Polypropylene Monofilament Micro PP Fiber For Building

Polypropylene micro fiber can reduces plastic shrinkage cracking.

PP monofilament micro pp fiber for building as a engineering fiber can be used in highly corrosive circumstance.

Polypropylene synthetic fiber has strong tensile strength.

Polypropylene pp micro fiber is widely used in buildings,which is easy disperse,can save costs,convenient construction and simple operation.

Concrete polypropylene fiber can reduce water seepage and extend the building life.

Polypropylene Monofilament Micro pp fiber For Concrete

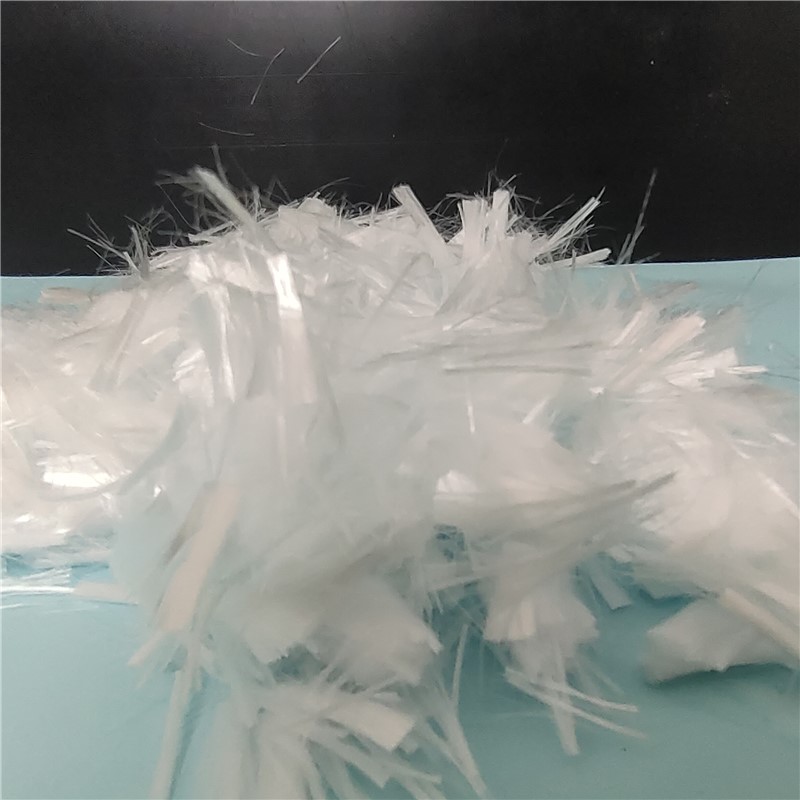

Building special PP monofilament fiber is also called synthetic fiber, engineering fiber, concrete fiber, anti-crack fiber, and so on.It is a kind of high strength bundle monofilament fiber synthesized from polypropylene as the main raw material.Adding cement concrete or mortar can effectively control the concrete mortar due to plastic shrinkage,dry shrinkage,temperature change and other factors caused by micro-cracks,prevent and inhibit the formation and development of cracks,greatly improve the concrete crack resistance and anti-seepage perfomance,impact resistance and earthquake resistance of concrete.

Technical parameter of concrete polypropylene micro fiber:

Raw Materia | 100%Polypropylene | Length(mm) | 3~19 |

Trademark | LUKE | Tensile Strength | >560(MPa) |

Origin | China | ElasticModulus | ≥3000(MPa) |

Type | Monofilament | Fiber Diamater | 25~45um |

Density(g/cm³) | 0.91~0.93 | Crack Elongation | 15% |

Color | Natural(White) | Melting Piont | 160-170℃ |

Applying instruction for the use of polypropylene fiber in concrete cement mortar:

1、Choice of polypropylene fiber length:

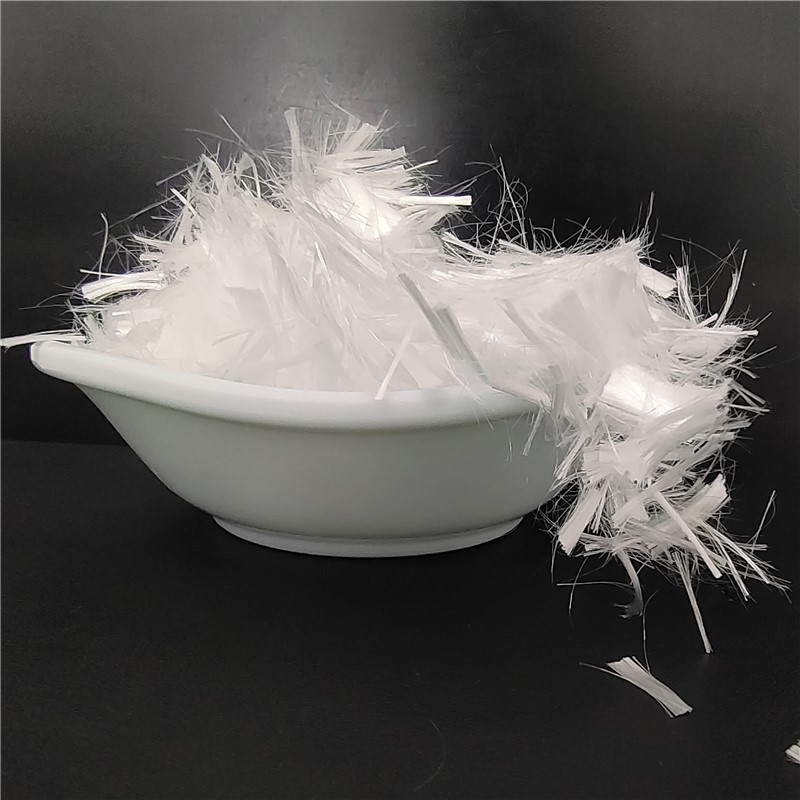

Fine aggregate concrete such as mortar is suitable for polypropylene micro fiber length less than 12mm, and coarse aggregate concrete is suitable for concrete above 12mm.

2、Compounding Amount:for resisting the common cracks on surface,0.9kg/m ³fibers to cement mortar are enough.

3、Ratio and mixing requirements:the proportion of cement,sand and aggregate is no need to be changed.Put cement,aggregate,additive and the polypropylene fiber(pp monofilament micro fiber or pp macro fiber) together,then stir after adding enough water and time for stirring can be prolonged for 2-3 minutes in order to make the compound mix completely.Also the Polypropylene fibers can be mixed even with cement and other aggregates in advance,striring by adding water at worksite before constructing.

Polypropylene fibers(pp monofilament micro fiber or polypropylene macro fiber or twised bundle pp fiber) packaging:

You can choose any kind of packaging such as cartons,oppbag,paper bag, warter soluble packing,poly bag,woven bag,pallet,etc.Or customized accroding to your needs.

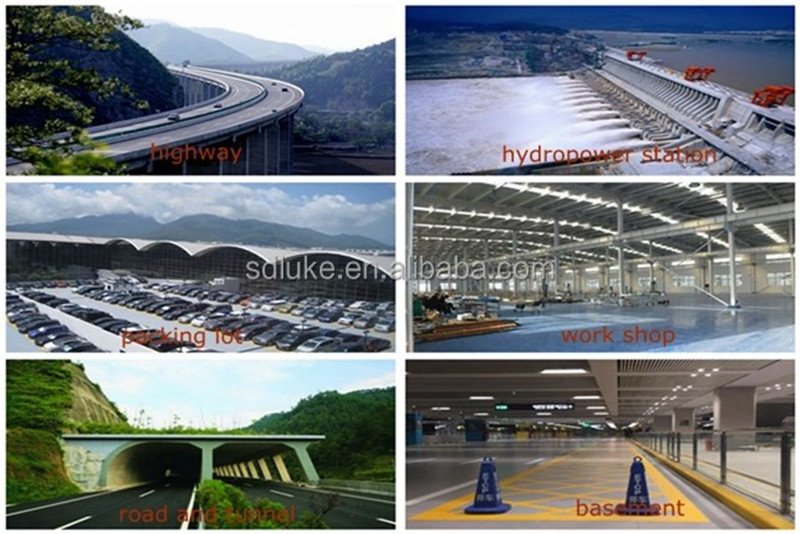

Application of concrete polypropylene monofilament micro pp fiber:

Construction fiber is suitable for all types of concrete projects,including buildings,bridges,roadways and water conservancy projects.

Polypropylene monofilament micro pp fiber be suitable for the water-proof layer,floor,inner&outer wall of industrial and civil construction.

Increase cracking resistance on the surface of industrail workshop,warehouse and parking lot.

Increase cracking&seepage resistance of the ground in natatorium,swimming pool,pond and ditch.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible