LUKE Polypropylene Mesh Fiber For Concrete

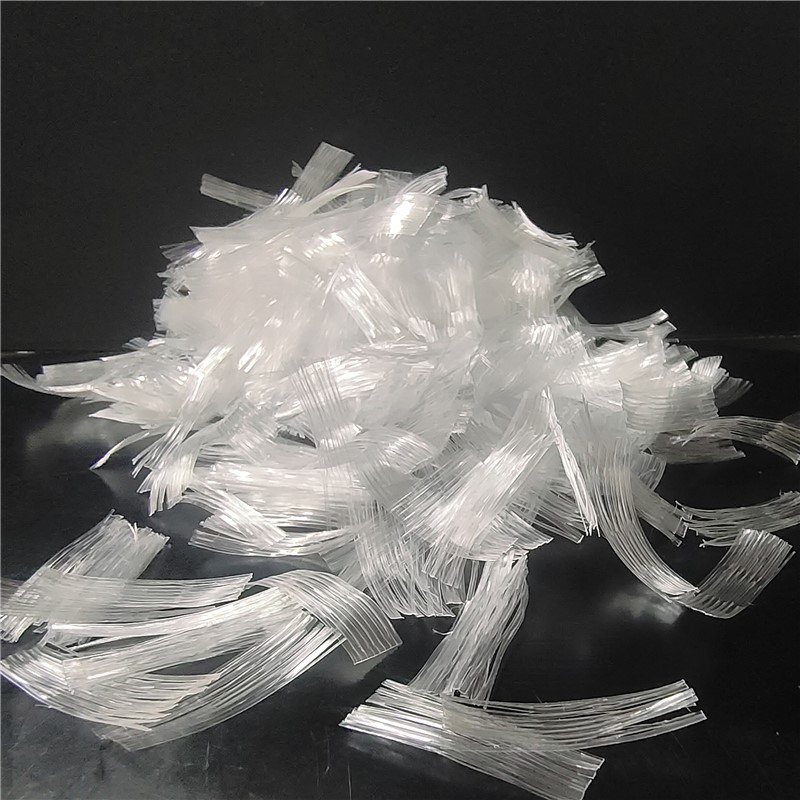

Fibrillated Mesh Polypropylene Fibre for Concrete Reinforcement

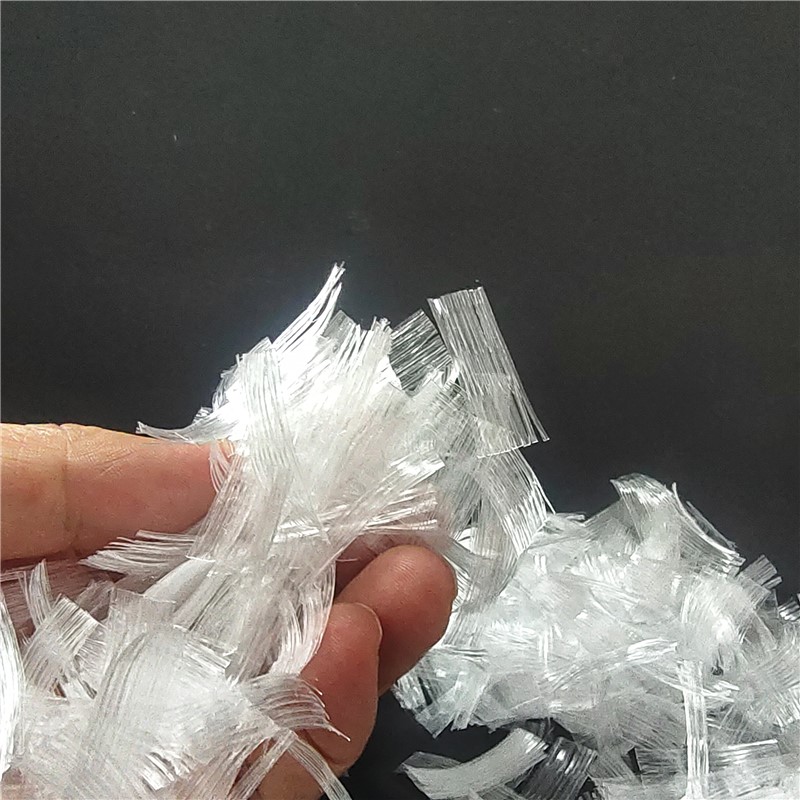

The polypropylene fibers are in a network shape,which can increase the tensile Strength

It has good acid and alkali resistance.

Concrete pp fiber mesh can resist to shrink and crack.

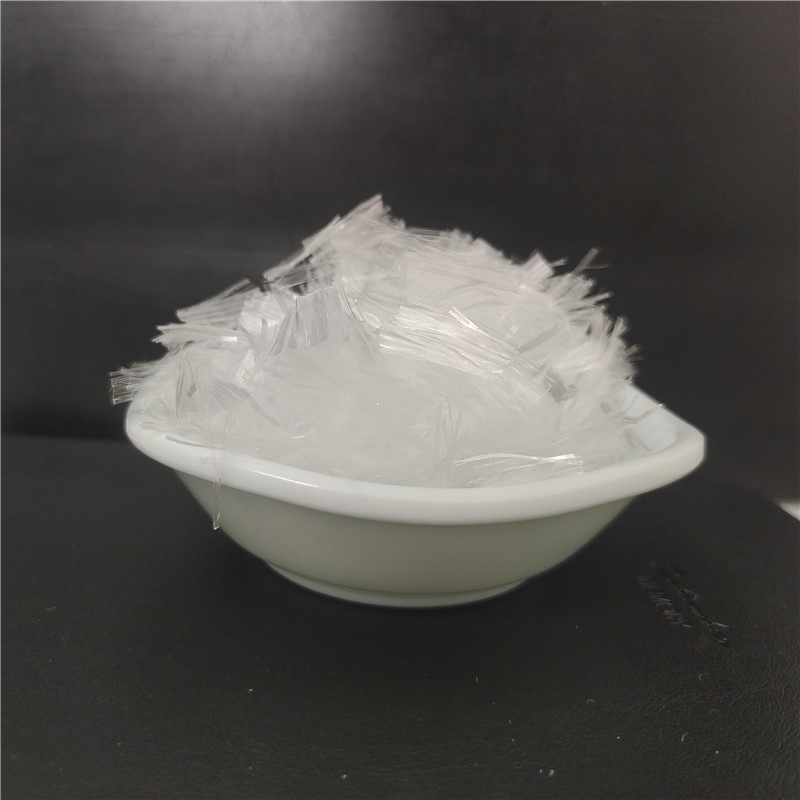

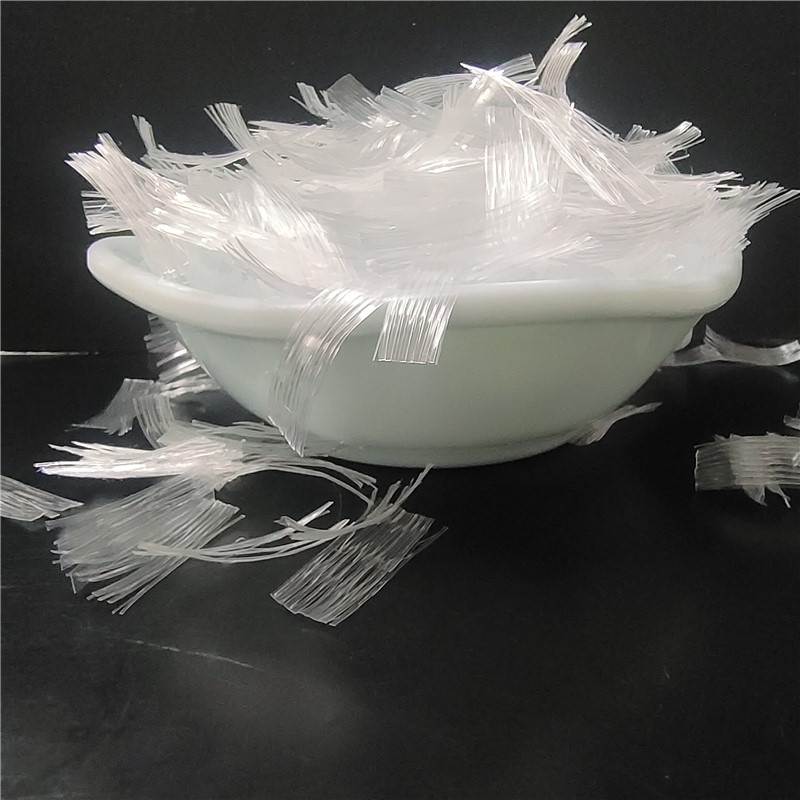

Construction is convenient and easy to disperse.

LUKE Polypropylene Mesh Fiber For Concrete

Shandong Luke Composite Co., Ltd. is located at the foot of the beautiful Mount Tai. We now mainly produce and sell concrete anti-cracking fiber, anti-seepage geotechnical materials. Concrete anti-cracking fibers mainly include:polypropylene pp fiber, polypropylene PP mesh fiber, PAN fiber,high strength and high modulus polyvinyl alcohol fiber(PVA fiber),water-soluble PVA fiber, imitation steel fiber, polypropylene twisted bundle pp fiber,curved pp macro fiber, steel fiber, etc. Geotechnical materials are: geotextiles, geomembrane,HDPE film.

Technical parameters with polypropylene mesh fiber:

Raw Materia | 100%Polypropylene | Length(mm) | 6、19、25、38 |

Trademark | LUKE | Tensile Strength | >450(MPa) |

Origin | China | ElasticModulus | ≥3500(MPa) |

Shape | Net-like Beam | Equivalent Dia | 100±50 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥10% |

Color | White | Melting Piont | 160-170℃ |

Resistance Acid alkali | Strong | ||

The characteristic of polypropylene pp mesh fiber concrete fiber:

PP fiber mesh can improve the uniformity of concrete.

Improve the fire resistance of concrete.

Reducing brittleness of high strength concrete.

Improve freezing and earthquake resistance of buildings.

Improving the impact resistance ,wear resistance of concrete.

Test and analysis results indicate that mixing fiber into road concrete can decrease the brittleness and promote the flexural strength and abrasion resistance.

Applying instruction of polypropylene mesh fiber:

1、the choices of polypropylene pp fiber mesh length:Generally,the length of polypropylene pp mesh fiber in engineering concrete is 20mm.

2、the amount of polypropylene mesh fiber is 0.9KG, and the amount of waterproof layer on the bridge floor is 1.8KG, and the amount of other materials is not changed. When there are special uses, the amount of polypropylene mesh fiber can be determined by testing.

3、Mixing process:crusted stones,fibers and sands are put into the mixer in succession.After stirring for two minutes,fiber will fully spread and then add cement and water and stir normally.The addition of materials also can be put into as usual,but the stirring time should be properly prolonged to more than 4 minutes make fiber completely mixed.

4、Mixer:Horizontal Two-shaft Forced Mixer.

My company's polypropylene fibers(pp macro fiber,pp micro fiber,pp fiber mesh,twsisted bundle pp fiber) packaging:

The polypropylene fiber concrete fiber primary application:

1、Engineering requiring high crack resistance, such as concrete pavement, bridge deck, airport runway, factory horizo, shortcrete projects.

2、such as tunnel,mine wall,roof,reservoir and other projects using special construction methods.

3、 irrigation work such as river,dam.

4、 Polypropylene PP fiber concrete fiber can be used for military protection,terminal revetment,bridge pier.

5、Polypropylene pp fiber mesh is suit for concrete precast.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible