PP Engineering Fiber Effectively Improves Concrete Reinforcement

100 % Pure Polypropylene

Good Dispersion

High Tensile Strength

Best for Concrete Reinforcement

One-stop Service,Strict Quality Control

PP Engineering Fiber Effectively Improves Concrete Reinforcement

Product Details

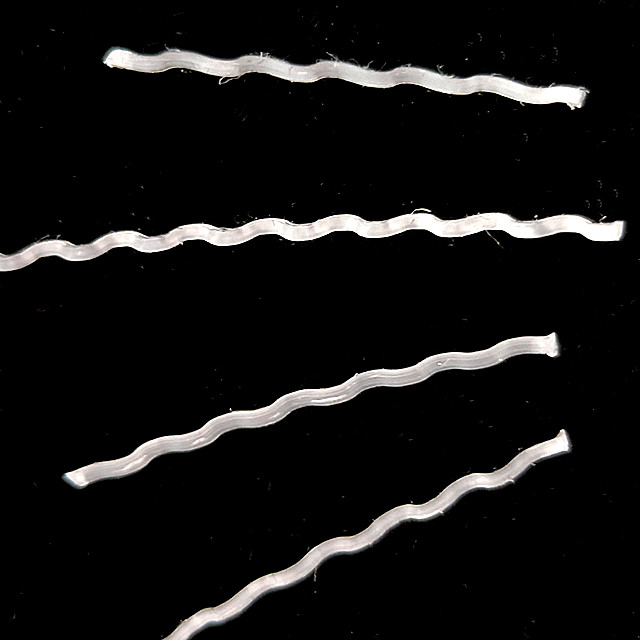

With polypropylene fiber as its uncooked cloth, curved pp macro fiber is produced by using unique molding system and floor

change;It has benefit of acid, alkali resistant, awesome tensile, easy dispersing, comfort for creation and no harm to automobiles

and pavement and no want for special conservation.

Curved pp macro fiber can be used rather than metallic fiber to beautify the crack resistance of cement concrete and notably

improve the toughness and flexural of concrete.

Due to unique shape, curved pp macro fiver has appropriate aggregate with concrete and robust bond.

Parameter

Density(g/cm³) | 0.91 | Elastic Modulus(Mpa) | >4000 |

Length(mm) | 36,48,54mm | Equivalent Dia(mm) | 0.9±0.2 |

Color | White or black | Crack Elongation(%) | ≥15 |

Shape | Curved/wave | Melting Point | 160-170 ℃ |

Tensile Strength(Mpa) | ≥ 450Mpa | Resistance Acid alkali | Strong |

Applying Insturction

1) Dosage: more than 3kg/cubic meter of concrete.

2) Length: 36mm for general crack level,

3) Mix design: In general, no need change the ratio parameters of concrete.

Considering the concrete anti-cracking performance requirements, can add 0.9 kg monofilament fiber per square concrete.

4) Instructions: crushed stones, fibers and sands are put into the mixer in succession.

The addition of materials can be put into as usual,

but the stirring time should be properly prolonged to more than 4 minutes to make fiber completely mixed.

5) Forming conservation: Conservation can be based upon the requirement of ordinary concrete.

Feature

1,Can reduce damage when happened earthquakes and other natural disasters.

2,To reduce fatal flaws in concrete

3,To reduce the leakage of concrete

4,To protect steel from corrosion

5,To improve the durability of concrete structures

6,Increase the wear resistance of concrete

7,Increasing the concrete crack resistance, flexural strength, increased toughness of concrete, to extend the life of concrete binder

Application

• Slab on Grade and elevated construction (distribution centers, warehouses, etc.)

• Thin walled pre-cast (septic tanks, vaults, walls, etc.)

• Shotcrete for tunnel linings, pool construction and slope stabilization

• Pavements and white-toppings

FAQ

Q: How long is your delivery time?

A: Generally it is 7-15 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ?

Is it free or extra ?

A: Yes, we could offer the sample within 1kg for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible