China Manufacturer Polypropylene Twisted Fiber For Concrete

PolypropyleneTwisted fiber for concrete have many excellet characteristics in cement engineering . Include high breaking strength, good dispersion in concrete, and strong bond stress.

Tensile Strength:>450Mpa

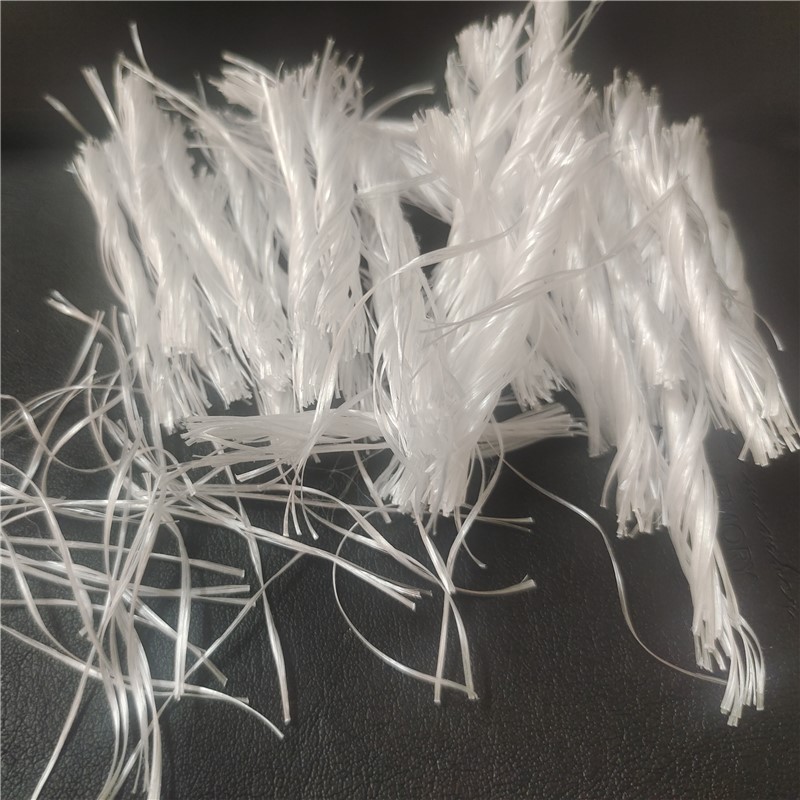

Product shape:Twisted Boundle

Elastic Modulus:>4000Mpa

China Manufacturer Polypropylene Twisted Fiber For Concrete

Overview of china manufacturer polypropylene twisted fiber:

China manufacturer polypropylene twisted fiber for concrete is a synthetic with high strength and good physical and chemical properties. Polypropylene twisted fiber is made of 100% polypropylene and deep processing through special processing, wire drawing technology and surface treatment.It has lots of advantages in construction engineering.

Characteristics of polypropylene twisted fiber for concrete compared with steel fiber:

1、Good dispersion: The dispersion performance of polypropylene twisted fiber in concrete is excellent, which helps to improve the uniformity and stability of concrete.

2、Strong grip and wrapping force: the polypropylene twisted fiber has good grip and wrapping force, which can enhance the structural strength and durability of concrete.

3、It has advantages of acid,alkali resistant.

4、High elastic modulus: >4000Mpa.The high elastic modulus of twisted fiber helps to improve the toughness and impact resistance of concrete.

5、Easy to disperse and easy to construct: The special design of twisted fiber makes its dispersion and construction process in concrete simple, and there is no damage to the mixing equipment.

6、High breaking strength: It has high breaking strength, which can improve the crack resistance of concrete.

Technical parameter with Polypropylene Twisted Fiber For Concrete:

Density(g/cm³) | 0.91 |

Length(mm) | 30~70 |

Color | Black/Grey/White |

Shape | Twisted bundle |

Tensile Strength(MPa ) | >450 |

Elastic Modulus(MPa ) | >4000 |

Equivalent Dia(mm) | 0.3±0.05 |

Crack Elongation(%) | ≥15 |

Piont | 160℃ |

Material | 100%Polypropylene |

Lead time of Polypropylene twisted fiber for concrete:

Quantity(kilograms) | 1-10000 | 10001-20000 | >20000 |

Lead time (days) | 10 | 14 | To be negotiated |

Applying Instruction with China Manufacturer Polypropylene Twisted Fiber For Concrete:

1、Stirring requirment:crusted stones,fibers and sands are put into the mixer in succession.After stirring for 2 mintues,fiber will fully spread and then add cement and water and stir normally.The addition of materials also can be put into as usual ,but the stirring time should be properly prolonged to more than 4 mintues to make fiber completely mixed.

2、Package:1/kg per bag,may packed according to ratio with PP Fiber mesh.

3、Dosage:no less than 3kg/cubic meter of concrete for high crack level(volume ratio:0.3%);for general level,it can use compound fiber of 0.8kg twisted bundle PP fiber and 0.4kg PP fiber mesh.

Polypropylene twisted fiber is widely used in concrete engineering :

Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch

Improve the crack-resistance in large scale of cement concrete for industrial workshop,warehouse,parking lot ,airport,underground engineering,Hydraulic work ect.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible