacity of concrete to protect steel

6.Increasing the concrete crack resistance, flexural strength

Application

1. Be suitable for the water–proof layer, floor, inner & outer wall of industrial and civil construction.

2. Increase cracking resistance on the surface of industrial workshop, warehouse and parking lot.

3. Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch.

4. Be suitable for any mortar projects and fine aggregate concrete projects.

High demand projects

1. PP fibers for concrete are suitable for concrete rigid self-waterproof structure and high-demand projects to longer the service life.

2. Basement floor, sidewall, roof, roof cast-in-place slab, reservoir, water conservancy projects, subways, airport runways,

port terminals, overpass viaduct decks, piers, super-long structures.

Cement motar

1. PP fiber can reduce cracks in the cement mortar.

2. Internal (external) wall painting, aerated concrete plastering, interior decoration putty, thermal insulation mortar.

3. Polypropylene fibers are applied to anti-explosion and fire-resistant engineering with its high ignition point.

Company Information

Shandong Luke Composite Co., Ltd is professional manufacturer of Synthetic Fibers.

We are located in Tai'an city, and we uphold unity, hard working, enterprising spirit, credibility, cooperation and

win-win business philosophy, to meet market demand as the core, to provide our best quality products for our

customers and friends.

We have established long-term and stable local and overseas customers, the products have been exported to

the Middle East, Africa, Southeast Asia, South America, Australia, Europe etc.

and provide customers with a satisfactory pre-sales guidance and after-sales service work.

A: T/T 30% as deposit, and 70% before shipping the goods.

Q2. How about your delivery time?

A: Generally, it will take 3 to 7 days after receiving your advance payment.

Q3. Can you produce according to the samples?

A: Yes, we can produce by your samples or detailed requirement.

Q4. What is your sample policy?

A: We can supply free sample for testing, the customers just pay for the freight.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible