Benefits Of Polypropylene Micro Fiber Reinforced Concrete

100 % Pure Polypropylene

Good Dispersion

High Tensile Strength

Best for Concrete Reinforcement

One-stop Service,Strict Quality Control

Benefits Of Polypropylene Micro Fiber Reinforced Concrete

Polypropylene (PP) is a semi-crystalline thermoplastic.

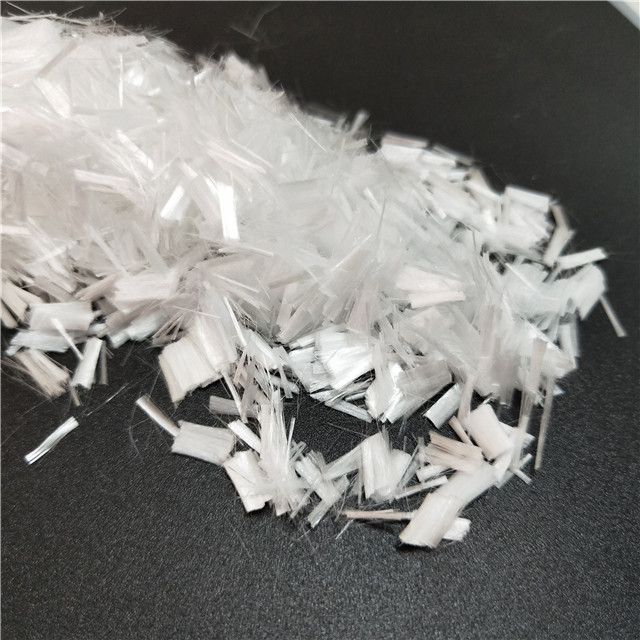

Using fiber-grade polypropylene as the raw material, it is a high-strength bundle-shaped mono-filament organic fiber formed

by a special process.

Its inherent strong acid resistance, strong alkali resistance, weak thermal conductivity, and extremely stable chemical properties.

Polypropylene Fiber is also called Engineered Fiber,Concrete Fibers,is made by 100% new polypropylene.It has good

dispersion,high tensile strength,mainly used in concrete reinforcement,anti-crack,construction etc.

Parameter

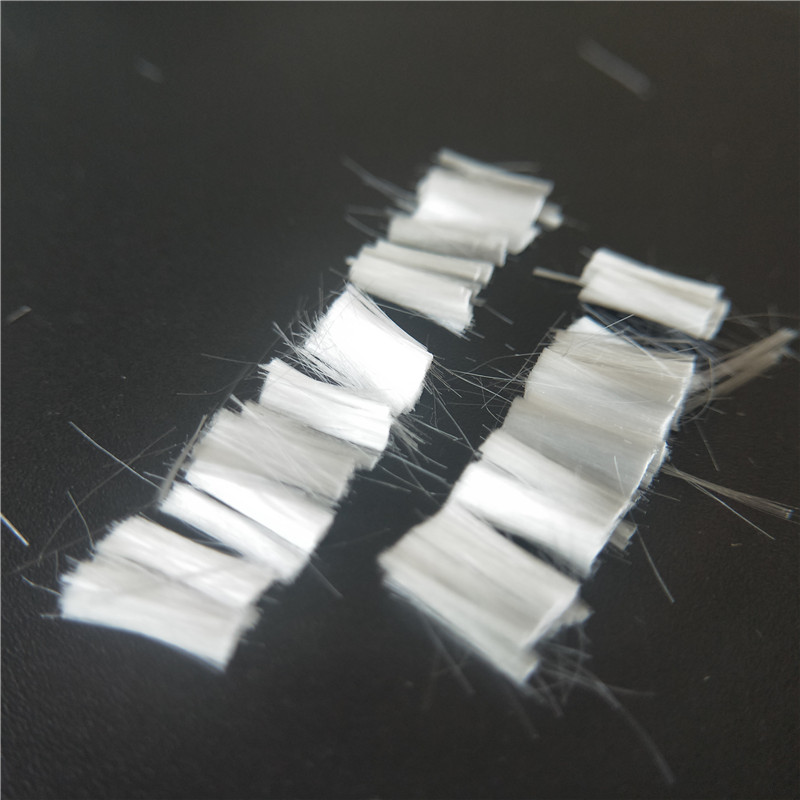

Raw Material | Polypropylene | Fiber Type | Monofilament |

Crack Elongation(%) | ≥15 | Elasticity Modulus (Mpa) | ≥3500 |

Density(g/cm³) | 0.91-0.93 | Fiber Diameter | 25-45μm |

Tensile Strength(Mpa) | 500 | Melting Point | 160-170℃ |

Acid &Alkali Resistance | strong | Water absorbency | NO |

Normal Length(mm) | 4mm,6mm,10mm,12mm,19mm or as your request | ||

Feature

1.Improving the ability of concrete to resist earthquake and natural disasters

2.Improving crack resistance of concrete

3.Reduces plastic shrinkage and settlement cracking

4.Increase the wear resistance of concrete

5.Improving the capacity of concrete to protect steel

6.Increasing the concrete crack resistance, flexural strength

Application

1. Be suitable for the water–proof layer, floor, inner & outer wall of industrial and civil construction.

2. Increase cracking resistance on the surface of industrial workshop, warehouse and parking lot.

3. Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch.

4. Be suitable for any mortar projects and fine aggregate concrete projects.

Length: for motor: <12 mm;

Compounding amount: for resisting the common cracks on surface, 0.9 kg/ m³ fibers to cement mortar are enough.

Stirring requirement: the proportion of cement, sand and aggregate is no need to be changed.

Put cement, aggregate, additive and fiber together, then stir after adding enough water and time for stirring can be

Also it can be mixed even with cement and other aggregates in advance, stirring by adding water at work-site before

100% Raw material+Advanced equipment+Strict quality inspection+Excellent packaging

= High Quality Product and Good Service

Company Information

Shandong Luke Composite Co., Ltd is professional manufacturer of Synthetic Fibers.

We are located in Tai‘an city, and we uphold unity, hard working, enterprising spirit, credibility, cooperation and win-win

business philosophy, to meet market demand as the core, to provide our best quality products for our customers and

friends.

-------Polypropylene Micro Fiber

-------Polypropylene Macro Fiber

-------Polypropylene Mesh Fiber

-------Polypropylene Twist Fiber

-------Polypropylene Micro Copper Coated Steel Fiber

-------PVA Fiber

-------Glass Fiber

We have established long-term and stable local and overseas customers, the products have been exported to

the Middle East, Africa, Southeast Asia, South America, Australia, Europe etc.

Welcome to visit our company!

Any question please kindly feel free to contact us,waiting for your inquiry.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible