Concrete Polypropylene Monofilament Micro Fiber

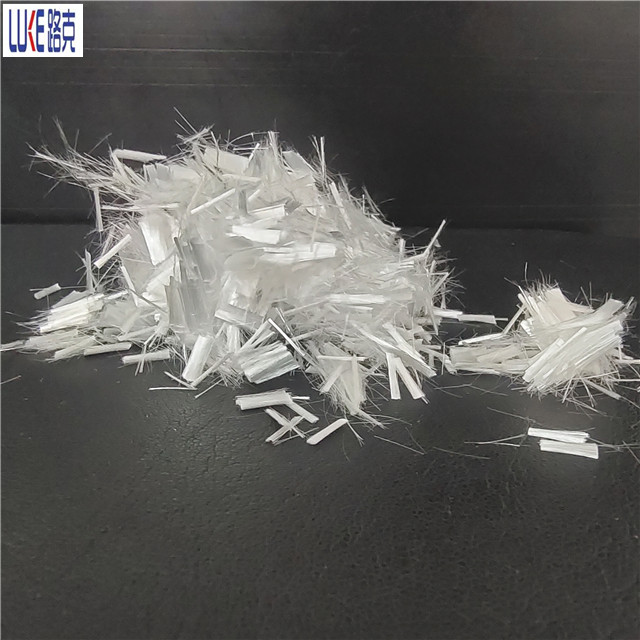

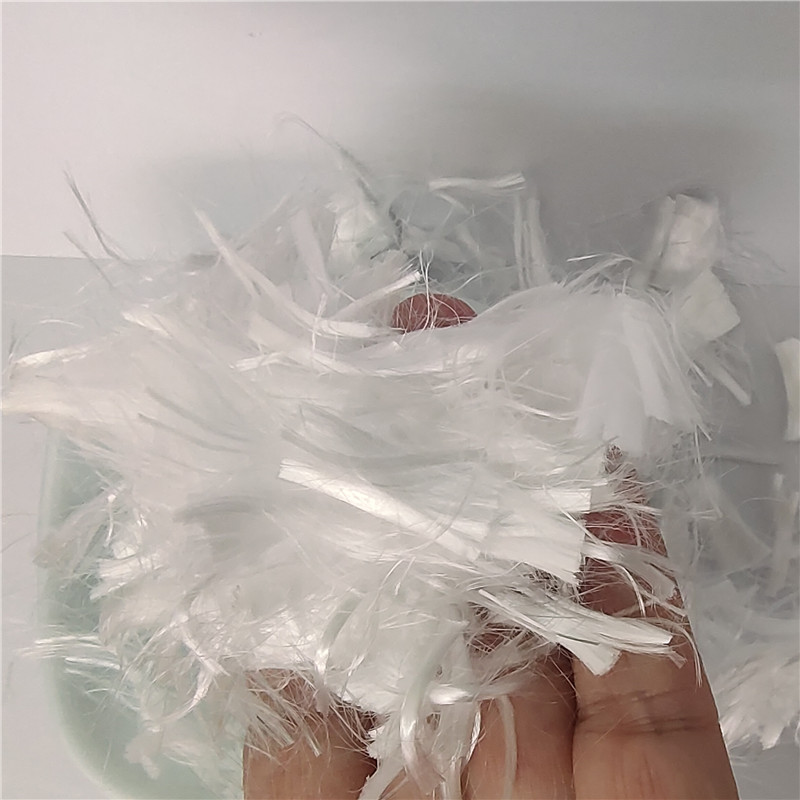

PP fiber is a 100% polypropylene as its material.

Polypropylene has excellent physical, chemical and mechanical properties.

Polypropylene has the characteristics of low cost and easy processing.

Polypropylene has impact resistance.

I t can resistance of acid and alkail.

Concrete Polypropylene Monofilament Micro Fiber

Concrete Polypropylene Monofilament Micro Fiber has high tensile strength original modulus and good tenacity. Therefore, it can withstand large loads and tensile strains. Adding polypropylene microfiber to concrete or mortar can effectively control the microcracks caused by plastic shrinkage, temperature and other factors. And greatly improve the concrete cracking resistance, leakage resistance, impact resistance, seismic performance.It is a new type of toughening and cracking prevention material used in construction.

PP micro fibers function and benefits:

◆Stable performance, safe and harmless.

◆Effective prevention of concrete cracking.

◆Improve the flexural and splitting strength of concrete.

◆Improve the wear resistance and impact resistance of concrete.

◆Improving the impermeability of concrete.

◆Heat-Resistant,Abrasion-Resistant,,anti-aging.

◆Safe and easy to operate.

◆Construction is simple, economical and reliable.

Polypropylene micro fiber for concrete technical parameters:

Raw Material | polypropylene |

Origin | China |

Trademark | LUKE |

Type | Monofilament Fiber |

Density(g/cm³) | 0.91~0.93 |

Color | Natural(White) |

Length(mm) | 3、6、10、12、15、19mm |

Tensile Strength(MPa ) | >560 |

Elastic Modulus(MPa ) | ≥3000 |

Fiber Diamater | 25~45um |

Crack Elongation(%) | ≥15 |

Melting Piont | 160-170℃ |

NOTE:length size 3 6 10 12 15 19mm,as custormer’s requirements | |

Applying instruction for the use of polypropylene fiber in concrete cement mortar:

1、Choice of polypropylene micro fiber length:Fine aggregate concrete such as mortar is suitable for polypropylene micro fiber length less than 12mm, and coarse aggregate concrete is suitable for concrete above 12mm.

2、Compounding Amount:for resisting the common cracks on surface,0.9kg/m ³fibers to cement mortar are enough.

3、Ratio and mixing requirements:the proportion of cement,sand and aggregate is no need to be changed.Put cement,aggregate,additive and the polypropylene fiber(pp monofilament micro fiber or pp macro fiber) together,then stir after adding enough water and time for stirring can be prolonged for 2-3 minutes in order to make the compound mix completely.Also the Polypropylene fibers can be mixed even with cement and other aggregates in advance,striring by adding water at worksite before constructing.

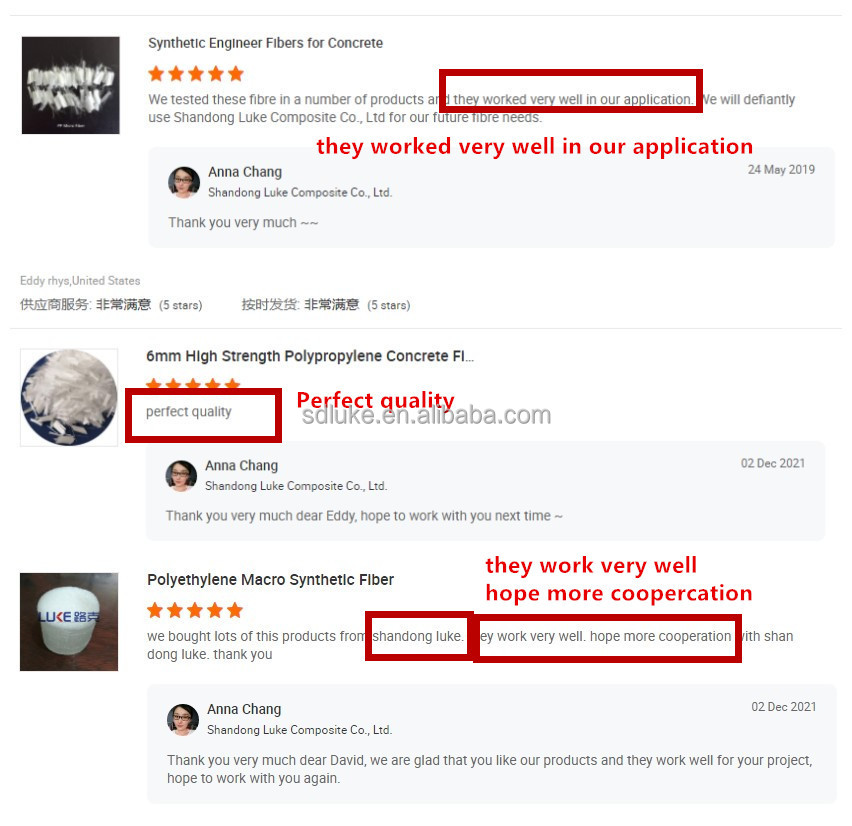

Customer feedback:

A good product, a customer recognition, this is our greatest success, thank you for our recognition, we will continue to work hard to improve the quality of service.

Packaging and delivery:

1 kg per small bag, 20 kg per big bag

special packaging can be supplied on your need

About us:

Shandong Luke composite Co ; LTD.is a professional company on production and sales engineering anti-crack fiber.

Concrete anti-crack fiber series such as PP fiber、PP mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber、basalt fiber etc.We can provide a sample of 1 kg.

Professional equipment, high quality polypropylene fibers series products, is your best choice,welcome to our company!

If you want to know more about the more fibers ,you can continue to ask me questions.

Our company aim is :Quality first!Reputation first!

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to polypropylene macro synthetic fiber in a timely manner. Thank you for your love of our products.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible