PP Staple Fiber Needled Non-woven Geotextile

High strength and wear resistance:

The main raw materials of staple fiber needled non-woven geotextiles are high-strength synthetic fibers, which makes it have high tensile strength and wear resistance.

Can be used for a long time under heavy load conditions.

It has good water seepage performance.

Staple fiber needled non-woven geotextile has high density, low porosity, good waterproof and impermeability, and can effectively prevent water penetration.

PP Staple Fiber Needled Non-woven Geotextile

Staple fiber geotextile non-woven are materials made of chemical staple fibers. Specifically, staple fiber non-woven geotextile are non-woven materials made of polyester or polypropylene staple fibers through a series of processes such as mixing, carding, mesh molding, needling, etc.

PP staple fiber geotextile is called non woven polypropylene geotextile, which is produced from polypropylene fiber by different equipment and technology to get different thickness.

The feature of PP geotextile non woven:

◆High strength and wear: The main raw materials of staple fiber needled non-woven geotextiles are high-strength synthetic fibers, such as polyester and polypropylene, which makes it have high tensile strength and wear resistance.

◆Good water permeability: with gaps between fibers,so it has good water permeability.

◆The material is light and soft,it is convenient to transport,lay and construction.

◆Corrosion resistance and oxidation resistance : This geotextile has good corrosion resistance, can be in different pH of soil and water for a long time corrosion resistance.

PP staplefiber needle punched geotextile non woven technical parameter:

Test Properties | Units | LKS10 | LKS15 | LKS20 | LKS25 | LKS30 | LKS35 | LKS40 | LKS45 | LKS50 | LKS60 | LKS80 | |

Mechanical Properties | Weight | g/㎡ | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

Weight Variation | % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

Width Variation | % | 0.5 | |||||||||||

Break Strength(MD and XMD) | kN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 | |

Break Elongation | % | 25-100 | |||||||||||

CBR Burst Strength | |||||||||||||

Tear Strength≥(MD and XMD) | kN | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | |

Hydraulic Properties | Sieve SizeO90 | mm | 0.07-0.20 | ||||||||||

Coefficient of Permeability | Cm/s | (1.0-9.9) ×(10-1-10-3) | |||||||||||

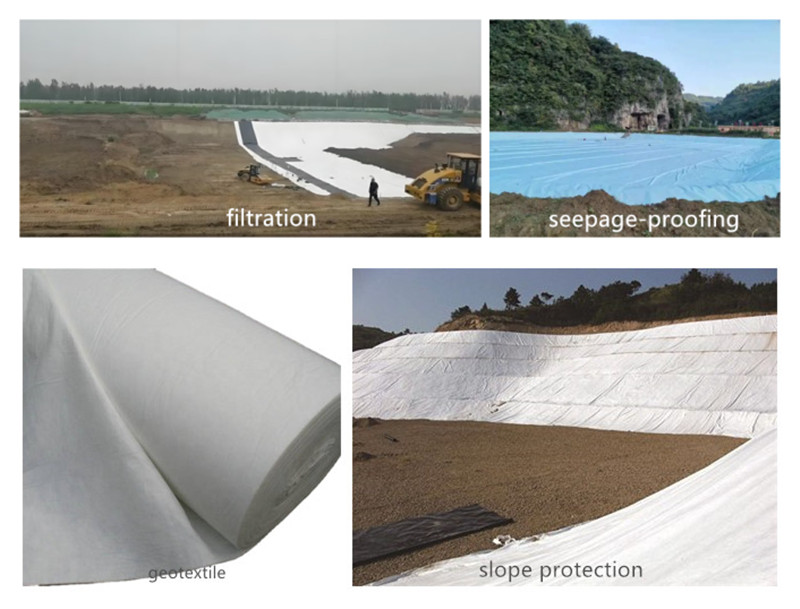

The main function of PP punched geotextile:

The main function is filtration ,drainage, reinforcement.

It has good impermeability and resistance to deformation.

Packaging and delivery:

Woven bag in roll or customer’s requirements.

Size of package: Width 2-6m, length 50-100m or as customer request.

About our after-sales service:

Our company provides a one-stop service, and our technical staff provides 24/7 online support to solve any technical problems related to non-woven PP geotextile in a timely manner. Thank you for your love of our products.

Application:

◆Reinforcement in retaining wall backfill.

◆Strengthen the weak road and fix the cracks on the road.

◆Improve the stability of slope and reinforcement soil,avoid water and soil loss and soil frozen in jure.

◆Isolation layer of drainage pipe or gravel sub-drain.

◆Vertical or horizontal drainage, bury in soil to release air pressure.

◆Reinforcement the weak foundation of engineering of road,railway,embankment,airport.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible