High Tensile Strength Concrete Polypropylene Macro Fiber

Concrete polypropylene macro fiber has high tensile strength.

It has good crack resistance.

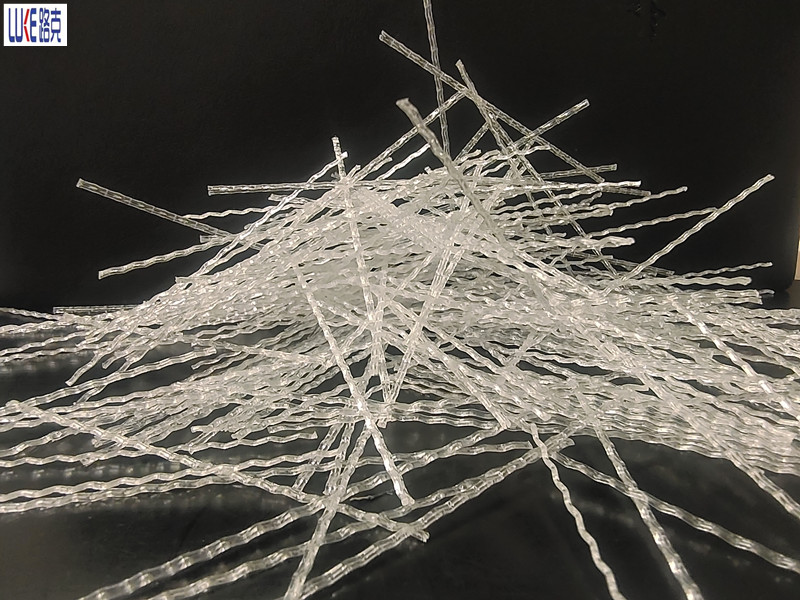

With 100% polypropylene fiber as its raw material.

Concrete pp macro fiber has good dispersion and high tensile strength.

It has advantages of acid and alkali resistance.

It can insteal of steel fiber with in concrete.

Polypropylene concrete polypropylene fiber is a new type of reinforced and toughened material.

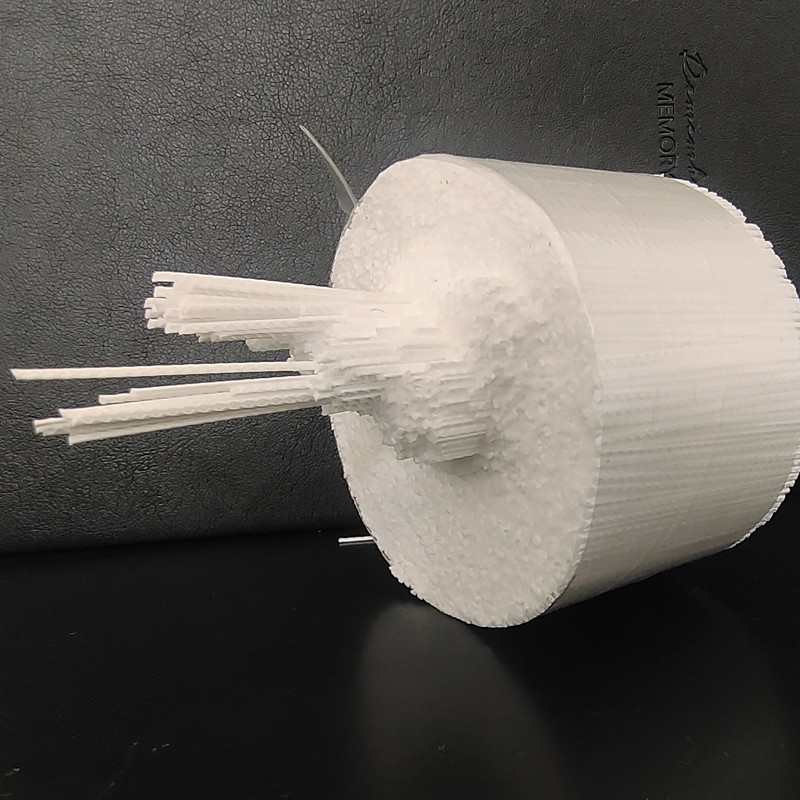

High Tensile Strength Concrete Polypropylene macro fiber

High tensile strength polypropylene fiber is a synthetic fiber made from polypropylene polymerization. The chemical structure of polypropylene fiber makes it have good heat resistance and chemical resistance, can maintain good tensile properties in high temperature environment, and can resist the erosion of some chemical substances. Because the excellent physical and chemical properties of high tensile strength polypropylene fiber, it is widely used in many fields.PP macro fiber price is low and economy and environmental protection.

The feature of concrete Polypropylene Macro Fiber:

◆Concrete fibers are used in concrete to increase wear and impact resistance

◆Polypropylene fiber has strong antioxidant properties

◆It has high strength, high stiffness

◆It has good impact and elasticity, and excellent buffer performance.

◆High toughness: PP Fiber reinforced concrete has good toughness, can withstand large deformation and is not easy to damage.

◆High temperature and chemical resistance : PP macro fiber concrete fiber has good high temperature and chemical resistance.

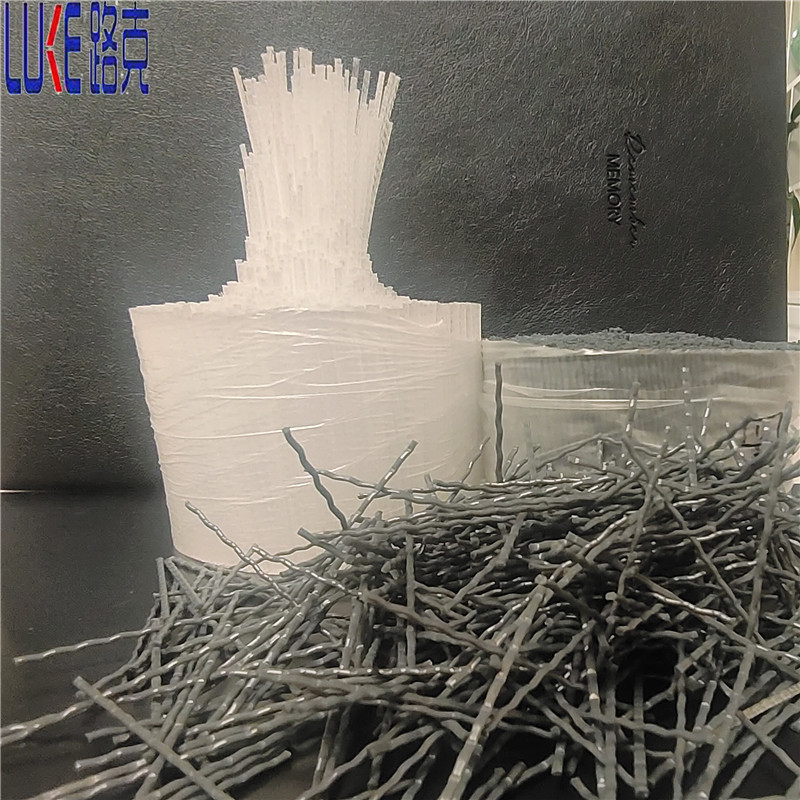

Concrete polypropylene macro fibers technical parameters:

Raw Materia | 100%Polypropylene | Length(mm) | 20~70 |

Trademark | LUKE | Tensile Strength | >500(MPa) |

Origin | China | Elastic Modulus | ≥4000(MPa) |

Shape | Curved,Embossed、Waved | Equivalent Dia | 0.9±0.2 |

Density(g/cm³) | 0.91 | Crack Elongation | ≥15% |

Color | White、Black、 Grey | Melting Piont | 160-170℃ |

Resistance Acid alkali | Strong | ||

Applying instruction:

Polypropylene macro fibers dosage:

More than 2kg/cubic meter of concrete.

Legth:50mm for general crack level,40mm for shotcrete.

Mixer:Horizontal Two-Shaft Forced Mixer.

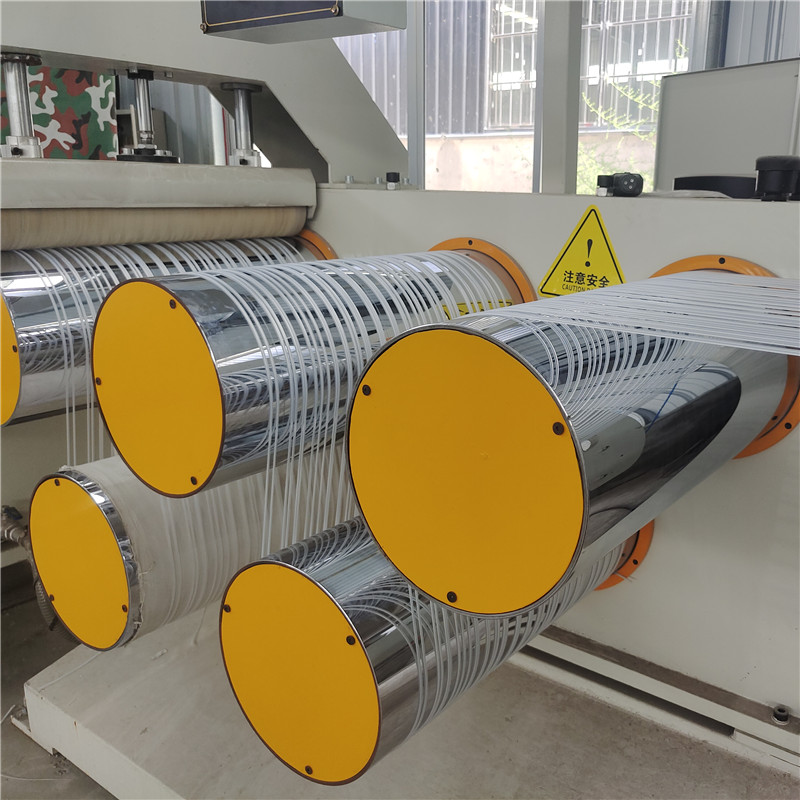

The production cycle of concrete fiber:

Quantity(kilograms) | 1-5000 | 5001-10000 | >10000 |

Lead time(days) | 5 | 8 | To be negotiated |

Packaging of pp macro synthetic fibers:

Packed in poly bag,woven bag,carton,oppbag,water soluble packaging,or at your request.

Plastic packing:1kg/plastic bag,20kgs/PP woven bag.

Paper packing:600-900g/paper bag,10-18kgs/carton.

Special packaging can be supplied on your request.

After-sales service:

Our company provides a one-stop service, and our staff provides 24/7 online support to solve any technical problems related to polypropylene macro synthetic fiber in a timely manner. Thank you for your love of our products.

Application:

◆It can used for spray engineering,concrete engineering

◆Concrete panel,factory floor,the wall of house,roof.

◆Surface of road and highway,toll station,tunnel.

◆Bridge Project,Water conservancy project.

◆Parking lot and wharf of the port,precast cement board etc.

About us:

Shandong Luke composite Co ; LTD.is a professional company on production and sales engineering anti-crack fiber.

Concrete anti-crack fiber series such as PP fiber、PP mesh fiber、PAN fiber、high strength and high modulus polyvinyl alcohol fiber(PVA),water-soluble polyvinyl alcohol fiber、curved pp macro fiber、twisted bundle pp fiber、steel fiber、basalt fiber etc.

Professional equipment, high quality polypropylene fibers series products, is your best choice,welcome to our company!

If you want to know more about the more fibers ,you can continue to ask me questions.

Our company aim is :quality first!reputation first!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible